Tips From Everseal Roofing On How To Hire Roofing Contractor

According to Everseal Roofing read company reviews before hiring roofing contractor!! Deciding on the right roofing contractor is a big decision and getting it wrong could cost more than just money. We dont want you to have any regrets. Here are some tips and ideas to help in your decision-making process: Get references and

Can A Rubber Roof Be Painted

EPDM Roofingrubber roofingcanpaintrubber roofpaintroof

. Hereof, does a rubber roof need to be coated?

Most rubber–coated roofs don’t need re-roofing for decades and need negligible maintenance. Rubber roof coating is often retailed as roof insulation and is commonly recommended by roof construction/remodeling providers. Rubber coatings also prevent homeowners from harmful rays like infrared radiation and UV rays.

Also Know, how do you paint rubber? For indoor items made of rubber that will not get a lot of wear and tear, use acrylic craft paint. You may need to use two coats, and be sure to let the paint dry thoroughly between coats. After the paint is completely dry, seal it. Find a paint sealer in the paint department at a craft or home improvement store.

One may also ask, can you paint over liquid rubber?

Liquid Rubber products cannot be applied to silicon, certain smooth or shiny surfaces, e.g. plastic piping and varnishes or oil based paints.

How often should you coat a rubber roof?

Even more so than other roofs, flat roofs require maintenance in order to last. This maintenance typically comes in the form of coating the flat roof. A lifespan of an un-coated flat roof is around 10 years but coating it every five years or so can extend this enormously.

Substrate Preparation For Roof Coatings

When applying roof coatings, remember that virtually all surfaces to be coated must be clean, dry, and free of contaminants such as dirt, oil, grease, delaminated areas of previous coatings, and other debris.

Do not apply roof coatings to wet or damp surfaces.

If you apply a roof coating to a dusty or damp surface, the coating will delaminate and fall off. Seen it happen a hundred times.

If a primer is recommended by the manufacturer, make sure you apply the primer!

You May Like: Solar Shingles Cost Per Square Foot

Applying Rubber Roof Coating To Your Camper

The protective sealant on a rubber roof will degrade over time, and begin to get chalky when cleaned. This is a clear sign that you should apply a coat of rubber roof coating to protect the rubber and extend the life of your campers roof.

After applying a the rubber roof coating, your campers roof is beautiful and white again. Unfortunately, a lot of prep work has to be performed before you can begin.

How To Apply Rubber Coating And Where To Pay Attention To

One of the great benefits of liquid rubber is the ease of application. There are only three basic steps to a liquid rubber application. Whether spray, brush, trowel, or roller, the coating will adhere to almost every surface concrete, stone, bitumen, EPDM, wood, PVC, metals, foam, tile, and zinc.

Step 1: PreparationA properly prepared substrate is paramount to the optimal application and performance of a coating. In the case of liquid rubber the substrate needs to be clean, dry, free from grease, dust, and other particles. Power washing the area is recommended. Cracks in the surface should be repaired beforehand for the best waterproofing result.

Note: Poor surface preparation may result in failure of the coating system adhesion is affected leading to preventing optimal performance.

Liquid rubber coating is also flexible regarding application: roller, brush, trowel and sporay are possible.

Step 2: ApplicationLiquid rubber should not be applied in temperatures below 5°C , nor when rain is expected within 24 hours, so make sure to check the weather. The coating can be applied with a brush, trowel, roller, or spray, and is cold applied. The minimum layer thickness for a waterproof membrane is 2 mm. When painting, the average coverage is 1 L per m2, yielding a 1 mm thickness. The coating is not applied in one thick coat but rather built up through layering.

Note: Always study the manufacturers instructions on application and obey them.

Recommended Reading: How Much Does A New Shingle Roof Cost

Benefits Of Roof Coating Sealants

Roof sealants dont serve just one purposethere are a handful of benefits you can get, depending, of course, on the type of sealing you go for. Heres a rundown of those.

The most important thing is to pick a pro who knows his or her way around roof sealants. They can pick out a quality product theyve used before. For a professional roof sealing, expect to spend an average of $1000but for an extra few years on your roof, thats a small price to pay!

Why Choose A Tank Spreader

- Efficiently apply any pourable material, such as adhesives and coatings

- Achieve even, consistent coverage with simple, gravity-driven application

- Accurately cover either flat or ribbed roofs without messy overspray

- Reduce waste with pre-drilled holes

- Enjoy simple clean-up and disposable or easy-to-replace parts

- Apply coating over metal roof panels using 14 Tank Spreader

- Easily purchase additional rollers

Customized rollers are also available for corrugated metal roofs

Read Also: Roofing Costs In California

Hire An Expert Rubber Roofer Near You

As with any other type of roof, hiring the right rubber roofing contractor near you is the most important step.

When installed correctly by a skilled Washington, D.C.-area roofer, a rubber roof can last 20 to 25 years.

But an incorrectly installed rubber roof will need to be replaced within just a few years. More importantly, a roof thats installed incorrectly can cause damage to the structure underneath.

If youre in the D.C. area and in need of a rubber roof contractor, contact us at Capitol Improvements for a free quote. We do both residential and commercial roofing.

How To Paint A Rubber Roof

While the flat roofing market has long been dominated by traditional tar and gravel, rubber roofing now accounts for up to 35 percent of the market according to RCI, a roofing industry association. As of 2012, black remains the most popular finish option for rubber roofing despite the superior energy efficiency offered by white roof finishes. Painting your rubber roof not only can give your home a fresh new look, but also can keep your home cooler and more comfortable by reflecting the sun’s rays.

You May Like: Skylight Installation Metal Roof

The Pure Advantages Of Applying Best Roof Coating

There are multiple supports that a person can easily take to use the coating on the roof. And durable, vibrant quality roof not only assists the top to stay longer but also forces less suffering you have for the future. So, invite yourself to get the full advantage of pure quality roof coating that is trending. According to U.S. climate and environment researchers, California now has 1 million solar roofs.

What Is The Best Paint For A Flat Roof

A high quality liquid rubber waterproof coating, Resincoat protects against leaks and corrosion. The liquid consistency of this product is easy to apply, making it ideal for flat roof repairs. With this DIY-friendly coating, you can apply it to a wide variety of substrates and it will adhere to them well.

Read Also: How Much Do New Shingles Cost

On Top Of Your Shingled Roof

Rubber roofing isnt only relegated to the field of flat roofs. It can also be used on pitched roofs, as a way to extend the lifespan of the existing roof structure and add value to the home.

On sloped roofs, rubber roofing is typically applied over the top of the existing shingles. A roofer can apply a layer of insulation onto the shingles, followed by the rubber membrane.

This option can save you money in the long run since rubber roofs tend to last longer than other types of roof replacement.

As an added benefit, installing a rubber roof on top of your shingled roof can dramatically lower your energy costs by insulating and deflecting heat away from the home.

Best Rv Roof Sealant & Coating Reviews & Recommendations 2021

More on RVing & Trailering

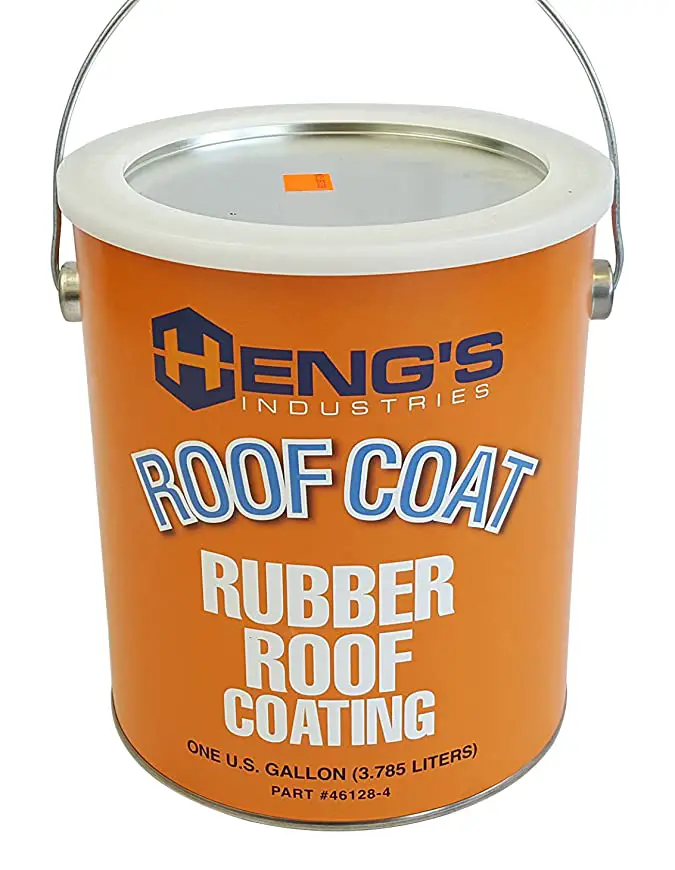

A favorite among mobile home and RV owners alike, Hengs roof coating is one of the best out there. Designed for use over RV rubber roofs, its ideal for sealing up and tears and cracks, and for waterproofing air conditioners and vents. The UV resistant formulation makes it stand up to the summer heat. Once applied, the coating will expand and contract with your RVs roof to resist cracking and degradation. Its also non-polluting and non-toxic, so youre protecting your health and the environment while using the product. The bright white colors make this a great pick for replacing Motor Coach rubber roofs. Overall, the product is really easy to work with, requiring fewer coats than the competition. The formulation is also safe to use in sunlight and wont bubble or crack even when freshly applied. A primer will help the formula go on even more smoothly, but its not required, saving you money in the re-coating process.

What we werent completely sold on was the fact that its an acrylic formulation, which means that its not going to be as long lasting as a silicone one. Its still a great product that does the job extremely well, but keep in mind that a couple of years down the line, youll have to re-coat your RVs roof again.

Recommended Reading: How Often Does The Roof Need To Be Replaced

Advantages Of Recoating Your Rubber Roof

When talking about rubber roofs, we mean roof coatings that retain a rubber feeling to them after curing. Silicone roof coatings remain extremely elastic after curing and appear to be rubber. There are also single-ply systems called rubber, but we mean silicone.

Now that thats addressed, lets look at recoating your rubber roof. Is this as big of a benefit as we like to say it is? Well, yes. We still believe recoating rubber roofs is a major benefit, but were going to show you why.

Aluminum Coating On Epdm Roof

I looked at a mobile home roof today that has a few leaks.

It is a rubber roof that was installed five years ago.

A couple of years later, the owner paid someone else to coat the rubber roof with that aluminum coating stuff. She swears she checked with a roofing company and they told her to have that done.

It is hard to tell, maybe the second guy just skipped large sections, but it seems that the aluminum coating is completely gone from large sections of the roof, while most of the roof is still coated and the coating seems to be well adhered.

I told her it is a crap shoot, since I have no way of knowing how the products I would be using to stop the leak will interact with the aluminum coating.

I think whoever told her to coat it with aluminum had their head up their

You May Like: How To Extend A Metal Roof Overhang

Pros Of Bowie Pvc Roofing:

- Even more flexible. The plasticizers and other chemical components of PVC rubber roofing make it even more flexible than TPO. This makes it resilient and resistant to building-settling.

- Time-tested product. Roofers have been using PVC for over 50 years. As a long-time industry favorite, its easier to find a roofing contractor who specializes in PVC roofing than in a newer product like TPO.

- Energy efficient. Like TPO, PVC is energy efficient and can help reduce your cooling bills during the warm summer months.

Benefits Of Rubber Roof Coatings

Coatings are a restoration option for EPDM roofs, and they offer various advantages, especially when compared to roof replacement. Coatings are notably affordable, and allow you to reinforce your structure for a mere fraction of the cost of a traditional replacement. In addition, coatings are applied over current structures, preventing tear offs and their subsequent landfill waste, and helping the environment. To review, benefits of rubber roof coatings include:

There are multiple types of rubber roof coatings, and it is not a one-size-fits-all process. For example, vulcanized rubber requires a specific type of coating that will stick to its thermoset material. If you are unsure about what coating you need, have no worries. The contractors from Roofers Guild will walk you through the entire process before any final decisions are made. If successfully applied, coatings can add 10 years to the roofs lifespan.

Don’t Miss: Rv Roof Repair Cost

Repairs Roof Leaks Faster

When EPDM rubber roof coating seeps into cracks, it fills in leaks and holes automatically. Over time, due to heavy foot traffic, leaks and ponding will occur on the surface of your EPDM roof.

Ponding is a common destroyer of EPDM roofs. It will cause great duress against the material. In consequence, it will penetrate the material causing internal leaks.

The EPDM rubber roof coating will help property owners conduct repairs for lightly-damaged roofs. In turn, it helps them cut down costs on unnecessary huge repairs.

EPDM roofs can be glossy or chalky. However, they lack a bit of aesthetic curb appeal

Protect Your Investment With Liquid Rubber Rv Rubber Roof Coating

Don’t let water damage ruin your RV keep your rig protected with professional-grade RV rubber roof coating from Liquid Rubber. Not only will regular applications of this high-quality top coat for RV roofs prevent costly water damage inside your 5th wheel, travel trailer or motorhome, but it will keep your RV factory-fresh and ready for your next adventure!

Also Check: Maximum Metal Roof Overhang Without Support

Which Roof Coating Performs Best

Its a question we get asked from time to time: which roof coating performs best? The short and simple answer isit depends. Thats because there are just too many variables to consider when it comes to the performance, longevity, and suitability of an elastomeric roof coating.

Below, we provide a comprehensive overview of the benefits, chemistry types, and physical properties to look for in an effective coating solution.

What Is Applied Rubber Roofing

Applied rubber roofing is a thick coat of rubber that can be quickly and easily applied to the surface of your buildings roof with a roller or professional-grade sprayer.

Liquid rubber is usually referred to as instant set because it dries very quickly and takes shape immediately.

The application process is very similar to painting and can be completed much more quickly than a typical roofing job involving shingles.

Read Also: Roof Replacement Cost In California

The Top 6 Reasons To Use Rubber Coating

The reason for the continued success of liquid rubber coating is simple: in terms of waterproofing it outperforms the alternatives. This is why one of liquid rubbers most important applications is flat roofing. The qualities that make liquid rubber coating the choice for waterproofing are:

How Long Do Rubber Roofs Last

Rubber roofing, when installed professionally, can last 25 years or more. TPO and EPDM roof systems have similar lifespans of 20 to 25 years.

High-quality TPO roofing that is reinforced with fiberglass can last even longer. Modified bitumen roofs last an average of 10 to 12 years, and built-up roofs last between 15 and 20 years.

You May Like: Cost To Reroof A House In California

Buy Liquid Rubber In Canada

Rubber coating is available from suppliers across Canada, for all projects big and small. There are contractors up and down the country who provide liquid rubber installation services for roofing, waterproofing, industrial rubber coating for metal, and any other project you may have. If you wish to buy rubber coating, or would like to be connected with one of our partners, do not hesitate to contact us! Our experts are happy to help, just make use of our free quote service to find the right coating solution for your project.

Flex Seal

Epdm Coatings Cost Compared To The Competition

EPDM coatings has been featured in Article Insider, as well as Roofers Exchange, Building Service Management and recently won Metal Roofing Magazines product of the year. EPDM coating products have always been made right here in the USA. In addition, we source our suppliers from the USA as well. The product comes with the catalyst already in the can. Simply mix the product with a drill mixer and you are ready to apply. Application is with a 3/8-inch nap roller. Simply put the lid on the product to avoid air getting to it to avoid the curing process. For any material left in the can, fasten the lid tightly and you can store it for up to four years. For best results, the product should be applied between temps of 50-100° Fahrenheit. If you are using spray equipment then 70°. The product requires daytime temperatures of at least 50° to cure. Temperatures can fall below 50°, and once they rise again above the 50& deg it will continue to cure. Any non-opened container can be stored up to four years without it losing its properties. Roof leak repairs are an unwelcome reality to every owner of a residential or commercial building, mobile home or recreational vehicle. Roof leak repairs can involve almost anything, including replacing damaged shingles, mending holes, fixing roof leaks, or repairing dents with roof coatings.

You May Like: Where Do You Put The Screws On A Metal Roof