Corrugated Screw Location For Wall Panels Or Metal Siding

There will be five panel screws and one lap screw per screw line. The lap screw is the screw that sits in the high and it is designed for a light gauge metal to light gauge metal connection. Lap screws are spaced 12 to 18 on center. The panel screws are spaced out so that every third corrugation has a screw including both sides of the panel sidelap. When the corrugated sheeting is 39 wideinstead of 37 wide the screw placement will be slightly different as shown in the diagram below.

We recommend that you use double sided mastic tapeat the panel sidelap for a wall condition also. The mastic tape will make the panel more weathertight. Mastic tape is always used for a metal roofing installation. On a wall application, mastic tape is shown in our installation guide and we do recommend that its used. The reality is many installers choose not to install the mastic tape for wall conditions.

Screw Line Spacing For Metal Roofing Over Metal Purlins

This will depend upon the type of panel that is used and the thickness of the steel. An engineer will use a load chart in order to determine the spacing between metal purlins. Once the purlin spacing is determined then the metal roofing panels are typically attached to every line of purlins. If the purlins are really close it might be possible to attach the metal sheeting at every other purlin. However, that would be a decision for the engineer.

How To Estimate Metal Roofing Panels

A metal roof is one of the most durable material options for your home. When ordering supplies, it is important to estimate materials correctly to allow for an efficient installation process.

Estimating the amount of metal roofing material you need starts with estimating the square footage of the roof itself.

Get Free Project Estimates

Find Qualified Roofing Professionals in Your Area

You May Like: Does House Insurance Cover Roof Leaks

Corrugated Aluminium Roof Panels

Corrugated Aluminium Roof Panels Details: Color: Silver Shape: Aluminum Panel Application: Roofing Sheet Material: Aluminum 3003 Feature: Moisture Proof Aluminum roofing is the system most qualified to perform in the extremes of wind, heat, humidity, and precipitation in all areas of the country. Al roofing panels are often chosen by homeowners and architects for a variety of applications from residential homes to sm …

Measuring Or Calculating Gable And Hip Lengths

The slope factor is also used to determine gable lengths when the run length is known. For example, in Figure 4 the bottom left gable measures 16 across from eave to eave and therefore has a run of 8. When this is multiplied by 1.202 the gable distance is 98 . Note that this run can also be multiplied by the hip/valley factor of 1.563 to get a valley length of 126.

Record all your calculations on your drawing as seen in Figure 5 below.

Figure 5. Completed Roof Plan Drawing

Pro Tip: A Note About Waste Factor

Once you have figured out your roof area, you will need to also calculate how much room you need to allow for waste. For metal roofing products on a medium complex roof a waste factor of 15% is advisable. In other words for the 2468 ft2 roof in our example you should multiply by 1.15 giving you 2838.2 ft2 roofing material needed.

Important Note: Most metal roofing products are packaged and sold by the square so for our example roof the number of squares or boxes to purchase is 29.

Also Check: Is Roof Covered By Home Warranty

Cost Of Aluminium Roofing Sheets In Nigeria

Gone are the days when people didnt really care about the type of roofing sheets they use for their buildings. Some would rather even use random materials to just act as covering for their houses irrespective of how long they last. Today, roofing sheets have gone beyond just providing shield for buildings, they now have a way of beautifying a structure, showing elegance in their own style. With the market of roofing sheets growing, it is important to take a look at some of the best types available, one of which is the aluminium roofing sheets.

If beauty and ruggedness are factors you consider when deciding on a roofing sheet to use for your building, then aluminium roof sheets should be at the top of your list. Apart from the fact that this type of roofing sheet does the basic work of shielding the building, it adds beauty and attractiveness to the whole structure in its own style. No wonder it is one of the most sought after roofing sheets in Nigeria.

Aluminium roofing sheets are among the most rated roofing sheets for lots of reasons. They are durable, reliable and compared to some other types of roofing sheets, they rarely leak and are not corrosive. This doesnt fly without the mention of the sheets long lasting characteristics. They might not be the best and most expensive roofing sheets in the country, but they sure are among the most effective and reliable.

Contents

Longspan aluminium of 0.70mm thickness costs N5,500 per meter

Obtain The Length And Width Of The Metal Sheet You Want To Use

Now its time to obtain the length and width of the metal sheet. You can obtain it directly by visiting a shop and directly measuring the metal panels. The standard sheet metal width is 26 inches, and the length varies from 8 feet to 24 feet.

There is also another method to determine the length of your metal panels. You need the distance from the fascia board to the peak of the roof. This space will tell you the length of the metal panel required.

Now whatever measurement you come out with, add one or two inches to it because some people want to overhang the metal panels for aesthetic purposes. Suppose you get 21 feet or 252 inches, then add two inches to it. So now, the length of each metal panel will be 254 inches.

If your metal sheet is 26 inches wide and 22 feet long, then the total area of that metal sheet is 572ft2.

Recommended Reading: Where Can I Buy Roofing Shingles

How Do You Repair A Roof Sheet

Clean the surrounding area so it is free of dirt and debris. Scrape off any loose or flaking roof coating with a putty knife. Apply one or two inch strips of butyl tape around the perimeter of the patch area. Cut a patch out of galvanized metal to a size that overlaps the hole by two to three inches on all sides.

Also, how do you remove roofing sheets? Pry the edge of the sheathing from the roof rafters while standing on an adjacent sheet. Move the pry bar down the rafter to remove the nails if you can’t pull the sheathing up by hand after prying it away. Once the sheet is free, carry it down the roof and drop it onto a clear space of the yard or other surface below.

Keeping this in consideration, how do you repair asbestos roofing?

How To Repair small cracks in asbestos roof or cladding panels.

How do you calculate roofing sheets?

Multiply the length of the roof by the width to establish the surface area in square feet. For example, if the length is 21 feet and the width is 10 feet, the surface area is 210 square feet — 21 times 10 equals 210. Determine the width and length of the metal sheets to be used.

Tips For Getting Started

Tip 1: Measuring to the nearest inch along eaves and across gables can be done from the ground just dont forget the overhang.

Tip 2: If you know the dimensions of your previous asphalt roofing job, you can use this info to cheat a little. Typical 3 Tab asphalt shingles have tabs that are 1 foot wide with a vertical exposure of 5 inches. Make sure to physically verify these dimensions by measuring 4 or 5 courses. Counting the shingles can give you eave to ridge dimensions from the ground.

Tip 3: 100 Square Feet = 1 Square in Roofing Terms

Also Check: What Should Be In A Roofing Contract

How To Calculate Metal Roof Cost Metal Roof Formulas

Although our metal roof calculator will do all the work for you, we understand that you may feel more confident if you know how to carry out the calculations yourself. Here are detailed instructions on how to calculate metal roof cost on your own.

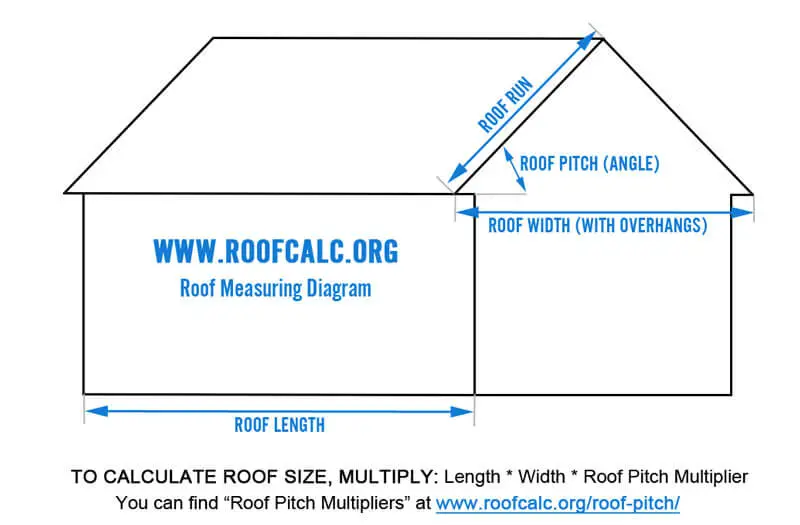

- calculating roof area based on roof measurements: roof length * roof width = roof area

- calculating roof area based on footprint measurements: footprint length * footprint width * roof pitch multiplier = roof area

- calculating panel area: panel length * panel width = single panel area

- calculating number of panels to buy: roof area / panel area = panels needed

- calculating the cost of buying the panels: cost of a single panel * number of panels = total expenses

Exposed Fastener Metal Roofing Panels

The hardy rib panel is the most common exposed fastener metal roofing panel and comes in 3 ft wide panels, cut to any length you want. This is an exposed fastener roof meaning that you will see the screws when you have completed your roof. The most common screw pattern used is 24 inch on center. Meaning every 24 inches up the panel you will place another line of screws.

Also Check: How Much To Replace A Roof Per Square Foot

How To Calculate The Number Of Iron Sheets

Now find out the length and breadth of each roofing sheet and also multiply length by breadth. Assuming the ceiling sheet is 3 m in length and 1m in breadth,

Then area of roofing sheet =3 x 1 = 3m2

Therefore total numbers of roofing sheets needed approximately is/area of one roofing sheet

=82.8/3m = 28 Mabati Sheets

Please note that this is not a standard way of approximating but this is derived based on site experience. In any case there is no particular standard way.

With your estimate is also the Ridges, Valleys and Gutters.

Ridges and Valleys are the roof materials you use that will cover and seal up the points where two leaves of your aluminium sheets meet to protect the interior from rain, it usually overlaps the two adjacent leaves of roofing sheets .A gutter is usually underneath, it gathers rainfall and help to channel it to wherever deem fits according to design. Is at the taper ends of two adjacent leaves of aluminium sheets to collect water.

The difference between gutter and ridge . While the ridge is up protecting rain water the gutter is down collecting rain water and channeling to some drains.

More Resources On Metal Roofing Installation

Screw placement for metal roofing and siding panels is easy. After you view the videos and diagrams in this article you will not have any issues. If you are learning about screw placement then the next steps is to learn more about fastening the metal sheeting and trim and flashing installation. An excellent starting point would be to view our installation guides or watch our installation videos.

The first piece of trim that will be installed on your metal roof is the eave trim.

We created an EASY step by step installation video to make your metal roofing installation as simple as possible.

Discover which type of fastener is right for your metal roof installation by reading:

Also Check: How Much To Repair A Trailer Roof

S To Estimate Metal Roofing

Measure the length and width of each roof section in feet, then multiply together to get the square footage.

If you are unable to crawl on the roof, you can estimate by measuring the roofs footprint and finding its square footage. Multiply the footprint square footage by the multiplier for your roof pitch to find the actual square footage of the roof. Use our roof pitch calculator to find the pitch of your roof.

Next, find the square footage of the metal roofing panels you want to use. Measure the length and width in feet, then multiply together to find the square footage. Panels are often measured in inches, so you can use our inches to feet conversion calculator to convert to feet.

Finally, divide the square footage of the roof by the square footage of the metal roofing panel to find the number of panels needed for your roof. Its a good idea to order an extra 10% to account for cutoffs and waste material.

For more complex roofs with many peaks and sections, find the square footage of each roof section and add them all together to find the total square footage. Consider ordering a few extra panels to account for more cuts and waste.

Calculate The Complex Roof Areas

Most roofs in Canada would be considered on the complex side. Multiple adjacent pitches, dormers, and turrets are common. Keep in mind that an experienced metal roofing contractor will need to factor in extended labour time for areas of your roof that will require precision metalworking skills.

Start by finding the footprint area and multiply by the correct slope factor determined by pitch . In Figure 4 below, the dashed blue lines give a simplified view of the footprint. Multiply L x W to calculate the area for each rectangular section. Note the area of 77ft2 that needs to be subtracted for the recessed area.

Once the footprint including overhang areas have been determined for each area, find the appropriate slope or pitch factor in the chart below. For example, a roof area with an 8/12 pitch has a slope factor of 1.202 so 2053ft2 x 1.202 = 2468ft2 total roof area.

A Note about complex roofs: Complex roofs need more accessories and trims thaneasy roofs resulting in a slightly higher total cost/square foot.

Figure 4. Calculating Complex Roof Area

Also Check: How To Install A Swamp Cooler On The Roof

How Many Screws Will I Need For My Metal Roof

The vast majority of the jobs that we sell are fastened at 24 on center . Therefore, we will base this answer upon 24 O.C. screw lines. If your screw lines are closer or further than 24 O.C. you can make some adjustments based upon this formula. We are also referring to these specific 36 wide panels: Corrugated, R Panel or PBR Panel, and 7.2 Panel or Western Rib.

Find The Area Of A Roof

Multiply the length of the roof in feet by the width of the roof in feet to find the area of the roof in square feet. If you have multiple sections of roof find the area of each and add them together to find the total area.

If your roof is not flat and you cannot climb to the peak to get accurate width measurements then you can add a multiplier for the pitch of your roof.

Use our roof pitch calculator to find the pitch of your roof or find the pitch multiplier, then multiply the area of the footprint of your roof by the multiplier to find the actual area.

Alternatively, find the area of your roof using our roofing calculator, which can also estimate shingles and material needed for your project.

Get Free Project Estimates

Find Qualified Roofing Professionals in Your Area

For example, if your roof is 30 ft by 50 ft, then the area is 1,500 ft2.30 × 50 = 1,500 ft2

If your roof has triangles and other shapes youll need to use a calculator to find the square footage.

Read Also: Does Replacing A Roof Increase Home Value

How To Calculate A Corrugated Metal Roof

Related Articles

Corrugated metal roofing is used through out the world, from Alaska to Australia to India. Its appeal owes much to the simplicity and strength of the material, as well as its availability and low cost. Corrugated metal sheeting is available in different thicknesses, styles and sizes, but regardless of the shape and size, the sheets must be overlapped, like roofing tiles, to provide a continuous and watertight finish, with no gaps through which weather can penetrate. The overlap must be taken into account when determining how many sheets to use.

Determine the length and width of the area requiring a roof. Obtain the dimensions from the builder’s plans or stretch a tape measure along the structural members of the roof to directly measure the length and width. Record the values.

Add on any required overlap at the edges, then round up the dimensions to the next larger foot to simplify calculations. For example, if the measured length is 19 feet 10 inches, and an additional overlap of 6 inches is required at both ends, the final figure will be 21 feet — 19 feet 10 inches plus 6 inches times 2 equals 20 feet 10 inches, which is rounded up to 21 feet.

Multiply the length of the roof by the width to establish the surface area in square feet. For example, if the length is 21 feet and the width is 10 feet, the surface area is 210 square feet — 21 times 10 equals 210.

Tip

Warning

References

Metal Roof Cost Calculator

If you’re wondering how to calculate metal roof cost, this metal roof cost calculator is the right tool for you. Use it to find the area of your roof, determine how many metal panels you will need, and estimate how much does a metal roof cost. Plan your work in advance and enjoy having your time saved by this handy calculator.

Recommended Reading: What’s On My Roof