Do You Need Flashing At Bottom Of Siding

When more than one length is needed to span across the bottom of a wall, overlap pieces at least 8 inches. The flashing must include a drip-edge to direct any water that runs down the drainage plane away from the bottom of the wall. 8-inch minimum between siding and grade.

How To Install Vent Pipe Flashing On An Existing Roof

The last thing you want to deal with is a leaky roof. Your life is busy and hectic enough already that you dont need another thing to fix. Remaining proactive and putting in things to prevent leaks in the first place is the best way to stop a leaky roof before it starts.

If not, it can cost you thousands of dollars to fix. If you decide to add a fireplace or stove to your home, youll want to add vent pipe flashing to prevent leaks. The process is easy, and you dont need any special skills to get the job done.

The DIY project consists of loosening shingles, putting on the flashing, and nailing it down. Its really that simple! Its always a good idea to finish with a roofing cement to seal any cracks or crevices.

This article is going to teach you everything you need to know about installing a vent pipe flashing on an existing roof. Well go over step-by-step instructions, the different types of flashing, and more.

Understanding The Difference Between L

Essentially, both of these types of flashing do the same thing they help guide water away from seams and joints in your roof, preventing water from soaking through your shingles, or in-between vulnerable joints.

L-shaped flashing is, as the name may suggest, shaped like an L, built with a simple 90-degree joint that flares out at the bottom. The L shape hugs the side of your roof tightly, while the flared base pushes water away from your siding, keeping your home more dry.

T-shaped flashing is slightly different. Shaped like an elongated T, this flashing attaches to the roof and projects outward, with a downward projection that sits an inch or two outside away for the side of your home.

The increased distance between your home and the flashing itself makes T-shaped flashing, a better overall choice when youre going to install flashing on an existing roof. Water will run more smoothly across the flashing, and be pushed farther away from your home, helping you avoid excess moisture that can damage your siding.

Also Check: Extending Roof Overhang

Basics Of Installing Step Flashing On A Roof

Flashing is a solid, waterproof material that prevents water from entering seams or joints in a building. Step flashing is a flashing variation that builds upward along the roof pitch, using small pieces of flashing that are interwoven with the shingles. Step flashing is usually some type of metal aluminum and copper are popular, but stainless steel and lead are used, as well.

With roofing systems, any kind of joint or seam is an invitation for potential water leakage. Where the roof meets a wall or other upper vertical surface such as for a dormer, the problem is pronounced. Water coursing off of the wall collects in the 90-degree intersection between the wall and the roof. When snow banks up in that area, subsequent snowmelt can linger and eventually seep between the wall and the roof.

Sealing the shingles to the wall with tar, caulk, or other liquid products is a fix that rarely lasts long. Eventually, these types of sealants fail, permitting water into the home. L-shaped step flashing is flexible enough to move with the home as it expands and contracts yet it is solid enough to hold back water.

Continue To Install Cap Flashing

Cut the side cap flashing to fit the angle of the roof so it overlaps each lower cap flashing at least 2 in. Pound the flashing into the grooves and fasten with the drive-in expanding anchors. Bend a piece of cap flashing to fit around the top corner of the chimney and add the cap flashing across the back of the chimney.

Don’t Miss: How Much Does It Cost To Recoat An Rv Roof

Installing The New Vent Pipe Flashing

Now it gets a little tricky to install the new vent pipe flashing you first need to work the opening of the rubber where the pipe will pass through by stretching it. You just want it flexible so the pipe will pass through easily.

Now put a small amount of silicon on the inside of the rubber flashing and spread it around so it will slip over the pipe without problem.

Lower the flashing onto the pipe rotated 90 degrees or the opposite way that it came off.

At the same time you want to lift the top two rows so that the metal flashing can be rotated under the middle row of shingles.

BEFORE the flashing is pressed down to the surface of the roof you want to apply a bead of silicon on the shingles about an inch in from the edges.

Now press the aluminum flashing flush to the shingle surface.

Nail the bottom two corners about an inch in from each side the same position as when you took the flashing off.

Nail the two middle edges of the flashing.

Nail the top shingles in place through the flashing on the outside corners.

Benefits Of Step Flashing

The main benefit of step flashing is providing structural integrity to your roof. Since water leaks easily seep in the sidewall and are one of the most vulnerable areas, step flashing prevents this from happening.

As a result, its advised that you shouldnt skip on flashing installations just to cut down costs. Without it, water leaks damage your roof structure and also result in mold & mildew growth.

Don’t Miss: How Much Does It Cost To Shingle A Roof

How To Install Flashing Under Siding

Flashing is a key part of the LP® SmartSide® Trim & Siding installation process, helping to protect homes from the elements by helping to prevent moisture intrusion. When you are installing lap siding, incorrectly installed flashing may lead to moisture issues that can affect other aspects of the home in addition to the siding.

We talked with Isaac Ojeda, Construction Service Associate at LP Building Solutions, to learn how to install flashing under siding and about some flashing and siding installation mistakes. Follow these tips for installing flashing and to help your builds stand strong for years to come.

How To Install Step Flashing

Before we dive into how to install step flashing, here are two key reminders to take note of before you start:

Don’t Miss: How Much Does A Roof Cost In California

Choose The Right Flashing Material

There are several flashing materials on the market, including copper, galvanized metal, and aluminum. However, most DIY homeowners prefer aluminum as it is easy to install.

In a nutshell, lets look at the features of the various roofing materials.

- Aluminum: Aluminum is soft and easy to manipulate, making it a famous roof flashing material. However, it may need to be coated when being used in alkaline environments to prevent corrosion.

- Pre-Bent Steel: Steel is another excellent material for roof flashing because of its numerous benefits. It is malleable and corrosion-resistant when galvanized. Its aesthetic value is another reason many homeowners love it.

- Copper Metal: Copper is the premium choice for flashing installation projects. It is malleable and soldiers easily. Copper can also discolor over time when it patinas, which may be beneficial for some homeowners.

Before selecting any of the roof flashing materials, check if the local building codes allow you to install the material of your choice. Some building codes may specify the materials for flashing in their regions and the minimum thickness required.

Mastering Roof Inspections: Flashing Part 2

The purpose of the series Mastering Roof Inspections is to teach home inspectors, as well as insurance and roofing professionals, how to recognize proper and improper conditions while inspecting steep-slope, residential roofs. This series covers roof framing, roofing materials, the attic, and the conditions that affect the roofing materials and components, including wind and hail.

ROOF-WALL INTERSECTIONS

Places where roofs and walls intersect are very common. Theyre called headwalls and sidewalls.

A headwall is a level junction where a roof meets a wall.

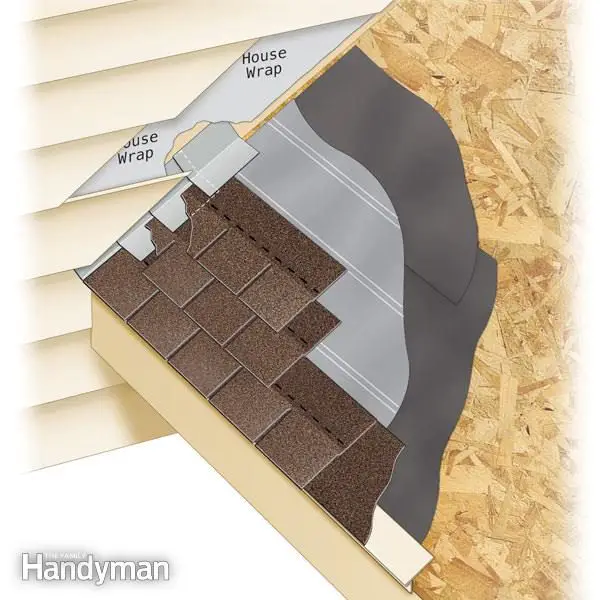

This illustration shows proper flashing at a headwall condition.

Headwall flashing should extend up behind the exterior wall covering and down over the roof-covering material, as you see here.

This is true no matter what type of roof-covering material is installed.

Flashing should overlap the roof-covering material, but on asphalt shingle roofs, for aesthetic reasons, the part of the headwall flashing that extends down over asphalt shingles is often covered with a course of shingle tabs.

Dont mistake this condition for headwall flashing routed beneath the shingles and call it a defect.

Occasionally, youll see a roof which has had 90°-sidewall flashing installed as headwall flashing. These dont bend well to accommodate roofs with steeper pitches, and youll often see gaps beneath the flashing. Wind-driven rain can enter at these gaps, causing roof leaks.

SIDEWALL FLASHING

Step Flashing

Tile Requires Pan Flashing

You May Like: Skylight Installation Metal Roof

Should You Hire A Professional Roofer To Install A Vent Pipe Flashing

There are times youll need a professional roofer to install a vent pipe flashing, and there are times you wont. Depending on your roofs condition, some vent pipe flashing installations are straightforward, while others require professional intervention.

If youre new to roofing, you should wait until your skills improve before attempting this installation on your own. But if the project isnt too complicated, dont shy away from giving it a go yourself.

Alternate Flashing And Shingles

Lay a shingle over the step flashing starting at the roof edge. Fasten that shingle with two galvanized nails at the top, then cover the top of it with another piece of step flashing, nailed to the wall. Work up the roof in steps, covering each end of flashing with a shingle and each end of a shingle with flashing, so there are no open seams. Alternate flashing and shingles to the roof peak, advises Fine Homebuilding.

Read Also: Cost To Reroof A House In California

Start With The Ice Barrier

In climate zones prone to ice damming, code requires that a self-adhering ice barrier membrane be applied directly to the sheathing so that it extends from the lowest edges of all roof surfaces to a point not less than 24 inches inside the exterior wall line of the building.

That 24 inches is measured horizontally from the inside edge of the wall and so the overall dimension from the roofs edge depends on your roofs pitch and your eave depth. Silva likes to go beyond the 24 inch minimum to 36 inches from the inside wall.

Due to the location of this roof, which will receive runoff and snow from adjacent roofs, Silva ran the ice and water membrane all the way up the roof , lapping it up the sidewalls.

He also carried the self-adhering membrane over the joint where the fascia meets the sheathing. This ensures that any backup that happens like from ice bridging the fascia and gutter wont creep under the sheathing, which would cause rot.

Note: In this video, Silva used a granulated ice and water membrane. In order to ensure that the lap over the fascia and sheathing remained intact , he used a non-granulated bituthene membrane to seal the joint.

Diy Vent Pipe Unclogging

If you decide to unclog it yourself, start by cleaning any debris around the vent pipe. Remove any blockage you come across and use a plumbers snake if you find any debris that you cant reach. Feed a hose down the vent and carefully turn on the water to push the remains down the drain.

If youve never done this before or are unsure where the problem lies, its always best to leave it to a professional contractor. You can find verified and trusted plumbers on popular sites such as Angies List or similar internet services companies. A professional can save you from potential injury and ensure a clean job.

Read Also: How To Install Snow Stops On Metal Roof

Recommended Reading: Roof Cost California

How To Find Your Roof Slope

Find the slope of the roof. Label one edge of a 2-ft. square scrap of plywood or cardboard roof and lay the labeled edge against the roof. Draw a level line at least 12 in. long on the plywood and label the line run.

Measure 12 in. along the run line and make a mark. Use a framing square to draw a square line from this mark down to the edge of the plywood labeled roof. Label this line rise. Measure the length of the line labeled rise to determine the slope, expressed as inches of rise for every 12 in. of run. In our case, the roof slope is 6 in. of rise for every 12 in. of run.

When To Call A Professional

Flashing a roof is no simple task and requires roofing experience as well.

In addition, this step is so vital to your roofing structure that poor installations can easily lead to repeating the installation process all over again, which doubles your costs.

If you have plans of installing step flashing on your own, we recommend calling a professional first to assess any roof leaks and which areas need the highest priority and urgency.

Installing flashing on roofs does take skill, and it can also be tricky to install. If there are any gaps , water will leak through and damage your roofing structure.

Improper roof flashing installations can also lead to potential danger for your roof during winter.

When the snow on your roof melts and then freezes over again, this cycle of melting and freezing will cause the ice to back up between the gaps & cracks of the flashing and penetrate your home.

Also Check: Average Shingle Roof Cost

S To Install Flashing Under Siding

Follow this simple step-by-step process for installing lap siding with pan flashing at butt joints. This installation process is approved for LP SmartSide ExpertFinish prefinished siding only. Ensure the ends of the siding are factory finished for this flashing method. Heres how to install flashing under siding:

How To Install Step Flashing On Your Roof

- Working Time: 1 hr, 30 mins

- Total Time: 2 hrs

- Yield: 6 feet of step flashing

- Skill Level: Intermediate

- Estimated Cost: $50 to $75

An effective system of step flashing on a roof is crucial to maintaining not just your roof but your entire home. Mold, rot, insects, and structural failure are the main byproducts of moisture intrusion inside walls, attics, roofs, and floors. Learn how to install step flashing to keep your house dry and in good condition.

Don’t Miss: Travel Trailer Roof Repair Kit

Lay Down The Shingles

Once youve installed the flashing pieces, install a row of shingles covering the roof and a piece of seam flashing. The first shingles end should extend over the flashing and onto the flat section of the corner flashing piece.

Install the next flashing piece, ensuring that the bend lies in the seam between the roof and the house. The bottom edge of the piece should end immediately below the nail line of the shingles you just laid. Nail the upper part to the wall in the upper corner.

Continue up the roof in that manner as you alternate the flashings with rows of shingles. Make sure that the nails are not visible, except the last one hammered.

What Is The Warranty On This Product

Our chimney kits are backed by a 20 year limited warranty, which covers any defects in materials and workmanship from date of purchase. Please note that damages caused by improper installation or other modifications will not be covered under our warranty agreement. Damage to your property may also cause an exclusion from our warranty agreement.

Don’t Miss: Shed Eave Overhang

How To Install Roof Flashing In 2021

Roofers use roof flashing to ensure no water leaks into areas of roofing features like vents, chimneys, dormers, skylights, etc. Its critical during roof installation to avoid any damage in the future and helps uphold the integrity of a new roof.

However, flashing may need to be replaced throughout the lifespan of a roof, so we will walk through the steps of installing or replacing roof flashing. Pay close attention to keep your roof safe from leaks and water damage.