How Much Does A Metal Roof Panel Weigh

You might be surprised to hear that the weight of most metal roofing per square foot is under two pounds, which is on-par with many forms of asphalt shingles. Shingles, on average, will weigh approximately two pounds for each square foot, while steel, the heaviest of the metals used for roofing, weighs in at about 1.5 pounds per square foot. Should you choose copper or aluminum roofing instead of steel, the numbers are even lower, at 1.25 and 0.7 pounds, respectively.

How Do You Measure Sheet Metal Thickness

You can find the thickness of your sheet metal by using a measuring tape and a simple conversion technique. First, use the tape measure to find its thickness in millimeters. This helps get the most accurate measurement. Second, multiply the number of millimeters by 0.03937. If your original measurement was 40 millimeters, the new one would be 1.5748 in inches.

Also Check: Exposed Fastener Metal Roof Screw Pattern

What Is The Screw Pattern For Corrugated Metal Roofing

The screw placement for corrugated can be a little tricky. The fasteners are located in different locations for roofing and metal siding conditions. Then if that wasnt confusing enough metal roofing manufacturers have differing opinions on the correct corrugated screw placement for a roofing condition. Hang in there and we will explain this one to you in detail.

Just in case you are a visual learner we created this easy step by step video also.

There are two schools of thought when it comes to corrugated metal roofing screw placement. Both are correct.

If the fastener is placed in the low of the panel it partially obstructs water and debris. The low of the panel is skinny and the fastener takes up most of that space. As the water drains it will go over the screw. Screws that have backed out over time or that were installed incorrectly will leak. You will avoid the bulk of this issue by installing the fastener in the high of the roofing panel.

Also Check: Are Roof Repairs Covered By Homeowners Insurance

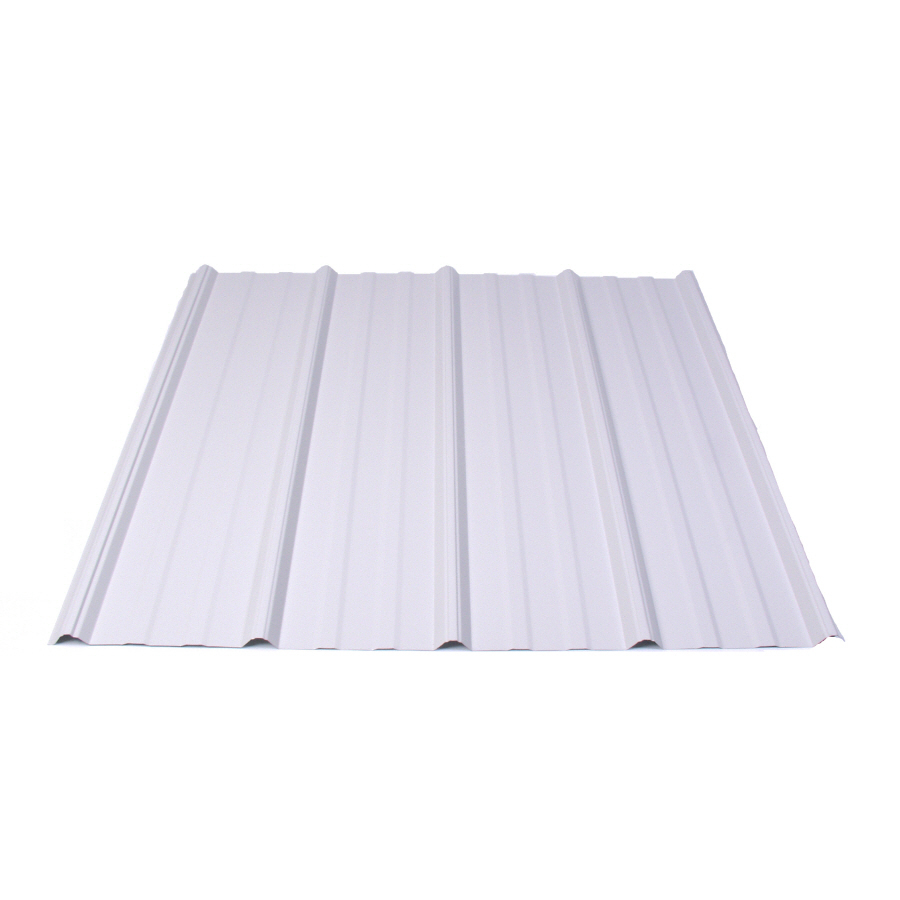

How Wide Is A Metal Roof Panel

By: Author Ryan M.

A metal roof panel is a great way to extend the life of your roof. Metal roof panels come in different widths and lengths, so you can find one that meets your needs. But how wide are these things?

This post will give you some insight into what size metal roof panels are available on the market today!

Is It Possible To Put A Metal Roof Over Shingles

Metal Roofs Can Be Installed Over Existing Roofs If local building codes allow it, metal roofs can be installed over existing roofs without tearing off the shingles. While shingle removal is preferred, tear-off is messy and increases the cost of the job. Metal roofing can be installed over existing roofs.

Read Also: What Is The Cost Of Roofing Per Square Foot

Is It Cheaper To Get A Metal Roof Or Shingles

A metal roof is often more expensive to purchase and install than asphalt shingles. Since they last longer than asphalt shingles, you may not have to replace them as often, so it may be worth the investment to save money in the long run. With those factors in mind, a metal roof can be cheaper than shingles over time.

What Is A Roof Gauge

Gauge refers to thethickness of the metal panel and is represented in number form. Most metal roof and metal siding panels on the market are between 20- 29 gauge, with 20-gauge being the thickest and 29-gauge being the thinnest panels sold. These numbers refer to the and they have a range. For Example, 26 gauge could be a steel as light as .0179 or as heavy as .0217.

Don’t Miss: Does My Roof Need Replacing

How To Calculate Linear Feet

Step 1 – For each plane of the roof, determine the linear feet by calculating the width of the plane.

Step 2 – Add an overhang of six inches for each plane.

Step 3 – If you have multiple planes, add the measurements for each plane to calculate the total linear width of the entire roof.

Step 4 – For each plane, measure the length and add three inches for the sides of the roof. If you have multiple planes, add these totals together.

Step 5 – Multiply the total width by the total length for the total roof area.

Step 6 – Divide the total roof area by the width of the metal roofing material you intend to use. This will determine the amount of roofing material you need.

Benefits Of Standing Seam Metal Roofing

Compared to other panel profiles, a standing seam metal roof has quite a few benefits. Here are just a few:

- Aesthetics: The sleek lines and crisp, seamless look of the panels make them highly attractive to anyone looking for high-end or modern looking finished roof.

- High-Performance: Standing Seam panels are typically tested heavily against extreme weather conditions, like high-speed winds or heavy hail, and come out performing wonderfully.

- Fastener System: The hidden fastener system used in Standing Seam metal roofing eliminates most issues related to faulty, improperly installed, or rusting fasteners, which can occur with exposed fastener systems.

- Longevity: Like the majority of metal roofing options, Standing Seam roofs have an average lifetime of 40-70 years, compared to other materials like shingles, which typically only last between 10-20 years.

- Durability: Just like other metal roofs, Standing Seams durability is a huge advantage it stands up extremely well in all different types of environments with ease.

Read Also: Can You Mount Solar Panels On A Metal Roof

Tile Form Roof Sheet Size

Tile Form sheets are designed differently from the other sheets mentioned above, producing an authentic pantile effect across the roof.

The sheet width is the same as the other roofing sheets, measuring at 1000mm. The thickness, pitch and lengths are however different to the other sheets – to help improve the structural integrity and installation process, whilst keeping them low-maintenance and high-quality.

Like Corrugated, these sheets feature a ‘wavy’ pattern that measures 41mm from the peak of one wave to the base of the sheet. With a 1000mm width coverage once installed and lapped sheet over sheet, the measurement of Tile Form is 1000mm across.

Tile Form sheeting is available in lengths of up to 5 metres, which reduces the overall weight per sheet. The thickness of Tile Form is set at 0.6mm, instead of 0.7mm as with the thickness of Corrugated and Box Profile sheets. This helps to reduce the weight of each sheet and the overall downward pressure of the roof once installed.

Should Be No Exposed Fasteners

One of the most significant benefits of standing seam metal roofing is that no fasteners are visible on the surface, which means they arent exposed to UV, moisture, wind, and other elements that can cause a fastener to wear or fail over time. Also, standing seam systems dont put holes in the panels that protect your structure. Some people see fastener heads as unsightly, so using a standing seam system to hide them is common.

Also Check: How To Tell If Your Roof Needs Replacing

Standing Seam And Corrugated Metal Roof

Standing seam metal roofs have been used predominantly on commercial buildings for many years, but recently they have gained popularity as a hip roof replacement system for residential homes.

Standing seam installations are covered by ASTM Specification A730/A730M for Installation of Metal Roof Deck, G90.7.31 Standard Practices for Installation of Standing Seam Metal Roof Systems, and G90.7.32 Standard Practices for Installation of Corrugated Metal Roof Panels.

Since 1938 the standing seam roof has been a staple on commercial buildings because of its durable nature, lasting 50 years or more with little or no maintenance needed to repair leaks.

Due to its simplicity and durability the standing seam roof has been used all over the world and is one of the most accepted metal roofs.

Corrugated metal sheets are commonly used on commercial buildings such as warehouses, big-box stores and car dealerships where aesthetics are not a high priority because corrugated panels add strength and give this type of structure its big rig appearance.

In recent years, corrugated metal roofing has been gaining acceptance as a residential roofing material because it is more affordable, environmentally friendly and has a more appealing look than other types of exterior cladding materials such as asphalt shingles or wood shakes.

Also Check: Roofing Costs In California

/1000 Tile Form Profile

Tile Form sheets are only recommended for roofing applications, and not for wall cladding, to achieve the look of traditional roof tiles. The pitch or angle at which these tiles should be installed is 12 degrees. This type of roofing sheet is available in a range of three colours: Copper Brown, Graphite Grey and Black.

The coating used for tile form roofing is called Prelaq Mica, which is a tougher steel coating with more thickness, that provides the roof with excellent protection from corrosion and harsh weather conditions. This makes it one of the longer-lasting sheets that require little in the way of maintenance throughout its lifespan, however Prelaq Mica is only available in 3 different colours when compared to other coatings.

Don’t Miss: Where To Buy Roofing Material

Buy Manufacturer Direct And Save Money On Your Metal Roofing Panels

We recommend that you get a quote from more than one company. You want a company that has great and a fair price. Our online form is quick and easy to fill out. Let us provide you a free quote.

When you buy metal roofing from Western States Metal Roofing you are purchasing directly from the manufacturer. Buying directly from the metal supplier can save you 15% to 50%. Our company offers inexpensive delivery throughout the entire country. Give us a chance to earn your trust and provide excellent customer service. Look at out our google reviews and give us a call at 877-787-5467.

Start the process of picking out your panels by requesting a quote.

Standing Seam Panel Profile Types

One of the most significant selling points of standing seam metal roofing is the variety of choices and options for customers. These choices stretch far beyond just the panels color to include the length, width, profile, shape, thickness, etc. One of these choices is the panel profile type.

A panel profile refers to the shape and way two or more panels are seamed together. Depending on what type of roof you have, how steep it is, what environment your property is in, and various other factors, it will dictate what profile you should pick with the help of a contractor or architect. Many panel profiles comprise the standing seam category, including snap-lock, mechanical seam, batten panel, and nail/fastener flange.

Recommended Reading: How To Choose A Roofer

How Far Should A Metal Roof Overhang The Drip Edge

To provide a drip edge, allow an overhang of 1 to 2 inches at the eave. At the gable edge, use a gable or sidewall flashing. This will keep weather out, prevent lifting in high winds, and provide a neat, finished appearance. The trim and roofing sheet should be fastened every 12 to 24 inches along the gable edge.

Standard Size Of Roofing Sheets

Whenever someone is looking to add metal roofing to their home, they are undoubtedly curious what size sheets metal roofing comes in. Its tough to say the exact size or length of the metal roofing panel because it differs from one panel to another depending on the metal, style, and manufacturers specifications.

Choosing shorter metal panels for your home may leave holes on your roof, which will be prone to leakages. They will not be energy-efficient and will not protect your house from harsh weather conditions.

On the other hand, if you choose metal panels that are too wide or too long, it will cost you more in labor and there will be wastage from some of the panels.

When looking at metal panels on the market, you will notice they come in different gauges like 22, 26, 24, and 29. The length and width also vary from one panel to another. You should know the precise measurements of your roof while purchasing metal panels. Knowing the correct measurements will allow you to choose the right size of metal panels for your home so that they cover your entire roof.

Don’t Miss: How Often To Replace Roof In Florida

Corrugated Roofing Sheets: Dimensions And Size

Corrugated sheeting is a popular choice for both domestic homes and industrial/agricultural applications due to its design. The ‘wavy’ design of the corrugated metal sheets provides efficient water run-off to reduce water pooling on top of the corrugated sheets in wet climates, helping to minimise maintenance and keep your roof cost-effective. They are also a popular choice for cladding the side of your build.

The recommended length for corrugated sheets is up to 6 metres. This is when choosing the corrugated metal thickness of 0.7mm. If you’re planning to use the roofing materials for steel cladding, then sheet length runs go up to a maximum of 5 metres. For wall cladding applications, it is recommended to use a sheet gauge of 0.5mm for corrugated roof sheets.

The width of Corrugated roof sheets provides 990mm horizontal coverage when lapped by one corrugation, which is the desired amount for corrugated roofing sheets. Bear this in mind when measuring and ordering roofing sheets, as this will affect the number of runs you’ll need to secure.

How Long Are Metal Roof Panels

Roofing systems composed of steel and metal include thin, lightweight flat roofs and pitched roofs. Metal roofing is available in 24 inches width and 36 inches width.

However, because there is a 2-inch overlap on both sides for each of these widths, its the ideal complement to the existing range. You may buy metal roofing in whatever length you want and have it cut to the right size before installing the metal roof panel.

In this regard, what size are metal rooftop panels? The steel panels are available in 18, 20, 22, and 24 gauge widths with widths of 27 to 46 inches. The panel in 48 inches can reach up to 12, 10, and 8 feet long, while the panel that is 27 inch in width can be up to 20 feet long.

Second, how can you quantify metal roofing panels in terms of length and width?

The length of your roof is divided by the width of the metal. In our scenario, well utilize 24-inch standing seam roofing, so divide 360 by 24 to get 15. The number of metal panels required for one side of the roof is 15 in this case then.

Also Check: How Long Does It Take To Build A Roof

Two Types Of Standing Seam:

Field-locked standing seam requires special crimping tools to crimp down/lock the seams during the installation.

Snap-lock standing seam system is a bit pricier, but the seams can be locked by a simple snapping of the panels together.

Regardless of the type of system you choose to install, you will have to use manufacturer approved fasteners with every panel during the installation.

What Is Thicker: 24

When it comes to 24 vs. 26, 24-gauge is the thicker metal. Measuring gauge metal panels can be confusing because the lower the number is, the thicker the metal is. For our recommendation about which thickness would work best with your building, please feel free to contact us at any time to schedule an appointment with one of our techs.

You May Like: Does A New Roof Lower Home Insurance

Wider Metal Panel Widths

Standing seam panels typically come in ranges from 12 to 24 wide. Wider panels are typically more cost effective for a couple of reasons. First, they generally cost less to purchase from the manufacturer. The lower cost comes in part from personnel at the manufacturing facility physically producing less panels to cover the same square footage. There are also some freight advantages with wider width panels as there is less crating and packaging involved to cover the same roof plane.

But the bigger benefit comes in the form of labor and accessory savings. As you might imagine, a contractor can install 1-24 wide panel much more quickly than he can install 2-12 wide panels to cover the same space on the roof. In this example, in addition to handling more panels, the installer would also have the additional cost to purchase and install twice as many clips to attach the narrower panel to the substrate than he would the wider panel option. Labor and materials arent necessarily cut in half for the wider panel but the savings are significant.

Standing Seam Roof Guide Part : Panel Design

If you are tired of re-roofing your home and want to do it for one last time, you are most likely considering a Metal Roof. After all, they do last a lifetime, and standing seam is the most common and economical form of metal roofing used in Texas and the rest of the United States. Itâs a great roof style for Texas, that is popular in San Antonio, Hill Country, Coastal Bend, and The South Texas Valley.

Read Also: Can A Roof Be Installed In The Rain