How To Calculate Metal Roof Cost Metal Roof Formulas

Although our metal roof calculator will do all the work for you, we understand that you may feel more confident if you know how to carry out the calculations yourself. Here are detailed instructions on how to calculate metal roof cost on your own.

- calculating roof area based on roof measurements: roof length * roof width = roof area

- calculating roof area based on footprint measurements: footprint length * footprint width * roof pitch multiplier = roof area

- calculating panel area: panel length * panel width = single panel area

- calculating number of panels to buy: roof area / panel area = panels needed

- calculating the cost of buying the panels: cost of a single panel * number of panels = total expenses

What Is Thicker: 24

When it comes to 24 vs. 26, 24-gauge is the thicker metal. Measuring gauge metal panels can be confusing because the lower the number is, the thicker the metal is. For our recommendation about which thickness would work best with your building, please feel free to contact us at any time to schedule an appointment with one of our techs.

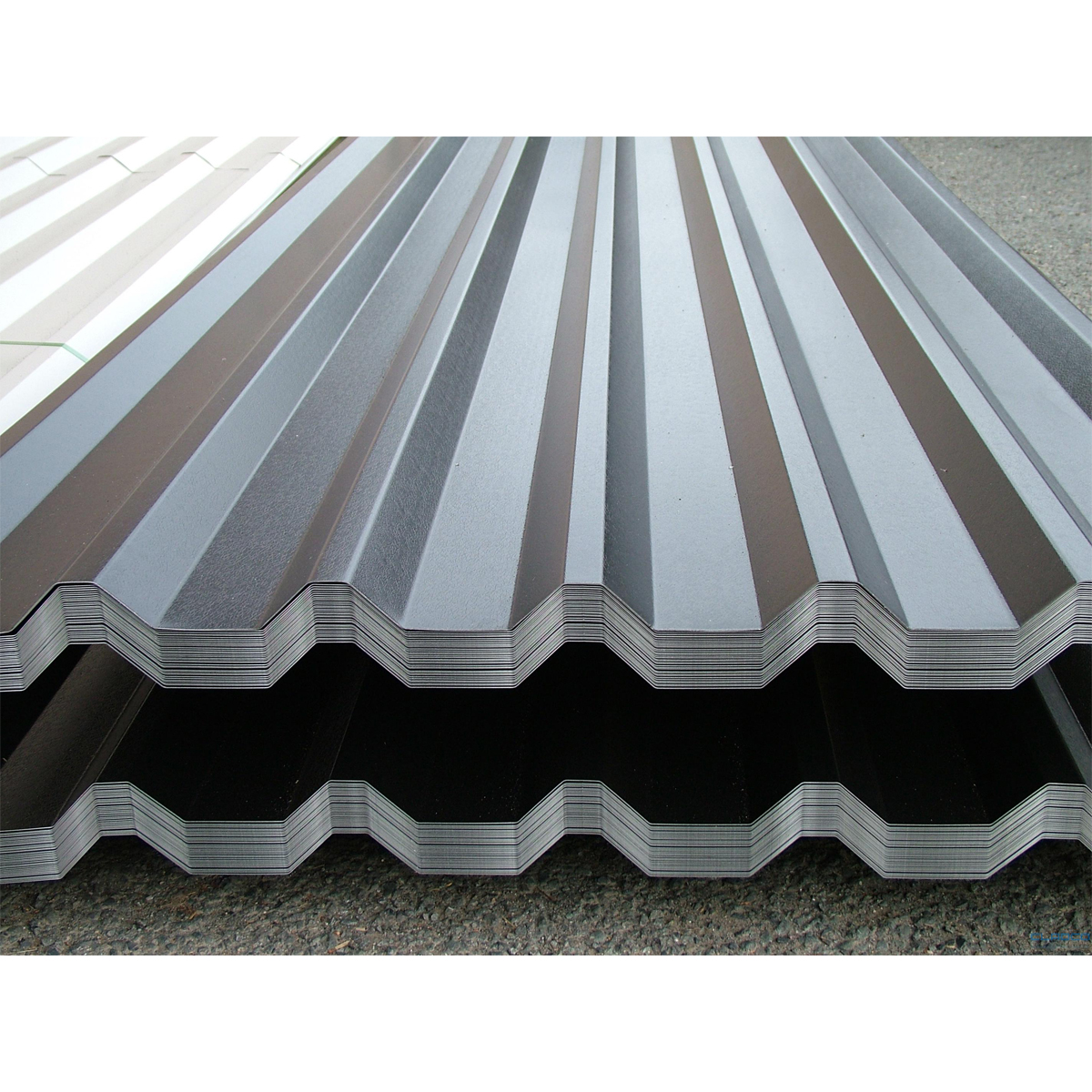

/1000 Box Profile Sheeting

How wide are steel roofing sheets? The 32/1000 Box Profile design measures 32mm in height with a 1000mm width coverage. When compared to the 34/1000 Box Profile, the 32/1000 steel sheets have a slightly shallower profile cross-section, giving it a robust design and a less obtrusive overall appearance once installed on a roof due to the fewer profiles. Despite their different heights, the 32/1000 and 34/1000 metal roofing sheet sizes cover the same width of 1000mm.

Box Profile Sheeting can be purchased in a wide range of lengths to suit your roof. The maximum length for Box Profile sheeting is 9 metres when choosing 0.7mm sheets, and 7-metre lengths when choosing the 0.5mm sheet thicknesses.

The gauge or thickness, usually 0.5mm and 0.7mm, will change not only the weight of the sheets but also the durability. Thinner sheets are usually applied to wall cladding applications, whereas 0.7mm is recommended for roofs.

Sheets are available in a wide range of coatings and colours, from Polyester to PVC Plastisol, or just plain galvanised. If you’re working out the length and width of your roof materials, it’s advisable to include some extra for wastage, between 5% and 10%.

Also Check: How Much Does It Cost To Replace A Slate Roof

Tile Effect Metal Roof Sheets

Designed to imitate clay and concrete tiles, tile effect roofing sheets combine the durability of steel with a traditional aesthetic. You have a choice of profiles, such as the classic pantile.

Each of the different styles is then coated with granules, achieving a more realistic finish and added durability. These panels are ideal if youre looking to match the appearance of an adjacent building.

Standard Size Of Roofing Sheets

Whenever someone is looking to add metal roofing to their home, they are undoubtedly curious what size sheets metal roofing comes in. Its tough to say the exact size or length of the metal roofing panel because it differs from one panel to another depending on the metal, style, and manufacturers specifications.

Choosing shorter metal panels for your home may leave holes on your roof, which will be prone to leakages. They will not be energy-efficient and will not protect your house from harsh weather conditions.

On the other hand, if you choose metal panels that are too wide or too long, it will cost you more in labor and there will be wastage from some of the panels.

When looking at metal panels on the market, you will notice they come in different gauges like 22, 26, 24, and 29. The length and width also vary from one panel to another. You should know the precise measurements of your roof while purchasing metal panels. Knowing the correct measurements will allow you to choose the right size of metal panels for your home so that they cover your entire roof.

Recommended Reading: How Do You Know When To Replace Roof

Trim For Corrugated Metal

If youre learning about how to screw down a metal roof then theres a good chance you will need help installing the corrugated metal trim or the corrugated metal panels. Our easy to navigate Metal Roofing Learning Center has step by step installation videos for all of your corrugated trim installation details.

Disadvantages Of Aluminum For Roofing

- More Prone To Denting

- Less Availability and Color Options

More Prone To Denting

Aluminum is a softer metal when compared to steel. Aluminum is more prone to dents from hail and the weight of falling branches or debris.

Using heavier thickness aluminum will help increase resistance to dents, strength, and durability, but will also cost you more. As you might expect, the heavier the aluminum, the higher the price.

Where To Buy Aluminum Roofing

Aluminum roofing is harder to purchase than metal roofing. There are fewer manufacturers and suppliers that offer this type of metal. Its not that its exceptionally difficult to purchase, but you will definitely have fewer options. Especially in areas that are not located along the coast.

The lack of availability will also affect the price of aluminum roofing. Its likely that even if you find a supplier that can get you aluminum roofing, they will have to ship the material in from a different location. This will further increase your costs.

Aluminum Roofing Colors

Because there is less demand for aluminum vs metal, there will be fewer colors to choose from. As long as you want a very basic color it will be available. For example, if you want a specific shade of green you may have a problem. In aluminum, there may only be one or two green colors to choose from. Whereas that same green color for another roofing material would have four or six different color choices.

Aluminum Roofing Has A Higher Cost

Recommended Reading: What To Put On Roof To Prevent Moss

Corrugated Roofing Sheets: Dimensions And Size

Corrugated sheeting is a popular choice for both domestic homes and industrial/agricultural applications due to its design. The ‘wavy’ design of the corrugated metal sheets provides efficient water run-off to reduce water pooling on top of the corrugated sheets in wet climates, helping to minimise maintenance and keep your roof cost-effective. They are also a popular choice for cladding the side of your build.

The recommended length for corrugated sheets is up to 6 metres. This is when choosing the corrugated metal thickness of 0.7mm. If you’re planning to use the roofing materials for steel cladding, then sheet length runs go up to a maximum of 5 metres. For wall cladding applications, it is recommended to use a sheet gauge of 0.5mm for corrugated roof sheets.

The width of Corrugated roof sheets provides 990mm horizontal coverage when lapped by one corrugation, which is the desired amount for corrugated roofing sheets. Bear this in mind when measuring and ordering roofing sheets, as this will affect the number of runs you’ll need to secure.

Nail Flange Or Fastener Flange Profiles

Nail flange is similar to a snap-lock panel system, but instead of using a clip to attach the panel to the roof deck, its directly fastened down to the deck through the male leg of the metal panel. Once the fasteners are in place, the female leg of the panel snaps over the entirety of the male leg, which hides the fastener head.

Nail Flange & Fastener Flange Quick Facts:

- Nail flange systems count solely on the head of the fastener to keep the panels attached to the deck, which could lead to problems in the future.

- Nail flange systems are a popular choice for residential applications because it tends to be the cheapest option for standing seam due to fewer required accessories for installation.

- Fastener/nail flange metal roofs are not the best performing systems and often lack engineering. Plus, they:

- Follow the imperfections of the roof deck

- Dont always accept roof clamps for snow retention or solar panels

- Cannot go on low-slope applications

- Are pinned, thus limiting expansion and contraction

- Can be difficult to snap together

- Can distort over time if formed in a rollformer where the drive and forming rollers arent separate

Read Also: How To Choose Roof Color

How To Choose The Right Metal For Your Roof

As you can see, there are a lot of options when it comes to metal roofing. To help narrow down your choices, we recommend considering the following:

- What is your roof budget?

Metal roofing materials come in a very wide price range. If you are looking to be as cost-effective as possible, then a corrugated metal roof is an affordable solution. On the other hand, if cost is not a concern, consider a copper or zinc standing seam roofing.

- What is your desired roof appearance?

Each material we discussed has its own unique look and style. Which one is best for you depends on your personal preference.

- How long do you want your roof to last?

If you are looking for a metal roof with a traditional look, metal shingles will blend in nicely with the rest of your neighborhood. If you are looking for a striking appearance, copper has a beautiful appearance that will stand out. If you are looking for a modern look, standing seam is very popular for its contemporary aesthetic.

- Is your roof near the coast?

You cant go wrong with any type of metal roofing when it comes to longevity. While they all have long life expectancies, installing a standing seam roof in zinc or copper roof can potentially last over a century. This will ensure that you never have to worry about installing another roof on your home again. However, even a corrugated metal roof can last up to 40 plus years.

- Do you plan on installing the roof yourself or hiring a professional?

/1000 Tile Form Profile

Tile Form sheets are only recommended for roofing applications, and not for wall cladding, to achieve the look of traditional roof tiles. The pitch or angle at which these tiles should be installed is 12 degrees. This type of roofing sheet is available in a range of three colours: Copper Brown, Graphite Grey and Black.

The coating used for tile form roofing is called Prelaq Mica, which is a tougher steel coating with more thickness, that provides the roof with excellent protection from corrosion and harsh weather conditions. This makes it one of the longer-lasting sheets that require little in the way of maintenance throughout its lifespan, however Prelaq Mica is only available in 3 different colours when compared to other coatings.

Read Also: Can You Have Gutters With A Metal Roof

How To Calculate The Width Of Corrugated Metal Roof

Since a corrugated metal roof is one of the cheapest and most widely used types of metal roofs, it can be easier to work out this metal roof types width. The simplicity and strength of corrugated metal sheets make them widely acceptable for roofing. It is also widely available and comes with low-cost maintenance. It is available in different thicknesses and sizes.

Your metal sheets must overlap during installation to provide a continuous and watertight finishing. With watertight finishing and no gap, water, wind, and other adverse weather elements will not penetrate. It also ensures structural integrity of the roofing.

The overlap of your roofing sheet must be taken into consideration when measuring the width of your roofing sheet. The first step is to measure the length and width of the area that requires roofing. You can get his measurement from the builders plan or stretch your tape along the roofs structural components to obtain the length and width.

Record your values on length and width measurement and then add measurements at the edges of overlap before rounding up the dimensions in feet measurement. If, for instance, you measure 21 by 10 as length and width of the entire area and an additional overlap of 6 x 1 in length and width are required at both ends, then your final measurements will be 26 x 11 in length and width respectively. Multiply the length and width measurement of the roof to get your surface area.

How Often You Screw Down A Metal Roof

Figuring out how the correct distance from screw line to screw line is an easy process. It will depend upon whether the metal roofing is installed over a solid wood substrate or over metal purlins. Each of these conditions will lead to different distances between the screw lines. After you have your screw line spacing it will be simple to determine how many screws to purchase.

Also Check: House Trusses Cost

Recommended Reading: How To Get Rid Of Mold On The Roof

Advantages Of Using Zinc For Roofing

Zinc Roofing Is Attractive

Zinc roofing panels have a striking aesthetic that makes them really stand out. Once zinc is exposed to moisture and carbon dioxide in the atmosphere, it will form a protective layer of zinc carbonate. The result from this process is a beautiful blue/gray patina.

Zinc Will Patina And Become Corrosion Resistant

Besides being beautiful, patina also serves a purpose in keeping the zinc from rusting. The protective layer that forms keeps the zinc roof from corroding. This makes zinc a great option to use as roofing if you live near the coastline as it will not be negatively impacted by the moisture in the air.

The Long Lifespan Of Zinc Roofing

A zinc roof will last 80-100 years or longer. Like copper, its a lifetime roof. Once you install it, you wont need to worry about installing another roof again.

Summary: Which Should You Choose

Choosing the right roofing materials for your building’s roof or cladding is going to be down to the look and colours you’re going for, whether that’s a traditional Box Profile design in Juniper Green colours, or a pantile effect in traditional Copper colours using Tile roofing sheets, as well as the installation specifications.

When it comes to side cladding, it is not recommended that you use Tile Form Sheets, and instead, stick to Corrugated sheets or Box Profile Sheets.

Thicknesses and colours of the sheets vary depending on the application, whether that’s for roofing or wall cladding, and bear in mind that coatings such as PVC Plastisol have a larger range of colours when compared to Polyester or Prelaq Mica coated sheets.

When calculating the width and number of roofing sheets for your roof, our online Roofing Calculator will be able to work out and filter down all the materials required for your build quickly, and provide a no-obligation quote. Please note, the final price provided by our Roofing Calculator does not provide delivery costs or delivery times.

Contact our sales team on for more information and advice on delivery and products when you are choosing roofing sheet sizes. Visit our Roofing Sheet Guide on our company website for further help, guidance and to see all colours available.

Newsletter

Also Check: Can Roofing Company Pay My Deductible

Corrugated Screw Location For Wall Panels Or Metal Siding

There will be five panel screws and one lap screw per screw line. The lap screw is the screw that sits in the high and it is designed for a light gauge metal to light gauge metal connection. Lap screws are spaced 12 to 18 on center. The panel screws are spaced out so that every third corrugation has a screw including both sides of the panel sidelap. When the corrugated sheeting is 39 wideinstead of 37 wide the screw placement will be slightly different as shown in the diagram below.

We recommend that you use double sided mastic tapeat the panel sidelap for a wall condition also. The mastic tape will make the panel more weathertight. Mastic tape is always used for a metal roofing installation. On a wall application, mastic tape is shown in our installation guide and we do recommend that its used. The reality is many installers choose not to install the mastic tape for wall conditions.

How Do You Cut Metal Roof Sheets

Metal roofing sheets can be easily cut using both manual and powered tools. For an easy and short cut, we recommend using either tin snips or a nibbler. Alternatively, if you want a faster and longer cut, a circular saw will be more effective.

Whilst using any cutting method, you must always ensure that you are wearing the appropriate safety protection gear. This includes safety glasses, a dust mask, work gloves and sensible shoes/clothing. You should also be using a stable workbench with clamps.

If you want to avoid the time and hassle of cutting your own metal sheets, take a look at our high-quality range of made to measure roofing sheets instead. These are carefully cut to your bespoke size prior delivery so all you have to do is fit them on arrival. Quick and easy.

Recommended Reading: How To Get Rid Of Bats In Roof

Can Be Harder To Repair Or Replace

If damage or another issue occurs with one panel or a smaller section of the roof, it can be tough to replace efficiently because each individual panel must be separated from the ones that are staying on the structure. This process can be especially tedious for mechanically seamed systems, as each panel will need un-seamed and any sealant will need to be broken through and removed.

What Is The Correct Screw Pattern And Spacing For R

The screw placement for R-Panelis straight forward. The screws are located in the same location for both metal roofing and metal siding applications. One item of importance is that you will have additional screws at the ends of the panels. This lessens the likelihood of strong winds ripping the panels off of your building.

There will be five panel screws and one lap screw per screw line at the panel ends. The remaining interior panels will have three panel screws and one lap screw at each screw line. Pay close attention to the diagram above in which the top left is circled. This is blown up larger and shown in the diagram as detail AA. You must attach a panel screw in this exact location. In addition, there are lap screws that are connected at 12 to 18 on center and butyl tape seal, which is the same thing as mastic tape.

The screw placement for 7.2 Panel and Western Rib is simple. Panel screws are located in every panel low. There will be five panel screws and one lap screw per screw line. Lap screws are connected at 12 to 18 on center and butyl tape seal is used at the panel sidelap.

Don’t Miss: How To Calculate Roof Surface Area