How To Install Corrugated Metal Roofing

- Written by Chris Nickson on Apr 19, 2010To ensure our content is always up-to-date with current information, best practices, and professional advice, articles are routinely reviewed by industry experts with years of hands-on experience.Reviewed by

Corrugated metal roofing has been around for a long time. Although you wont find it used on many houses these days, its still commonly used on sheds and garages. Corrugated metal roofing is easy to install but you should make sure you have help when fitting it.

Determine How Much

Before you start to install corrugated metal roofing, you need to figure out how much you need. Measure the length of the roof and the breadth of one side. Multiply those numbers and then double the result for the square footage of your roof. Corrugated metal roofing generally comes in sheets that are 3×6-feet in size . Divide the square footage of your roof by 18 to give you the number of sheets youll need.

Lay Tar Paper

As long as the wood on your roof is in good condition, you can go ahead and put tar paper down. Even if theres older tar paper in place, you should simply rip it off and replace it. Make sure the rolls overlap by at least four inches and staple them into place on the wood. This will help give you a moisture barrier on the roof.

Fit The First Sheet

Get help to lay the first sheet onto the roof. Be sure before you fasten the roofing itself, however, that you lay down closure strips underneath where the screws will go.

How To Install Corrugated Roofing

This article was co-authored by . Mark Spelman is a General Contractor based in Austin, Texas. With over 30 years of construction experience, Mark specializes in constructing interiors, project management, and project estimation. He has been a construction professional since 1987.There are 7 references cited in this article, which can be found at the bottom of the page.wikiHow marks an article as reader-approved once it receives enough positive feedback. This article received 20 testimonials and 90% of readers who voted found it helpful, earning it our reader-approved status. This article has been viewed 964,730 times.

Corrugated roofing is a great way to top a garden shed, shop, or patio. It’s quick, easy, low cost, and you can do it yourself. You only need some basic tools and materials.

Best Roofing Material For Low Pitched Roof

The best roofing material for a low pitched roof depends on the slope of your roof. Assuming your roof is shallower than 4:12 and you want to use metal roofing, then the determining factor is just how shallow your roof is and the amount of money you are willing to pay.

For a roof that is only slightly shallower than 4:12, then your best bet is lapped, corrugated metal. The term lapped means that the sections of the roofing panel lap over one another on the edges. The fastener typically a 2 metal screw with a thick rubber washer screws from above through the overlapping edges of the panel, into the substrate beneath the metal panels.

The neoprene washer provides an excellent seal, and the self-tapping screws themselves make only a minimal intrusion in the metal, as the threads are fine. The washer seals the top of the hole, which is made through the part of the lap that is raised, not the valley. In that way, water will not pool on top of the screw holes but run down the sides of the lap.

If the sealant is not applied to the lapping metal panels, then the shallowest slope is 3:12. Some metal panels that lap require sealant between the seams, in addition to fasteners. If you opt to apply a metal roof sealant, such as a butyl sealant, between the laps, then your minimum slope is ½:12.

Read Also: How To Replace Asphalt Roof

Using The Wrong Substrate Or Underlayment

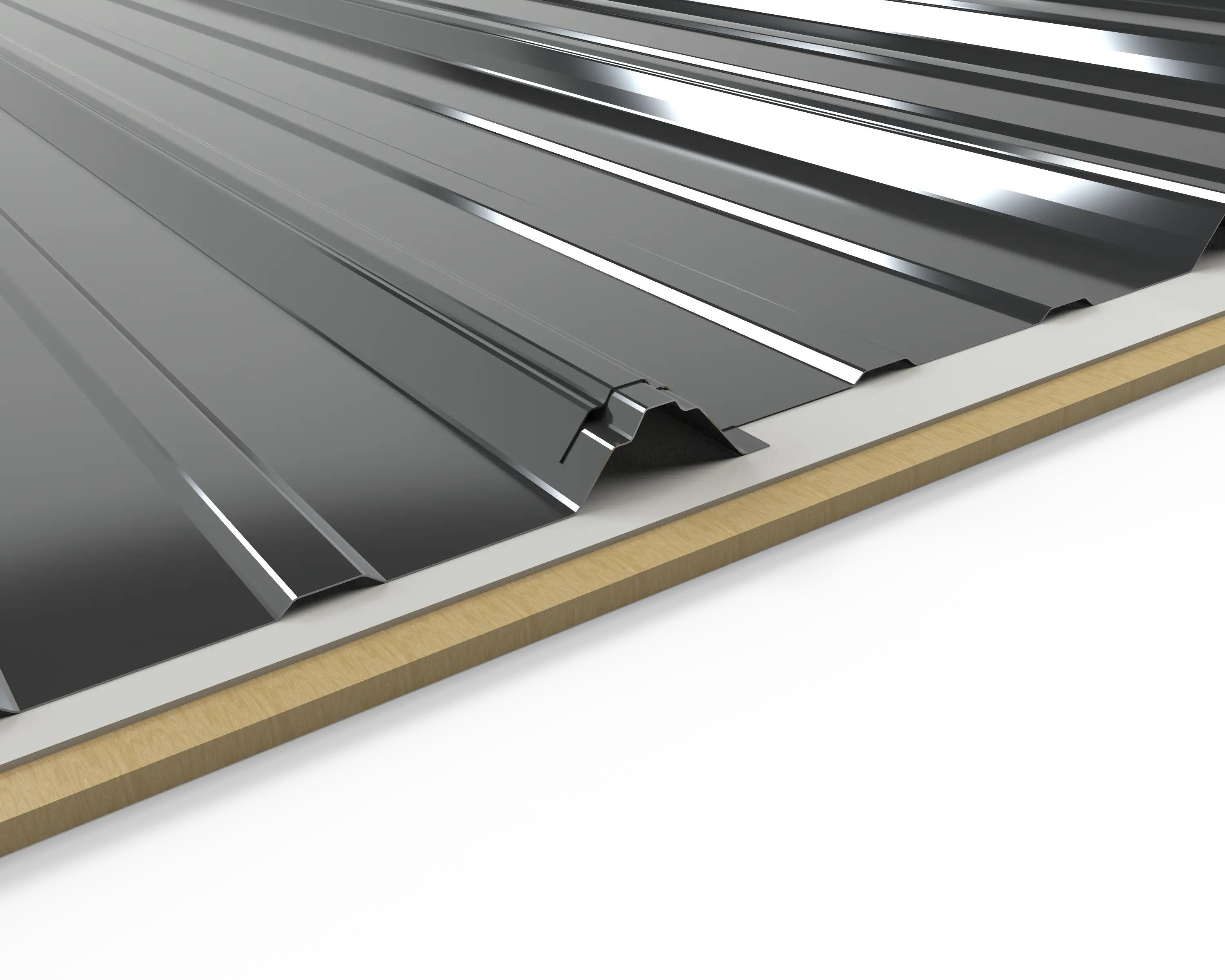

Metal roofing panels are usually designed to be installed over a solid substrate such as plywood. They can also sometimes be installed over battens rather than solid wood surfaces. As a general thumb rule, however, it is best to put them over a solid surface – particularly for smaller buildings like homes or garages.

Metal roof panels that are installed over battens are more likely to develop condensation behind the panels than those that are installed over solid surfaces. This is caused by the temperature difference between the cold metal panels and the warm, moist air that is trapped underneath them. To minimize problems with condensation, opt for a substrate such as plywood or OSB.

Even if you do install the panels over solid wood decking, you should still use an approved underlayment. This will provide additional protection against condensation, minimizing the likelihood of damage occurring.

Roofing An Enclosed Building

For enclosed buildings, you can apply roofing felt before adding the panels by stapling every 3 inches on the outside of the felt and about 5 to 7 inches on the interior. Foil-backed single bubble insulation can also be used under metal roofing. Foil-backed bubble insulation has an R-value of approx. 9.2 and blocks 97 percent of radiant heat energy.

Don’t Miss: How Much Does It Cost To Replace A Roof

Phase : How To Install Ridge Cap Vent For A Metal Roof

If you have a vented ridge cap it will require a ridge vent such as ProfileVent®. However, if you have a non vented ridge cap then you will want to skip this step and read the instructions above to install foam closure strips.

How To Install Your Roofing Sheets

This installation guide provides general advice on how to install a single skin sheeted metal roof. The advice within this installation guide is of a limited nature and should only be used as a guide. It’s not be relied upon as an exact instruction on how a roof should be safely installed which will vary with circumstances.

We have a skilled team of Customer Service advisors who will be happy to assist you with any installation queries you have, please feel free to call them on 01837 659 901. Cladco Profiles accepts no liability for any loss or injury caused by any reliance placed on this guide.

Don’t Miss: Can You Put A Skylight On A Flat Roof

Bend Trim Ends Closed

- Before you install the trim, cut and bend the leading end to wrap it around the corner. Make a series of one-inch cuts with aviation snips at each bend to create tabs. Fold the tabs in with a hand seamer to meet a wall or a corner, or to close a gap created by the trim. Each trim is a different shape, requiring unique cuts and bends.

- Install the eave trim tight to the fascia and fasten it to the roof deck over the underlayment with one-inch roofing nails. In warmer climates, the eave is attached before the underlayment. In northern Wisconsin, where ice dams are common, we install these atop the underlayment to protect the entire roof from dams.

Failing To Check With Your Insurance Company For Potential Problems Before Installing Your Roof

Insurance companies usually have certain requirements when it comes to the types of roofs that they will and won’t cover. For instance, did you know that some insurance companies won’t cover metal roofs that have been installed over existing shingles.

The best way to avoid any problems is by contacting your insurance agent to talk to them about the terms of your policy. That way, you can find out if there are any specific rules that you need to follow when it comes to choosing materials or installing your roof.

You May Like: What Is A Hip Roof

Install Drip Edges And Closure Strips

Begin installing drip edges along the eaves and rake of the roof. Use 1-¼-inch galvanized roofing nails to secure them and place the nails about 16 inches apart. If you need multiple runs of drip edges, lap them by 1/4 to 1/2 inch, and keep the nail back from the lapped joint. As you go along, pay attention to gutters. Drip flashing should overhang gutter lips by 1/2 an inch.

Add sealant tape along the drip edge and then peel back the backer paper of the closure strip to place it on top of the tape. Dont stretch out the closure strip.

Common Mistakes To Avoid When Installing A Metal Roof

When installed correctly, metal roofs are extremely durable. In fact, they are rated to last far longer than many other types of roofing materials, making them a great option for homes and businesses. Because metal is extremely durable, it does well in just about every climate, meaning that you can install one of these roofs regardless of where you live.

To ensure that your new roof doesn’t develop any leaks, however, it is important to install it correctly. This is especially true if you are installing the roof yourself rather than having a professional do it for you. Below is a list of some of the most common mistakes to avoid when installing a metal roof. Carefully read through this list before starting your roofing project so that you can keep from making any potentially costly errors.

You May Like: What Is The Average Life Of A Roof

Other Metal Roofing And Ridge Cap Types

The steps above explain steel roofing ridge cap installation for the most common metal roof and cap designs. There are other types as well, such as standing seam and shingle-style panels, vented ridge cap, skylight ridge cap, and formed ridge cap. Details of how to install these special types are given in the instructions that should come with them, and in other articles.

Can You Put A Metal Roof On A Low Pitch Roof

Yes, you can use metal roofing for low-pitched roofing. In fact, many contractors recommend that asphalt shingle roofs go no lower than 4:12 slopes, which doesnt leave you with too many options if your roof slope is any shallower than that.

Luckily, metal roof works extremely well in low slope applications. The most common type of metal roofing, and the cheapest, is a typical corrugated roofing with exposed fasteners. Metal panels overlap and the screws are placed through the laps to hold the sections together on the roof.

Some homeowners may cringe at the thought of exposed fasteners putting thousands of holes literally into your expensive roofing material, especially on a low slope. However, this type of roofing has been working for decades as leak-proof as shingle roofing and much more durable.

That standard type of metal roofing can go only slightly lower than a shingle roof, as the max depth for corrugated metal roofing sheets without sealant is 3:12. However, you can go lower without compromising your structure using metal roofing with sealant and other products, such as standing-seam click-lock panels.

Whichever product you choose, you are getting a metal roof that performs the same or better than a shingle roof. For low slope applications, your options for roofing materials are limited, and choosing a metal roofing product for these types of scenarios is a long-term, cost-effective choice.

You May Like: What Is Under Roof Shingles

Two: Cover Your Roof With Felt

The next step is to cover your roof. Purchase some standard roofing felt from your local home improvement store. Staple it onto your roof by inserting a staple every three inches on the edges of your room and every six inches in the space past the edges. Let deferent pieces of the felt overlap by at least three inches.

Which Way Does Metal Roofing Lap

metal roofinglappedshouldlaproof

. Hereof, how are metal roofs installed?

Metal roofing is also available in the form of shingles. Lay the starter row of metal shingles at the drip edge and affix to the roof with metal roofing nails. Most metal shingles will be attached to the roof using metal shingle clips, but metal roofing shingle installation can be system specific.

Additionally, what are the disadvantages of a metal roof? Disadvantages of metal roofs

- Affordability. Metal roofs can be as much as two or three times more expensive than other roofing materials.

- Noisiness. Metal roofs can be noisy, especially during a heavy rain or hailstorm.

- Expansion and contraction.

- Performance.

Likewise, can I overlap metal roof panels?

Metal roofs are lightweight, easy to install and much more fire resistant than asphalt shingles. The installation of metal roofing involves placing large metal panels on the roof. The panels overlap, allowing water to flow from one panel to the next without being able to penetrate the area under the roofing panel.

How much overlap do you need on a metal roof?

You can apply metal roofing to as low a pitch between 2 in 12 of rise and less than 4 in 12 of rise. This is called a low slope application and requires extra steps . – On an end lap ensure the panel above overlaps the lower panel. Use 3-6 of overlap at the end laps.

Don’t Miss: How Do You Measure Pitch On A Roof

How To Lay Corrugated Roof Sheets

For a single pitch roof the minimum pitch we recommend is 10 degrees. For a single run of sheets start at the eaves and in the corner away from the direction of the prevailing wind . If the first sheet is not laid perpendicular to the eaves and ridge, adjustments will have to be regularly made when laying other sheets and a saw tooth effect at the eaves will be seen. This may be unavoidable if the building is not square.

The first row of sheets should extend over the bottom purlin and the eaves so that rainwater can drain into a gutter or beyond the wall.

Sheets should be overlapped by the next sheet in the run by at least one profile or corrugation .

Please note maximum length of sheet we can supply is up to 5m in 0.5mm thickness and 6m in 0.7mm thickness. If you require a longer length, you will need to do a 2-sheet run as above.

You should always overlap the sheets by at least one corrugation. When overlapping sheets its recommended to use mastic lapping tape.

For side laps. It is good practice to use mastic lapping tape and stitching screws to ensure a robust weather resistant joint on side laps. Lapping tape with a section of 9mm x 1.5mm mastic should be run along the crest of the profile that is to be lapped, sheet to sheet stitching screws should then be used at 600mm intervals down the lap to consolidate the bond created by the lapping tape.

Complete The First Row

When itâs time to lay another metal panel, overlap the previous piece by at least one rounded corrugation. This will help to weatherproof the roof. Drive screws into the overlapped edge and bottom of each successive sheet.

For the last panel of every row, you may need to cut it to size, keeping in mind the need for overlap. You can use a saw or tin snips for this.

Don’t Miss: How To File A Roof Claim

How Much Should A Corrugated Roof Overlap

The upper sheet should overlap the first by 6 inches. Fasten the sheet and complete the second row in the same manner as the first. Each sheet should overlap both the sheet below it and the sheet to the side.

Thereof, Can you paint corrugated plastic roofing?

To begin, corrugated plastic roofing does not handle extreme heat as well as corrugated metal. It is also an option to paint the plastic panels, but this requires a special kind of paint. Lastly, corrugated plastic roofing is also thought to be more water-tight than metal which could be a great benefit in wet climates.

Also to know is, How long does corrugated plastic roofing last? When corrugated plastic is used indoors, it can last anywhere from 5 years to more than 20 years, depending on conditions.

Subsequently, question is, How do you fix corrugated roof sheets?

Also, How much overlap do you need on a metal roof?

Align the first metal roofing panel so that it overlaps the edging by 1/2 to 3/4 of an inch and is square to the roof line. Be sure the larger edge is laid so that the small edge of the next panel will overlap it.

Drive Screws Just Right

- Fastening the panels just right is the key to a watertight roof. Here is what you should know:

- At the eave, place screws on both sides of every rib and lined up to go through the foam closure strip.

- Each row should be spaced no more than 24 inches with one screw at each rib on the overlapping side.

- Start at the bottom, fastening across the panel in rows, working toward the ridge.

- Drive screws to seat flat on the roof a crooked screw wont seal.

- Dont over-tighten or under-tighten. Tighten just enough to compress the rubber gasket to the edge of the screw head, not past it.

- Clean up any metal shavings or burrs right away. They will rust.

Also Check: Does House Insurance Cover Roof Leaks

Laying Box Profile Roof Sheets

For a single pitch roof the minimum pitch we recommend is 4-5º. Lay Box Profile sheets in runs. Start at the eaves and in the corner away from the direction of the prevailing wind . If the first sheet is not laid perpendicular to the eaves and ridge, adjustments will have to be regularly made when laying other sheets and a saw tooth effect at the eaves will be seen. This may be unavoidable if the building is not square.

The first row of sheets should extend over the bottom purlin and the eaves so that rainwater can drain into a gutter or beyond the wall.

Sheets should be overlapped by the next sheet in the run by at least one profile or corrugation .

Please note maximum length of sheet we can supply is up to 9m. If you require a longer length, you will need to do a 2-sheet run as per image above.

You should always overlap the sheets by at least one corrugation. When overlapping sheets its recommended to use mastic lapping tape.

For side laps. It is good practice to use mastic lapping tape and stitching screws to ensure a robust weather resistant joint on side laps. Lapping tape with a section of 9mm x 1.5mm mastic should be run along the crest of the profile that is to be lapped, sheet to sheet stitching screws should then be used at 600mm intervals down the lap to consolidate the bond created by the lapping tape.