Whats Better For Roofing: Osb Or Plywood

OSB is the better option for roof decking because it is cheaper and comes in a wider variety of larger sizes than plywood. Strand board does not react as well to moisture as plywood does, but it will have a more consistent thickness and fewer weak spots like knots than plywood.

If you are concerned about moisture getting into your sheathing, then plywood may be a better option. Plywood dries much faster than OSB because it is not as dense. There are usually only several layers of plywood per sheet while there are up to 50 layers of wood chips in a sheet of strand board, plus much more adhesive than a sheet of ply.

Since there are so many layers in OSB it is somewhat heavier than plywood. It takes water longer to penetrate it, but once it gets into the sheet then it takes a much longer time to dry. A board that stays wet longer is prone to sagging, which is why strand board tends to sag over time on many homes.

Finally, if you are going to sheath a shed that isnt heated, then OSB would definitely be a better option, provided you install the roofing material properly. There wont be any condensation issues, so your roof deck is liable to stay dry. In that case, strand board is best instead of plywood.

What Does Osb Board Look Like

OSB board is a type of engineered wood that is made from pieces of wood that are glued and pressed together. The wood used to make OSB board is typically wood that is not suitable for making furniture or lumber because it is not strong enough or it has knots in it. The wood is cut into small pieces and then glued together with resin. The boards are then pressed together under high pressure and left to cure.

What Else Can You Do With Osb

You could easily create all your furniture using OSB! The natural finish looks perfect married with white and has been used to create desks, tables, sofas and cupboards. Theres also a growing number of artists that use OSB as a canvas because of its great texture, it gives a unique finish with the layers of wood showing through. Heres an example from the fantastic artist Coraline VB who has an Etsy shop at DessinsDeCoco.

Dont Miss: How To Add A Gable Overhang

Read Also: How Do I Measure My Roof For Shingles

Contact Licensed Professionals For Installation Assistance

Installing roof decking is not an overly-complicated task. Still, its one that should be done right if you want to ensure your roofs maximum longevity.

You should nail very carefully and make sure you always stagger the vertical seams. You also need to be careful not to overload the top at the points where the decking is weakest.

If all of this sounds overwhelming or too risky to do on your own, its always best to reach out to licensed and experienced professionals to give you a helping hand. Code Engineered Systems has been a trusted residential and commercial roofing contractor since 2004. Our roofing expertise is the best in the region.

If you need help installing roof decking or choosing the most suitable roof sheathing thickness for your roof, reach out to us today. Call 813-373-9088 to get a free roof estimate for your project. You can also fill out our quick online form, and well get back to you without delay.

One: Determine The Square Footage Of Your Roof

The first step in determining the size of the OSB board you need is to determine the square footage of your roof. To do this, you will need to measure the length and width of your roof. Once you have these measurements, you will need to multiply them together to get the square footage. For example, if your roof is 10 feet long and 20 feet wide, the square footage would be 200.

You May Like: What Is Hail Damage On A Roof

The Sheathing On Older Homes May Have Been Attached With Nails That Are Too Small Or The Sheathing May Simply Need Shoring Up Due To Routine Wear And Tear Learn How To Weather Any Storm By Strengthening The Roof Sheathing In Your Home

By Bob Vila | Updated Jun 23, 2021 10:18 AM

We may earn revenue from the products available on this page and participate in affiliate programs.

Many houses contain a weak link in the connection of the roof sheathing to the rafters or roof trusses, making them vulnerable to loss of roof sheathing in severe winds, but solutions to this problem are available to the homeowner.

The problem exists because nail sizes and spacing used to attach the sheathing to the roofs structural members do not provide enough strength to keep the sheathing on during an intense windstorm. Before Hurricane Andrew devastated South Florida in 1992, roof sheathing was generally attached using 6d nails spaced at 6 inches along the edges of the sheathing and at 12 inches along interior structural members.

Now, however, experts almost universally recommend using 8D common nails. Your roof will be more resistant to heavy winds if you use the right nails to secure the sheathing, according to James Bedford of Fort Collins Roofing in Fort Collins, Colo. 8D nails are about 2 1/2 inches long and 131/1000 inch in diameter, he adds.

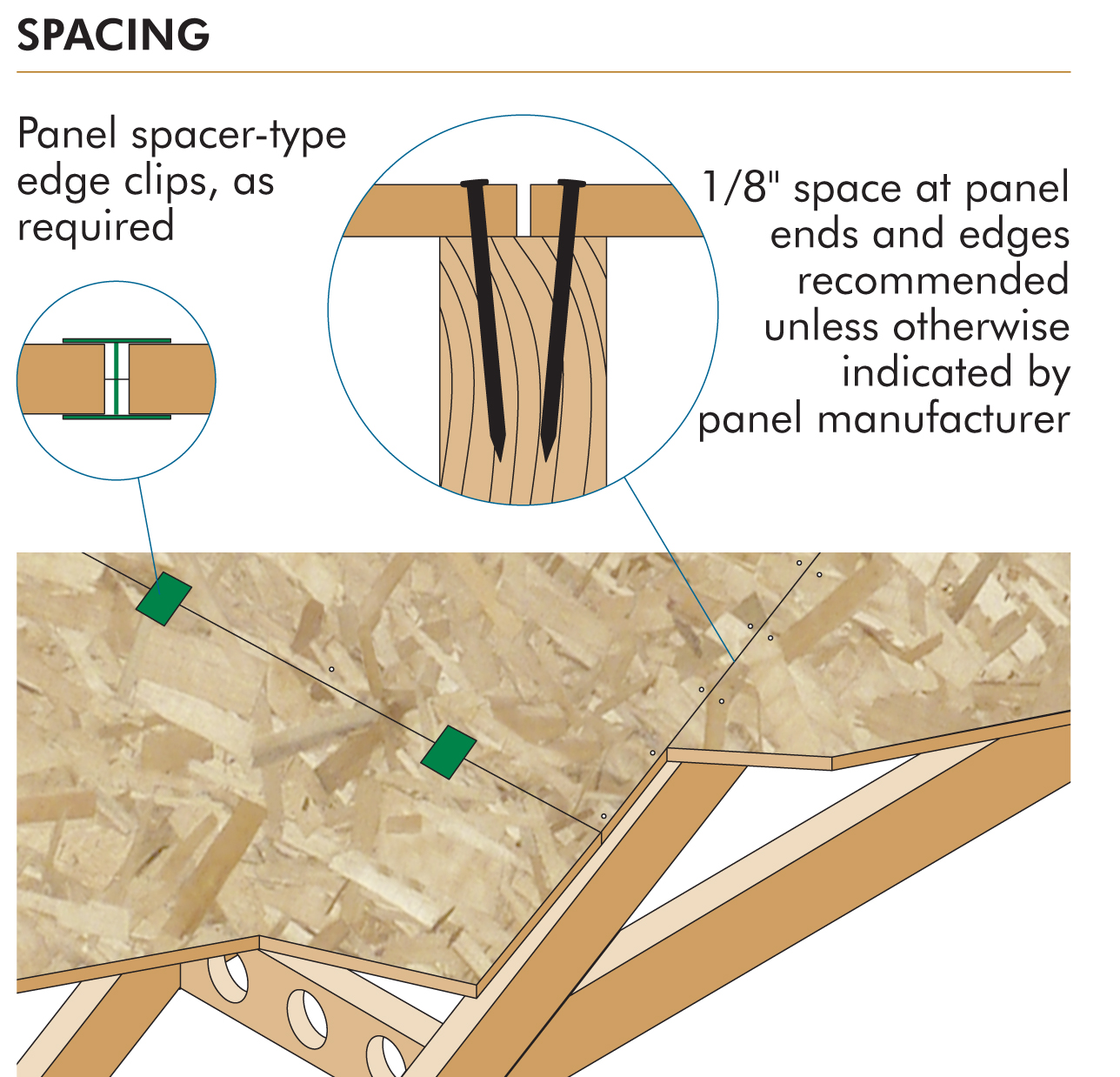

The nails should be placed no more than 6 inches apart and fastened 3/8 inch from the sheathing panel ends and edges, says Nora Robinson of B& M Roofing in Long Beach, Miss. And if you live in a particularly windy area, a few extra nails must be used for added support, adds to home remodeler Joseph Scaduto.

What Kind Of Nails Do You Use For Sheathing

nails

Using proper nails to attach sheathing will help your roof withstand strong winds. Traditional sheathing material typically comprises 15/32-inch plywood or oriented-strand-board panels. Builders generally use 8d common nails, which are approximately 2 ½ inches long and 131/1000 inch wide in diameter.

One may also ask, should roofing nails go through the sheathing? A 1nail will fully penetrate through 3/8roof sheathing, but it wont fully penetrate 1/2sheathing. The other way to determine if the proper nails were used is to look in the attic if the roof has 1/2sheathing, you should be able to see the nails sticking through in to the attic.

Considering this, what kind of nails do you use for plywood?

Framing nails are used for plywood assembly both interior or exterior. They are referred to as sinker nails, common nails and box nails. Sinker nails have a waffled head, which makes driving them easier, and a coating over the shank to keep them solidly in place once driven.

Can I use screws for roof sheathing?

Screws can be used for even greater withdrawal strength, but should be sized by the building designer. Staples are not recommended for roof sheathing attachment in high-wind areas.

Also Check: Maximum Metal Roof Overhang Without Support

You May Like: What Do Roof Inspectors Look For

Plywood Holds The Moisture Advantage Over Osb

However, there is one area of concern in which plywood beats OSB. The biggest difference is how both react when exposed to large amounts of moisture over an extended period of time. Except on projects in very dry regions, , sheathing is often exposed to rain, snow, and ice during construction delays. When plywood gets wet, it tends to swell. However, it does so consistently across the sheet, and returns to normal dimensions as it dries out. Because Plywood dries out relatively quickly, the swelling is usually not enough to affect roof finishes. In this case, plywood has the edge.

OSB takes longer than plywood to get saturated, but also takes much longer to dry out. When used as roof sheathing, this tendency to hold moisture means it will degrade faster than plywood when exposed to chronic leaks. Furthermore, when OSB gets wet, its edges tend to swell and stay swollen even after the panel has dried out. Swollen edges have been known to display as visible ridges called âghost linesâ through asphalt roof shingles. OSB manufacturers developed water-resistant edge seals to correct the problem, but the edge seal gets lost as panels frequently get cut on-site.

How Many Sheets Of Plywood Do You Need For A Roof

You can customize the plywood sheets if you want to purchase them in bulk. But your roof area is specific.

And the specified area needs a specific distribution of plywood. Lets assume your roof area is about 2400 square feet. And if you buy a 4 by 8 feet plywood sheet, it will cover 32 square feet of your roof.

Then if you do some quick math by dividing 2400 square feet of an area by the sheet area of 32 square feet, you get the number of sheets you need, which is 75 plywood sheets for your 2400 square feet roof area.

So, as per your roof area, you can get the number of plywood sheets you need.

Also Check: How To Remove Asbestos Roof

How Many Square Feet Of Roof Shingles Do You Need

A square of shingles is the number of shingles needed to cover 100 sq feet of roof area. However, shingles are packaged in a way that they are light enough for the average person to carry around. As a rule of thumb, there are 3 bundles to a square, assuming that you are using three-tab strip shingles.

How do you find out how much plywood you need for a roof?

To find the amount of plywood needed to cover a roof start by finding the area of the roof. Once the area is known, divide by the area of a 4×8 sheet to find how much sheathing is needed.

Is Osb Or Plywood Better For Roof Sheathing

Plywood Holds the Moisture Advantage Over OSB

When plywood gets wet, it tends to swell. OSB takes longer than plywood to get saturated, but also takes much longer to dry out. When used as roof sheathing, this tendency to hold moisture means it will degrade faster than plywood when exposed to chronic leaks.

Recommended Reading: What Is A Class 4 Roof Shingle

Roof Decking Thickness: A Real

If you have a standard roof pitch with roof rafters set 16 apart, an excellent way to go about it would be to install a roof decking thats at least thick. Again, keep in mind that this is the minimal roof decking thickness recommended in such a situation.

If you have a roofing structure comprised of rafters that are 20 apart or even more, you should install at least ½ or plywood decking. For most US homes, the most common rafter spacing is 24. If you have such a roofing structure, plywood decking will do the job. Its sturdy enough to support most types of roofs.

What Size Osb Board Do You Use For Roofing

There are a few things to consider when choosing the size of the OSB board for roofing. The first is the span of the roof. The span is the distance between the supports, and the OSB board must be able to span that distance without sagging. The next is the slope of the roof. The steeper the slope, the less weight the OSB board must support. Finally, consider the load. The load is the weight of the materials that will be placed on top of the OSB board, such as shingles or tiles.

Also Check: How To Charge For Metal Roofing Installation

What Is Roof Sheathing And Why Is It Important

Roof sheathing is composed of hardwood or metal covering that provides a flat, uniform, and stable platform for nailing or screwing the roofing material. It also acts as an additional layer between your house and the external roof materials, preventing water from going inside your house.

Sheathing reinforces your roof by equally distributing any weight or load applied. Roof sheathing serves the purpose of strengthening your ceiling and preventing it from collapsing upon itself. It is often connected to your roofs seams and trusses to keep your shingle from sagging or bending due to the changing environment. Roof sheathing provides additional fire protection by making it much harder for fire to spread to the rooftop.

How Osb Board Is Made

To make OSB board, first, they take the wood and run them through a machine to peel off all of the bark and sapwood from each individual piece of lumber.

Then it gets cut into thin slices which will be glued together with resin glue, then pressed flat in giant presses that operate at high pressure and temperature.

Once the glue has set, then they take it out of the press to get measured and cut into specific sizes for your projects youre going to be working on.

You May Like: How To Find The Right Roofing Contractor

/8 Or 7/16 For Roof Sheathing

5/8-inch paneling is a better choice for roof sheathing than 7/16-inch paneling. This is because of the durability and structural integrity that this additional thickness will bring.

Although 7/16-inch paneling is considered the most common choice for roof sheathing, 5/8-inch roof sheathing is typically one of the best sizes to use when selecting roof sheathing.

However, 7/16 paneling is a bare minimum requirement and therefore increased thickness is suggested for heavier builds.

What Is The Best Thickness For Roof Sheathing

There are various opinions on this matter, but the most commonly touted thickness for roof sheathing on a shed is 5/8-inch thick. Anything less may result in eventual bowing or sagging between the rafters or trusses, especially if you are using OSB. Some people trust 1/2-inch of thickness for plywood, which is a little stronger than OSB.

The absolute minimum you can consider is a 3/8-inch thickness, but its certainly not recommended. In fact, this thickness will not satisfy building code requirements in most places.

If you live in an area prone to heavy snow, you may even want to use something thicker. Roof sheathing is not a place where you can afford to skimp. It will also allow you to replace broken or cracked shingles without worrying about having to replace part of the sheathing. Youll still have a solid place to attach the new shingles. You surely dont want to have to worry about your shed every time the weather forecast includes several inches of snow.

Recommended Reading: How Much Is A New Roof In Arizona

What Kind Of Fasteners Are Used For Roof Sheathing

Substrates are usually fastened using either nails or screws. Since they are responsible for holding the entire thing together, its always critical to choose the right type of nails depending on the thickness of the boards youre using.

Ideally, you should use 8d ring shank nails that are specifically designed for roofing. These nails are about 2.5 inches long, making them long enough to fasten just about any roof substrate regardless of its material or how thick it is.

As for screws, the size will depend more on the thickness of the panels. For example, if youre getting a panel that is 1/2 inch thick or less, a #10 roofing screws would do the trick because its about 3 times longer than the board.

If youre opting for a thicker roof substrate, you can go for #12 roofing screws, which are about 2 inches long.

Lastly, you should never try to fix your roof sheathing with staples, as theyre never durable enough to hold up the roof properly.

The Downside Of Using The Osb Board:

The biggest downside of using OSB boards is that they can be easily damaged if you dont use them properly.

If your project involves nailing, screwing, or stapling the board to another surface like framing studs, then its more likely for something called shear failure to happen which means that there wont be enough support and the board will end up breaking.

To avoid this from happening, youll need to make sure that your project is sturdy enough for a product like OSB boards which can be a bit flimsy if theyre not properly attached. If its going to be used as exterior sheathing or wall cladding then make sure there are enough fasteners, particularly near the edges.

You May Like: How To File A Claim For Roof Damage

What Size Osb For Roof

The most commonly used OSB size for roofing is 7/16-inch OSB. Its slightly smaller than 1/2-inch roof sheathing and considered the absolute minimum where rafters/trusses are spaced 24 O.C. However, you can use other OSB sizes depending on your location and how far apart you space trusses or rafters.

Minimum Roof Sheathing Thickness

Minimum sheathing requirements dictate that thick is the lowest you can go in terms of thickness.

What happens if your roof sheathing materials are too thin?

Wrong dimensions will lessen the integrity of the overall structure of your roof. Thin layers of roof covers are more prone to bend between the foundation, thus compromising the outer roof system. When additional weight is applied to a board, the panel will sink over time.

Read Also: How Much Is Roofing Sheet In Ghana

Thickness For Roofs In Cold Climates

When it comes to choosing a thickness for the solid decking to put atop your framing on your shed or home, one of the primary considerations should be the weather.

Snow load should factor into your decision in terms of how thick your strand board or plywood will be beneath your exterior shingles or metal roof.

As mentioned above, all types of roof sheathing comes with a label that indicates spacing allowed between framing members. Beneath those numbers are the maximum allowable live and dead loads that panel can support.

For areas with extreme snow, look for panels that have total loads of 50 psf pounds per square foot. While that might not sound like much weight, just know that youll multiply that number over the number of square feet on your roof.

Therefore if you have a total of 2000 square feet, then the total load spread out over your roof is multiplied times 50, which is 100,000 pounds. That is more than enough strength to keep the snow from falling into your structure.