Metal Roof Prices By Type

It is important to understand that metal roofing is a broad term covering a range of materials with a large disparity in price. Metal roofing will generally run you anywhere from $3.10 to $29.65 per square foot, depending on which kind of metal roof you choose to install.

There are more affordable metal roofing options, like steel panels, which usually cost you slightly less, as well as high-end materials, like copper roofing, which tend to average out on the pricier side. Note that new metal roof replacement costs could reach up to $88,000 or more to install on a standard-sized 3,000 square foot roof.

See our chart below of the most common metal roof types and the average costs to install each. Note that the average installation costs listed are based on a standard 3,000 square foot roof.

Copy of Metal Roofing Costs by Type| Popular Metal Roof Types |

|---|

Average Cost per sq. ft:

$2.20 – $12

Aluminum roofing shingles cost $2.20 to $4.05 per square foot on average, while aluminum roofing panels cost closer to $9 to $12 per square foot. For a standard 3,000 square foot roof, aluminum shingles would cost anywhere from $6,600 to $12,150 while aluminum roof panels would cost closer to $27,000 to $36,000. Though metal shingles are not as affordable as corrugated metal roofing panels, panels are a better deal overall.

40 years or more

This type of metal roof is also fire resistant and can withstand harsh climates like hurricanes and other severe weather conditions.

Manufacturer Specifications And Warranty

When installing a product that is going to last 50 years, how necessary is a warranty? Will you really be able to track someone down in 40 years, have them come to your house, assess the problem, and write you a check? Even if you do, after depreciation, that check would be about $12. So my advice is, buy the best product you can afford, install it properly, follow the manufacturers specifications, and, after about five years, pitch the warranty.

| Take extra care to make sure roof valleys look straight. Errors are easy to spot. |

Measure The Roof Valley

Measure each roof valley from the lower end to the upper end and multiply the result by two, which provides nailers for each side the valley. Count the number of penetrations, such as duct vents and pipe risers that go through the roof. Include 4 feet of stripping for each, which translates to 12-inch-long nailers at all sides of a penetration.

Obtain one-by-three framing lumber for the nailers based on your measurements and calculations. Include 1 pound of 8d framing nails for every 100 square feet of the roof.

You May Like: How To Get Your Roof Replaced By Insurance

Purchase All Of Your Materials And Tools

After youve measured your roof, the next step is to purchase all the materials and tools youll need for installation. Again, refer to our list of tools and materials above, but now you will know more accurately how many materials youll need to purchase based on your roofs measurements.

Metal Roofing Sheets: These are usually available in three lengths and can be purchased in either the sheet form or in pre-cut lengths.

Metal Roofing Shingles: They come with a variety of widths and have an option for round shapes used on steep pitches.

Galvanized Steel Frames: These frames are available in different sizes and are installed first to support the metal panels.

Work With Experience Professionals

Remember that with any roofing or re-roofing project, the materials are only as good as those who install it. We believe our metal roofing is the best on the market. But if incorrectly installed, it will still lead to the same leaks and damages common with other products.

Our crew has more than 20 years of experience installing metal roofs. We understand the little differences and nuances of metal roofing to ensure you and your roof gets the best results. Interested in pursuing metal roofing over your existing roofing system? Request a roof quote today and find out how we can help.

Don’t Miss: Can You Finance A Roof

How To Avoid Rot Under A Metal Roof

So will your roof require venting? That’s a really important question to ask. In this case we’re spraying eight inches of open-cell spray foam insulation in the roof deck typically with that kind of installation you won’t need to vent the roof because it’ll be all sealed up from that spray foam. However, we’re using a product called Techshield that has an aluminum face on the bottom which reflects all the radiant heat from the roof, and that needs a 1-inch airspace. So we have to put vent baffles up in the rafter bays to create some airspace and have that breathe. Essentially, we’re creating a vented roof. So we’ve got a vented soffit that’s gonna allow air to get in from the low end of this roof right down below and travel up the rafter bay through that 1-inch airspace and out the roof. If that moist air gets trapped inside of our roof framing, and it gets really cold outside, that moist air is gonna condense into little water droplets and where is it gonna go but rot our wood framing so we really have to make sure that we vent this roof.

See the full transcript here.

What Does Installation Involve

Before any installation, your roof will need to be checked for any major problems. Any major problems will have to be fixed before installing a metal roof over asphalt shingles. Such problems include:

- Rotted wood deck

- Cracked or broken shingles

Once these issues have been resolved, installation can begin. Each roofing contractor will have their own way of doing things. Talk with your contractor if you are concerned about their methods.

For this type of installation, a new underlayment will sometimes be installed before working on the metal roof. After this, the metal roof can be installed. Most often, furring strips will be used to secure the new roofing to the shingles.

Once the roofing is on, edging will be installed to bring it all together.

To learn more about our installation process for metal roofing, Tampa residents can contact Affordable Roofing Systems at 542 8462.

Don’t Miss: How Much Is Steel Roofing Per Square

Install Metal Roofing Panels

Start installing metal roofing by overlapping the edging by 1/2 to 3/4 of an inch and make sure its square to the roof line. Remember to lay the metal roofing so the small edge of the next panel will overlap the larger edge. Pay attention to the manufacturers guidelines for placing screws. If you live in an area that experiences hurricanes there might be additional building codes that you have to follow.

Begin at the eaves and work up. Secure screws as you work but avoid over tightening. Add silicone sealant on the underside of the short edge of the next panel to provide a watertight seal.Continue to add panels and cut panels where needed to fit. Tin snips or a circular saw will work to cut the metal roofing.

What Is Metal Roofing

Metal roofing, as the name suggests are made up of metals like, aluminum, copper, steel, tin, and zinc. They come in the form of corrugated metals, slate roofs, or tile roofs.

Having a metal sheet up on the roof can prove advantageous if you are looking for a long term investment because of its longer life span, sturdiness, low maintenance, and great return on investment. It is a one time investment which can last up to 50-80 years depending upon the metal type.

Also Check: How Much Is A New Roof In Miami

Zinc Metal Roofing Costs

Zinc metal roofs have been around for more than 150 years now. It is an easily foldable material which makes them quite famous for designing unique roofs. Since their foldable quality does not change their structural strength and durability, they are crack and erosion resistant and can withstand harsh climatic conditions as well.

Tear Down Old Roofing

You may need to rent a dumpster to haul away any waste from the disposal of your old roof and the installation of your new one. Begin at the peak of your roof and methodically work your way across and down.

If any nails are sticking up, either hammer them all the way in or dispose of them if you choose. Inspect your roof substrate as you go.

Once all of your construction debris is ready for disposal or is out of your way, you can begin setting up your workspace.

You May Like: Is My Dryer Vent On The Roof

Metal Roofing Can Work On Roofs With Low Slopes

It’s often believed that metal roofing is suitable only for roofs with a steep slope, but standing-seam metal roofing can work fine on gently pitched roofs. This type of roofing is installed in large sheets with seams that are raised and sealed tightly together to resist water. While some slope is necessary to ensure water run-off, most homes can accept metal roofing.

Gather Materials And Prepare The Work Site

After measuring the roof, decide on the type of metal roofing material you want and how youd like the panels cut. When ordering metal panels and trim, give yourself some room for error and order 10-15% more to allow for waste. Youll also need to gather all essential tools and other materials like weatherproof underlayment, power drills, sheet metal screws, claw hammers, and more.

Before starting, prepare the outer perimeter of the home for work. Place trash cans for waste around the house. Also, laying tarps or painters cloth on the yard below the roof makes for easier cleanup.

You May Like: How To Calculate The Cost Of A New Roof

Finish With Ridge Caps And Gutters

Lastly, you can finish by installing the ridge caps and gutters. Ridge caps are metal or plastic panels that run along the roofs uppermost edge to protect it from water damage. At the same time, a gutter is a system for directing runoff rainwater away from your homes foundation. These will be the finishing touches and give your new roof nice clean lines and no exposed seams or edges.

Drive Screws Just Right

- Fastening the panels just right is the key to a watertight roof. Here is what you should know:

- At the eave, place screws on both sides of every rib and lined up to go through the foam closure strip.

- Each row should be spaced no more than 24 inches with one screw at each rib on the overlapping side.

- Start at the bottom, fastening across the panel in rows, working toward the ridge.

- Drive screws to seat flat on the roof a crooked screw wont seal.

- Dont over-tighten or under-tighten. Tighten just enough to compress the rubber gasket to the edge of the screw head, not past it.

- Clean up any metal shavings or burrs right away. They will rust.

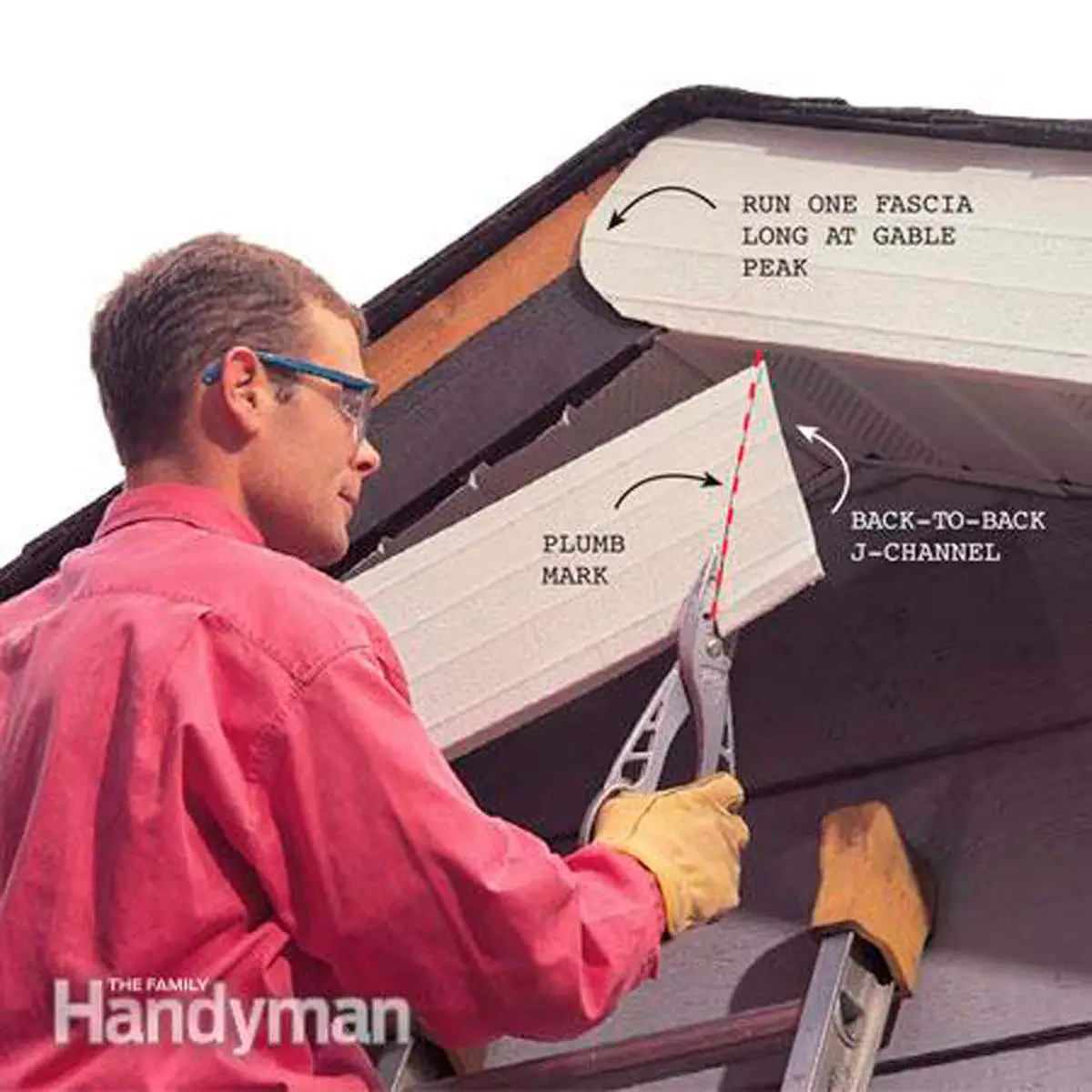

Family Handyman

Also Check: What Are Closure Strips For Metal Roofing

How Are The Metal Sheets Installed Over Shingles

Measure The Roof And Measure Again

Before you do anything, you must get accurate measurements of your roof. Youll need to know the square footage, the length of each section, and the width of panels youll need to order. Youll measure from the roofs ridge down to the eaves. Then measure the width and determine your square footage for each section of the roof.

Its easier when you have just two sides, but separate areas like over the garage or any dormers can complicate measurements, so keep that in mind. You can then order your materials based on square footage, plus add a few extras for mistakes or waste.

Read Also: How To Insulate An Aluminum Patio Roof

Average Cost Of A Tin Roof By Type Of Alloy

Terne roofs are made by chemically bonding tin to steel. Many types of steel are on the market, and two – standard and stainless – can create a tin roof. Because standard steel corrodes and is more difficult to work with, this terne roof is very difficult to find. Most manufacturers of terne roofing have switched to stainless steel, but a few still make traditional steel terne roofs. Stainless steel has a higher cost base, meaning a terne roof with a stainless steel core has a higher price. Below are the average costs per square foot for both materials.

| Alloy |

|---|

| $14.50 – $26 |

Tin Roof Replacement Labor Cost

Tin roofs are mostly found on older homes and historic homes that are being restored. This means when you have a new tin roof installed, you are likely removing an existing roof or roofing over your existing roof with tin. This means the installation costs typically include removing the older roof. Labor costs for installing a terne roof are $4.50 to $12 a sq.ft. or $450 to $1,200 per square, depending on the material and tin roof type. Stainless steel is easier to work with and may have lower costs than steel. Standing seam roofs are generally more labor-intensive with higher costs, but installing a flat-lock roof on a curve can also have higher costs.

Flat-lock roofs must be installed directly on the roof deck in tin roof installations. Standing seam roofs can install over an existing material if the roof is in good shape. However, most people prefer to remove the older roofing so that the deck can be inspected and repaired if necessary. Below are the average costs per square foot for installation, material, and tearing-off the roof.

| Project Area |

|---|

| $5.50 – $14 |

Also Check: How Do You Clean A Roof

Installation And Repair Usually Requires A Professional

DIYers have been known to install and repair metal roofing, but it is generally not advised. Metal roofing is generally available only through select retailers, and the techniques for installation and repair are specialized skills. If you opt for metal roofing, you will likely be calling a specialist should problems occur. Fortunately, such problems are rare with metal roofs.

How Is Insulation Installed In Existing Walls

In the same way, cellulose or foam from the inside of the walls from the outside to the outside. Cut a 1.5 to 2 inch diameter hole between each pair of studs at the top of the wall and use a hose to spray the grout or foam into the cavity. Replace the recesses, fill with a wooden trowel, sand and paint to restore the finish.

How much does it cost to replace a roof

Also Check: How Much For A Porch Roof

Types Of Metal Roofing Available

There are a few types of metal roofing available on the market today. Its come a long way since just large metal panels were being used for pole barns or lean-tos. Metal roofing shingles today can nearly imitate asphalt or slate shingles, but with the benefits of metal.

Also, the type of materials used to manufacture metal roofs vary and are most commonly tin, zinc, steel, aluminum, and copper. There are four main types of metal roofs: metal shingles, through-fastened or corrugated panels, modular panels, and standing-seam panels.

Disadvantages Of Metal Roofs

Despite their many advantages, metal roofs have some potential drawbacks.

- Affordability. Metal roofs can be as much as two or three times more expensive than other roofing materials. While the life of a metal roof is much longer, investing in a metal roof only makes sense if you plan to stay in your home long enough to enjoy the cost benefits.

- Noisiness. Metal roofs may be more noisy during a heavy rain or hailstorm than other products depending on the type of decking used during installation . Adding more attic insulation can sometimes solve this problem, but that may increase costs.

- Expansion, contraction and fasteners. Metal roofing material assemblies that are attached as large panels are designed to expand and contract as they warm and cool. However, both exposed and concealed fasteners have varying lifespans. Depending on the climate, neoprene washers and the screws used during installation may degrade and become dislodged over time.

- Inconsistency of color match. If a repair is required or a home extension is added years later, it may be difficult to find an exact match to the existing metal.

- Performance. If water accumulates anywhere on the roof because of poor-quality installation or repair, it can eventually cause serious damage. Low-grade metals may also be thinner gauge and less durable. Some metals rust in certain climates or dent more easily than others during hailstorms or installation.

Recommended Reading: How Do I Keep Moss From Growing On My Roof