Minimum Roof Pitch For Metal Building

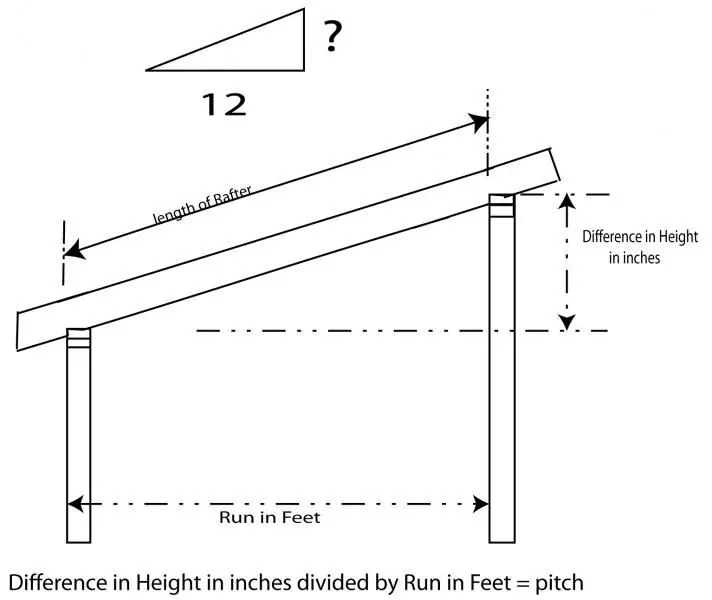

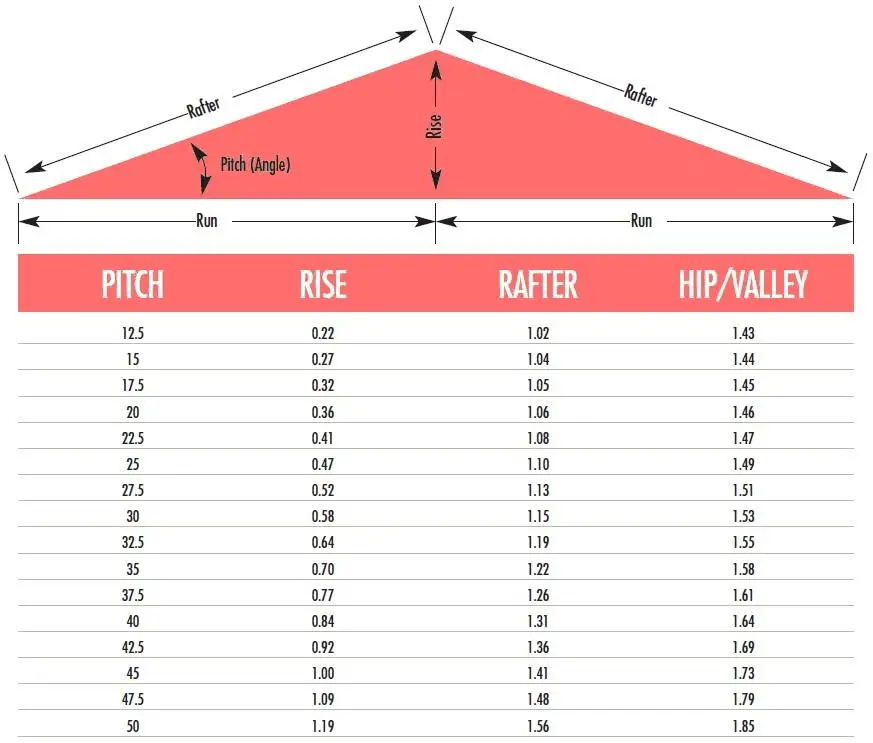

The pitch for a roof can be measured in degrees or ratio of rise to run. It is commonly defined as the number of inches the roof rises over one foot horizontal distance.

The metal roof doesnt stray far from other buildings with different materials. The height of the slant should be 3 inches for every 12 inches. The lower pitch range is between 1:12-5:12.

You will be charged more for these pitches because they are considered to be higher than others. The pitch of 5:12 is considered to be a minimum pitch for a metal roof.

Pros And Cons Of Various Roof Slopes

Low pitch roofs are easier to install and safer to walk around to complete repairs and maintenance. This is fortunate since flat roofs are somewhat more prone to leaks and require frequent inspections.

Low-pitch roofs are seldom used in regions of severe weather due to the stress of snow accumulation on roofs of structures.

Flat roofs can be significantly cheaper to install than a pitched roof, but they will often require more maintenance. Flat roofs are popular in regions of sparse rainfall and are favored by modern architects in contemporary designs.

Medium-pitched roofs come in a variety of styles and provide help with dispersing snow and rainfall while still being able to be inspected and repaired by the average homeowner by walking around the surface.

High-pitch, non-walkable roofs are dynamic and present an exciting appearance, but they are more expensive to install, and repairs will be left to roofing contractors with all the necessary safety equipment.

Minimum Slope For Asphalt Shingles

The requirements for an asphalt shingles roof are contained in the International Building Code. According to this code, the minimum slope for asphalt shingles is 17 degrees or two vertical units to twelve units in the horizontal.

In case a slope greater than this is necessary, then a double underlayment application must be used as per the requirements of the International Building Code.

Also Check: How Long Does It Take To Change A Roof

What Is A Low Slope

A low slope is a roof with a pitch less than 3:12 but greater than 1/4:12. The minimum slope for lapped, non-soldered seam metal roofs with applied lap sealant shall be no less than one-half unit vertical in 12 units horizontal . Lap sealants shall be applied in accordance with the approved manufacturers installation instructions. The minimum slope for standing seam of roof systems shall be one-quarter unit vertical in 12 units horizontal . Please note that in Miami-Dade and Broward counties, 2:12 is the minimum allowable slope.

Painted products are not as high of a concern since low slope roofs have limited visibility. There are lots of considerations you should keep in mind with low slope roofs since they have a high risk of water intrusion. Generally, water will remain on a low sloped roof for an extended period of time. Due to heavy storms such as hurricanes, the system will become submerged. This requires additional steps to ensure the system remains water-tight.

This type of roof is seen most often on large buildings with long runs . Low slope roofs also come with several complications such as sealing the roof mechanically up to 180 degrees. A low-slope allows for a lower-height building and requires less structural support.

Can A Metal Roof Be Put On A Flat Roof

If your flat roof is covered in metal, it is possible to install it. A metal roof over the flat roof area, over a porch, or over a door is a good way to enhance your homes appearance. Because of this, it is very common for homeowners to install a metal roof over a flat roof or a low-rise roof.

Why Metal Roofs Are The Best

It is critical to consider the type of roofing material, the slope of the roof, and the distance you will be standing on or walking across the roof when choosing a roof underlayment. The majority of metal roofs can be held up without difficulty, but slope may make them uncomfortable at times.

You May Like: Does A Metal Roof Increase The Value Of A Home

Installing A Metal Roof Over Shingles

If you currently have an asphalt roof and need to replace it, you may have an option of installing a metal roof over shingles.

This will enable you to save money on tear-off, which can be as much as $1,200-3,000.

Its best to speak with your roofer about this, because it may not be recommended depending on your roof structure, ventilation, and other factors.

Minimum Roof Pitch With Metal Roofing

March 31, 2017 | Filed under: Metal Roofing 101 Series, Roofing Help Videos, Roofing Installation

Most residential metal roofs require at least a 3:12 roof pitch and have no maximum roof pitch. That means there is at least 3 of vertical rise to the roof slope for every 12 it goes back horizontally. That is a 14 degree angle. Mechanically seamed standing seam metal roofs, commonly used on large warehouses and the like, can be used on much lower roof pitches. Some homes may benefit most from two types of metal roofing on different roof planes to accommodate different pitches on the roof. Under no circumstances should a roofing product ever be installed at a pitch lower than that recommended by its manufacturer.

Todd Miller has spent his entire career in the metal building products manufacturing industry. He is president of Isaiah Industries, an organization recognized as one of the worlds leading metal roofing manufacturers. Todd is currently Vice President of the MRA and a Past Chair of MCA . Through his website, he strives to raise the bar on standards and practices to provide property owners with the best possible products for successful roofing projects.

You may pull quotes from this article provided you include a link back to the original article on this site. You may not reprint this full article, or even a significant amount of the article, without explicit permission. To gain permission, .

Also Check: How Much Is The Tesla Roof

Common Roof Pitches For Metal Buildings

Standard metal building kits typically come with low roof pitch roofs ranging from 1:12 to 4:12. These roof pitches save on construction costs and reduce heating and cooling expenses. However, you can add valuable extra space, at not much cost, by installing a higher-pitched roof, like a sloped gable or hip roof.

Choosing The Right Low Slope Option For Your Metal Roof

Choosing the right metal roofing material is important when you have a low slope roof to ensure your roof will enjoy the proper performance and longevity that metal roofing is known for.

Snap Lock Standing Seam may be the right fit if:

- You have a pitch of 3:12 or greater

- You are located in a more mild climate

- You are looking for an easier standing seam installation

Mechanically Seamed Standing Seam may be the right fit if:

- You have a pitch of 1:12 or greater

- You are looking for the most weathertight metal roof panel

- You are looking for the most secure panel

- Your roof is located in very cold, extreme climates

7.2 Panel may be the right fit if:

- You have a pitch of 1:12 or greater

- You are looking for an affordable low slope metal roof panel

- You are looking to do the installation yourself

- You are looking for the widest availability of color options

R Panel may be the right fit if:

- You have a pitch of 1:12 or greater

- You are looking for the most affordable low slope metal roof panel

- You are looking to do the installation yourself

- You are looking for the widest availability of color options

Standing seam is considered the premium choice in metal roofing not only for its performance and long lifespan, but also for its clean lines and enhanced curb appeal.

Learn more about standing seam metal roofing and the 3 types of standing seam panels that are available:

Read Also: How Much Does A Roof Cost In Michigan

What Angle Should A Corrugated Roof Be

Corrugated roofing is an excellent material on traditional pitched roofs, but it is severely hampered when the pitch is below 5 degrees. As a result, all roofing manufacturers recommend that you install the roof with a slope of no more than five degrees, but you will not be guaranteed if it is installed flatter than that.

Metal Roof Cost Vs Premium Materials

Since metal is considered a high-end material, it makes sense to compare its cost to other premium roofs, such as cedar shingles, slate, synthetic slate, clay and concrete tile.

| Roofing Material | |

|---|---|

| $7 14 | 20 40 years |

Looking at the price difference vs benefits derived from high-end roofs, it is clear that a metal roof offers the best value.

Also Check: What Is The Price To Replace A Roof

Metal Roofing Costs Vs Shingles

The costs of metal roofing versus the costs of asphalt shingles or other types of shingles are somewhat dependent on your location and the type of property that you have, along with your initial starting budget.

Also, you should keep in mind that metal roofing has a much higher resale value than some other types of roofing, so consider that when you are choosing what type of roof you want to install on your home.

If you are choosing between metal roofing and shingles, keep in mind that metal roofing can be a great choice, because it can pay for itself via energy efficiency.

A metal roof can result in decreased home cooling costs, and it also has a great resale value due to its reliability and longevity.

With a metal roof, you will most likely not have as much of a need for maintenance and repairs, and you will probably not need to replace it as quickly since metal roofing tends to be fairly low risk in regard to premature roof failures and the subsequent need for replacement.

Metal roofing also tends to have a positive resale value if you change your mind or want to replace your roof for aesthetic reasons.

The national average for metal roofing costs around $18,500, but the resale value can possibly offset some of the costs of the initial install.

The lifespan of a metal roof can last from 38 60 years.

What Is The Minimum Slope For A Metal Roof

Metal roofs are ideal in applications where durability and speed of installation is important. However, inappropriately installed metal roofs can cause as much damage as they prevent.

Metal roofs are unique in that when installed according to the manufacturers directions and well maintained, they can last virtually forever. Metal roofs however, are subject to deterioration like rust prevention, rubber seal maintenance, and minimum slope requirements.

The most important rule to follow when installing a metal roof is to respect and follow the minimum slope allowed for the material. All roofing materials are judged on their ability to shed water effectively, including metal roofing.

Today we will discuss what a minimum roof slope means and why it is important when installing a metal roof.

Don’t Miss: How Much Is A Sheet Of Tin Roofing

What Happens If The Slope Of My Metal Roof Is Too Low

A low slope roof is generally considered any slope less than 3:12, which is the minimum for most metal roof products. Most roof materials, not just metal roofing, adhere to a similar requirement, like fiberglass/asphalt shingles. However, we reached out to Landmark Roofing and Siding about this to get more clarification. They mentioned, Roof slopes lower than 3:12 usually require some form of bitumen, which is a petroleum based roofing sealant.

Metal roofing panels require a minimum 3:12 roof pitch, or the water will move so slowly it can puddle. Since metal roofing traditionally uses no sealants, if puddling occurs at an overlap joint the water can seep between the panels, causing a leak. The same happens with unsealed nail holes, which is why most installers use grommet screws.

There Are Two Main Reasons Why Corrugated Roof Sheeting And Low Pitches Do Not Mix:

Flat skillion roofs are the most common way to increase the size of a traditional bungalow house and many builders and roofers simply slapped on some corrugated iron for the roof. This is the cause of most of the roof leakage problems with skillion metal roofs.

Modern architecture has birthed the demand for low profile roofs and builders and roofers still have a problem in this modern era of simply not understanding the limitations of corrugated roofing. I see countless examples of corrugated roofing on brand new low pitched roofs. These are water leakage time bombs. and many roofers think they can fix these roofs with a bit of roofers silicone until they find that roofers silicone is not always the way to do a roof repair properly.

UPDATE:

Answer to a smart question: As a roof gets longer, does the slope need to increase?

Read Also: How To Replace A Shed Roof

Attain High Marks For Low

Low-slope metal roofs have simple geometries, and are easier and less expensive to install that medium-to steep-slope roofs. Low-slope metal roofs require less material, which reduces the overall load on the buildings structure. Low-slope roofs are not totally flat, their roof slope generally ranges from 1/4:12 to 3:12. Minimum metal roof slope depends on the roof profile, building design, climate and site location. Typically, large-footprint, single-story warehouses and pre-engineered metal buildings will utilize low-slope metal roof systems.

Jim Bush, vice president of sales at ATAS International, Allentown, Pa., believes large buildings with long-slope runs often are best applications for low-slope roofs as the overall height of the building can be minimized with low-slope systems. Frank Resso, PE, president, Resso Engineering, Newnan, Ga., agrees, saying that low-slope metal roofs tend to be used on buildings that are larger in overall area with long runs from eave to ridge, to reduce the total height of the roof and to minimize the structural requirements of the supporting framing. Buildings with low-slope metal roofs tend to be more concerned with system performance than the aesthetic benefit that a more visual roofline could promote, Resso says. From a budget and aesthetic standpoint, flat built-up roofing -to-metal retrofits are prime candidates for low-slope metal roofing.

Inadequacy Of Roofing Felt As A Vapor Barrier For Asphalt Shingles In Hot Humid Climates

A Building Sciences Corporation report lso elaborates the usefulness of placing a vapor barrier on the roof deck below shingles in hot humid climates. BSC points out that:

Unvented roofs with asphalt shingles in hot humid climates require a vaporbarrier between the asphalt shingles and the roof deck. This is because asphalt roofing materials store water from dew or rain.

Thus asphalt shingles form a water reservoir not unlike wood shingle or shake roofs.

The report argues that this stored moisture is driven inwards when sun strikes the damp or wet roof surface, and it continues to argue that moisture is driven through vapor-permeable roofing paper, felt, and plywood or OSB roof decking, thus ultimately into the attic space

But unlike an asphalt shingle roof nailed directly to a roof deck, a wood shingle or shake roof that has been installed using best practices includes a disposal path for water absorbed in the roof surface: an air space between the wood roofing and the roof deck, or the installation of wood roofing over spaced nailers or skip sheathing.

In cool or temperate climates this does not present a problem because the combination of heavy wetting from due or rain i snot combined with solar heating at high outdoor temperatures, say the authors who go on to argue that that buckled roof shingles observed in the morning relax during the day.

But on an un-vented roof moisture driven inwards in hot humid climates, needs to be addressed.

[QUESTIONS-DF:

Don’t Miss: Can You Redo Your Own Roof

Keep The Roofline Simple

The most effective building design for snow country is a straight, single- ridge gable roof. Simple gable roofs shed snow and ice more quickly than complicated rooflines. Roofs with valleys, dormers, and other obstructions causes snow on metal roofs to building up erratically.

The slope of the roof is also extremely important. Too shallow a slope causes snow on metal roofs to stay there longer, increasing the strain on the structure. Too high a slope may create a hazardous situation when great amounts of snow or ice slide off all at once.

Sliding snow and ice actually wrecks more havoc and results in more damage than excessive snow piled on the roof. Snow can weigh 30 pounds-per-cubic-foot or more. If your roof has accumulated three feet of snow, thats 90 pounds-per-square foot or more.

In the Sierra Nevada Mountains snow, loads are the most extreme in the U.S. The moisture coming in from the Pacific Ocean makes snow in this region extremely heavy. Locals call it Sierra Cement. In the Lake Tahoe area, for example, ground snow loads may reach 450 pounds-per-square foot!

Sliding snow often shears off chimneys, vents, and other roof obstructions. Massive snow suddenly sliding off a roof sometimes kills the unsuspecting caught below it.

The ideal location for an entrance is on the endwall under the gable. Designing the entrance on the opposite end of the prevailing wind is preferable.