How To Install Corrugated Metal Roofing Like A Pro

Step By Step Corrugated Metal Roofing Installation Instructions Specifically For 7/8 Corrugated Metal Roofing Panels.

If you have a different type of exposed fastener metal roofing panel these videos will still be extremely helpful. Most of the installation techniques are the same or extremely similar for metal panels such as: R Panel/PBR Panel, 7.2 Panel/Western Rib®, U Panel, and Ag Panels.

- Installation Of Synthetic Metal Roofing Underlayment

- Squaring A Roof, 1st Sheet Placement, And Fastening

- Eave Trim, Gable Flashing , And Ridge Cap

- Valley, Transition, Sidewall, And Endwall Flashing

- Gutters And Downspouts

Recommended Reading: Is The Tesla Solar Roof Worth It

How To Fibreglass A Roof In 4 Steps

Fibreglass roofs are made up of several different layers, creating a strong, durable, and highly weatherproof system. To understand the role of each of these, its useful to at least grasp the theory of how to fibreglass a roof.

For the vast majority of people, the most sensible and cost-effective way to install a fibreglass roof is to engage an experienced specialist. This is because fibreglass roof installation is an involved process, and mistakes can lead to costly issues.

Additionally, improper installation is the most common reason for fibreglass roofs developing faults. As such, its always best to engage with a specialist fibreglass roofing contractor to discuss the needs of your product.

In this guide, well cover the four main stages of fibreglass roof installation. Youll gain enough of an understanding of how to fibreglass roof to allow you to make an informed decision about the needs of your building project.

It should be noted that this is the most common method for installing a wet lay fibreglass roof. By contrast, other systems like Dryseal roofs are mechanically assembled onsite

Lets dive right in.

Why Is Fibreglass An Excellent Flat Roofing Material

Fibreglass is an incredibly effective flat roofing system with many applications. It has been used extensively in the construction industry, accounting for a large proportion of the GRP fibreglass composites market.

As a composite, it offers exceptional properties strength, durability, broad chemical resistance, waterproofing, abrasion, and moderate impact resistance as well as a range of other features. It is also very cost-effective as a flat roofing system.

Don’t Miss: How Long Does It Take To Build A Roof

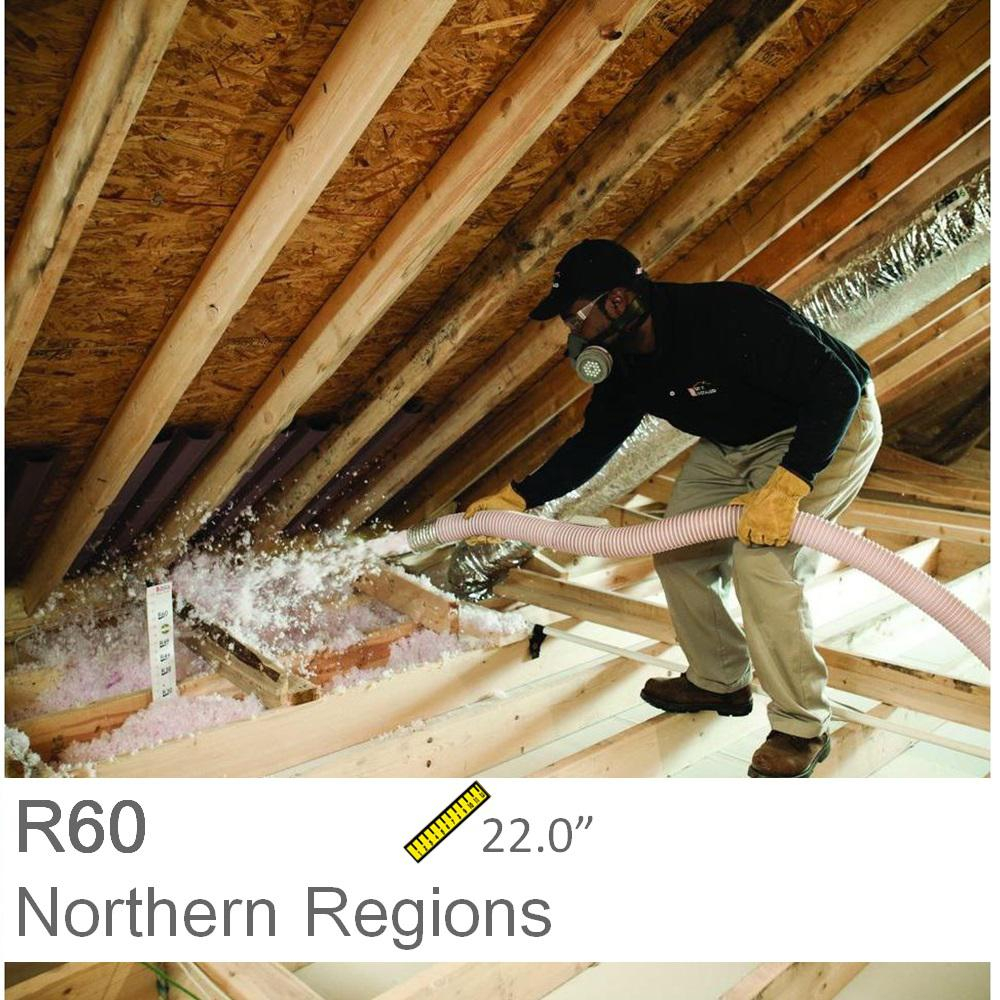

How To Cut Insulation

PRO TIP: To cut through thick batts, use a utility knife that has a snap-off blade . Extend the blade out about 3 inches, then tighten the locking knob. The extra-long blade makes it much easier to slice through thick insulation. Just be careful with this super-sharp, long blade!

Why Choose Corrugated Fiberglass Roofing Panels

- Posted onJune 26, 2021

Fiberglass roofing panels are specially produced to thrive in harsh conditions that come with the territory of industrial, wastewater treatment, and commercial plants. But what sets them apart from traditional metal roofing and how could FRP better serve your work environment? Cost, weight, durability, and ease of installation are generally the most important factors when choosing a roofing material.

Corrugated fiberglass is resistant to insect damage, rot, elevated temperatures, harsh chemicals, and more all while having high tensile strength. Additionally, fiberglass is extremely easy to work with as it may be cut, drilled, sawed, etc. without suffering damage and is easy to install.

These are all major reasons why owners, maintenance, and plant personnel prefer corrugated FRP for their industrial applications.

You May Like: How Much Does A New Roof Cost In Chicago

What Underlayment Should Be Used Under Metal Roofing

Non-perforated, asphalt-impregnated felt has traditionally been used to provide roof underlayment on steep-slope metal roofs. The amount of felt underlayment used varies depending on the type of felt, ranging from organic reinforced to inorganic reinforced.

Metal Roofing: The Pros And Cons

A metal roof can be installed on your home to create a more modern appearance while lowering your utility bill. It is, however, critical to understand that roofing cannot be done with all types of metal. Before using metal roofing over plywood, you should thoroughly examine the plywood to ensure that it meets safety standards. Tyvek also has numerous advantages when compared to other types of metal roofing, such as its high durability and ease of installation.

Rigid Foam Insulation Under Metal Roof

Rigid foam insulation is a great option for metal roofs because it provides a high R-value, meaning it will keep your home or building cooler in the summer and warmer in the winter. It is also impervious to moisture, so it wont rot or grow mold and mildew.

Is applying rigid foam under metal roof ok? This is done in preparation for the installation of Solar panels and rainwater harvesting. Roofs are generally outfitted with ventilation to avoid overheating of roofing materials. Will that be a concern with metal roofing?

You May Like: Will Hail Damage A Metal Roof

*** Thanksgiving Recipes ***

These roasted brussels sprouts get a fair amount of spice from the crushed red pepper flakes, which cuts

After trying every turkey-roasting method under the sun, Ive finally settled on this as absolutely the

We love how the cinnamon-scented streusel topping lets the juicy berries peek through.

Italian sausage and a heap of Parmesan cheese lend signature flair to the easy Thanksgiving dressing

Its all about the layers and ruffles in this dramatic seasonal pie.

Poach quince in rosé with a dash of cocktail bitters and a few warm spices, then assemble into a tart

Leave the sausage, nuts, dried fruit behind in favor of this easy, vegetarian-friendly stuffing recipe

Alton Browns turkey brine recipe from Good Eats will give you a flavorful Thanksgiving turkey with juicy

Bone-in turkey breasts are easy to find, and as impressive as a whole bird when you roast them in butter

This recipe was handed down by my great-grandmother. It is a family favorite that we make every Thanksgiving.

Cutting leeks into large pieces gives them a presence equal

This crunchy crumble is the perfect topping for an ice cream sundae, easy apple crumble, or our Build-Your-Own

Also Check: How Much Is Tesla Roof

How To Insulate Walls

Walls are typically insulated with faced batt insulation because it comes precut into strips that fit standard 8-foot-tall walls. However, faced roll insulation is also perfectly acceptable. Youll just have to cut the strips to length to fit between each stud.

Caution: Installing fiberglass insulation exposes you to fine glass fibers, which are irritating to the skin, eyes, and lungs. Whenever you handle the insulation, wear long pants, a long-sleeved shirt, tight-fitting eye goggles, gloves, and a dust mask, or better yet, a dual-cartridge respirator. To keep the itchy glass fibers from sticking to your neck, sprinkle baby powder onto the exposed skin around your shirt collar.

There are a few different ways to slice through insulation, but the simplest method for do-it-yourselfers is to use a straightedge and utility knife as shown in the photo below.

Don’t Miss: How Long Does It Take To Change Roof

Laying The Chopped Strand Mat

Before the chopped strand mat is laid out, the deck must be clean and dry and all the trims fixed in place. The mat has a cut edge and a feathered edge. Always overlap the feathered edge on top of the cut edge.

The mat is usually best laid parallel to the drip trim. Start by rolling the mat out. Overlapping the trim by at least 50mm, but not over the edge of the trim. Leave the ends long at this stage.

Roll out each 1m wide strip overlapping each time by at least 50mm right across the roof. The ends can be cut off with a Stanley knife into the corner of the trim to leave a straight and neat edge. Decide on the best place to finish laminating the roof from. Roll the mat up to the furthest point from the ladder.

Leave the rolls on the roof where they have been laid out to avoid any mix up if there is a deviation in size or angle from one length of mat to another. Cut 200mm squares of mat for each corner and 200mm strips of bandage for each trim joint.

How To Install High To Low Transition Trim For Metal Roofing

Transition trim is used when you have a roof that has two different pitches. It’s located where the two different roof pitches meet so the metal roof does not leak.

Transition flashing is also referred to as pitch break trim and comes high to low or low to high.

When you have metal roofing sheets that are running up into a wall, you will need to install endwall flashing to help control the water runoff. It will prevent roof leaks at this vulnerable location.

Endwall flashing must be installed after installation of the sidewall trim.

Also Check: What Does A Roofing Consultant Do

Install Shingles Around Vents

Roof around the vent. Cut the upper shingles so they fit snugly but do not ride up on the flashing’s raised portion the shingles should lie flat at all points. Where shingles overlap the flashing, attach them with roofing cement rather than nails. Cover any exposed nailheads with dabs of roofing cement.

Editor’s tip: To roof around a dormer or other obstruction, install shingles all the way up and run at least one course past the obstruction. The bottom of these courses must be nailed higher than usual so you can slip shingles under them later. Now you can snap a new bond line to align the shingles on the other side.

Laying Out The Fibreglass Mat

While the first layer of resin is still wet, its time to start rolling out the cut pieces of fibreglass matting and applying the top layer of catalysed resin. Each roll of matting is laid down, and coated thoroughly with the correct quantity of resin.

As the laminate begins to turn transparent, a consolidation roller is used to ensure that the laminate sets correctly. In particular, at this point there is a risk of pinholes or resin starvation occurring, which can lead to leaks or water ingress in the roofing system.

In extreme cases, these might require the entire roof to be started from scratch.

Also Check: How To Clean Moss Off My Roof

Comparison Of Fiberglass Shingles

So whats the difference between asphalt and fiberglass shingles? Fiberglass shingles are actually composed of asphalt as well, and when most people today say asphalt shingles, they are actually referring to fiberglass shingles.

You will often see the terms used interchangeably. However, asphalt shingles can also refer to organic shingles.

Traditional asphalt shingles have been waning in popularity in recent years and have, for the most part, fallen out of use.

Their organic core is highly susceptible to rot and water damage. This paper base understandably also leads to a lower fire protection rating. They are also much heavier than fiberglass shingles, which makes them more difficult to work with.

Fiberglass shingles are created with a woven fiberglass base as opposed to a wood-based one. This base mat is then covered with waterproof asphalt and granules of ceramic that help shield your roof from UV rays.

Since the only difference is in the base, fiberglass and traditional asphalt shingling look identical as a finished product.

Fiberglass asphalt shingles are more expensive than organic asphalt shingles but for a good reason. Their value as a roofing material is greater due to their increased durability and longevity.

While a traditional asphalt roof may last only 10-15 years, and installation using fiberglass shingles can stretch the life of your roof a great deal ranging anywhere from 25 to 50 years! This makes the increased cost well worth it.

Please Read All Instructions Before Beginning Installation

These guidelines are provided in good faith to help preventinstallation problems caused by common errors. Kemlite Company,Inc. bears no responsibility for installation actions taken ornot taken.

There are many nuances of installation that KemliteCompany, Inc. assumes are general construction knowledge to anexperienced installer such nuances are not included in theseinstructions. Rather, these installation guidelines are strictlyrecommendations are not intended to serve as a step-by-step,foolproof installation checklist. Selection of an experiencedinstaller is the sole responsibility of the project owner andarchitect.

If you have any questions about installation techniques foryour particular project, please call 800-238-6874 or731-764-2153 and ask for an Office Sales Representative.

Read Also: What Is The Cheapest Way To Replace A Roof

Cleaning And Insulating The Roof

What You Need To Know About Grp Fibreglass Roofing Systems

Glass Reinforced Polyester, also known as GRP fiberglass roofing, is mixed material and reinforced with first-class glass fibers. It is designed especially for flat roofing system applications and one of the most popular roofing types in the market. You can use it for domestic properties, from housing up to huge industrial buildings.

Fiberglass roofing can be placed quickly and cover huge areas such as industrial complexes and warehouses. Many of the flat roofs you can see in commercial areas contain fiberglass.

The simplicity and safe installation of GRP roofing and the finished product are known as having a longer lifespan than the felt roof.

GRP roofs start with applying a resin catalyzed layer for the coating to have the best quality, then wait until the roof deck is completely dry . Then a sheet of fiberglass matting is placed on the top and followed by a second coating layer of resin catalyzed to complete the system.

Advantages of Having GRP Roofing

- Convenience: When we talk about the selection of roofing materials, nothing gets more convenient than fiberglass. The smooth nature of its form means no wastage, more environmentally friendly, less pressure on surroundings, and the best replacement to felt which is not often recycled. From the manufacturing site, the material can be pre-cut. Notably, the transport is fast, and the installation process is straightforward.

Fiber Roofing Installation

Don’t Miss: What Does Tpo Roofing Stand For

Unit Costs: How Pros Price

Unlike websites which blend pricing from dissimilar jobs, Homewyse creates custom estimates from Unit Costs. The Unit Cost method is based on job specific detail and current costs. Contracting, trade, design and maintenance businesses rely on the Unit Cost method for transparency, accuracy and fair profits.

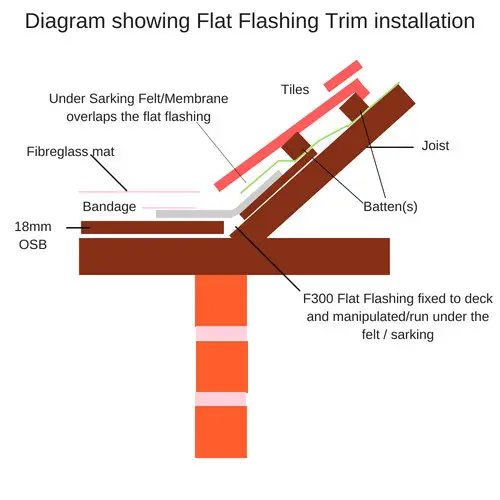

Applying The Grp Edge Trims

Edge Trims are manufactured from GRP. One side of the trim will have a matt finish for high adhesion and the other side will be glossy.

Most trims are fixed to the decking board with 13mm galvanised nails or staples. The exception to this is the application of the F300 Flat Flashing and D260 Fillet Trim. These should be fixed with a PU Adhesive.

Also Check: Can You Put Solar Panels On A Tile Roof

Shingle Peaks And Hips

When you reach a peak or hip, shingle all the way up the first side and cut the 3-tab shingles just below the ridge. Shingle the other side and allow these pieces to overlap the ridge by no more than 4 inches.

Editor’s tip: When hips meet at a ridge, you may have to improvise to handle awkward areas. Just be sure that water will not seep in between shingles as it runs downward. Where two hips meet a ridge, cut a triangular piece to cover the joint. Cover any exposed nailheads with dabs of roofing cement. Then apply ridgecaps.

If you have a hip that runs into the main roof, cover the area with WSU when you are installing the sheathing cut the WSU so it lies flat at all points. Then cover the resulting V-shape notch with another piece of WSU. When you install the shingles, leave one shingle unnailed so you can later slip a ridgecap under it.