Cut The Plastic To Length

Youll want to unroll the plastic with a little more length to run from the top of the roof to the edge of your roof . Dont unfold your covering yet and cut it to length with a utility knife. You can use one of your 2×4s as a guide to make the cut as straight as possible. Once it is cut to length you will unfold it to make a section that is long enough for your roof, and about 8 feet wide.

Metal Roof Option #1 Repair And Maintain

Metal roof systems can be repaired and maintained. These roof systems may have an estimated use life of 30 years or more if the original installation was a quality installation. It is strongly recommended that metal roof systems be reviewed on a bi-annual basis to catch problems early on before they develop further.

The key to maintaining a metal roof system is to review the roof system on a regular basis. It is best to catch problems early on before they can develop further. Problems including oxidation can be addressed early on for a reduced cost. Locating fasteners that have started to back out before and re-tightening them can reduce leaks and help maintain the roof system.

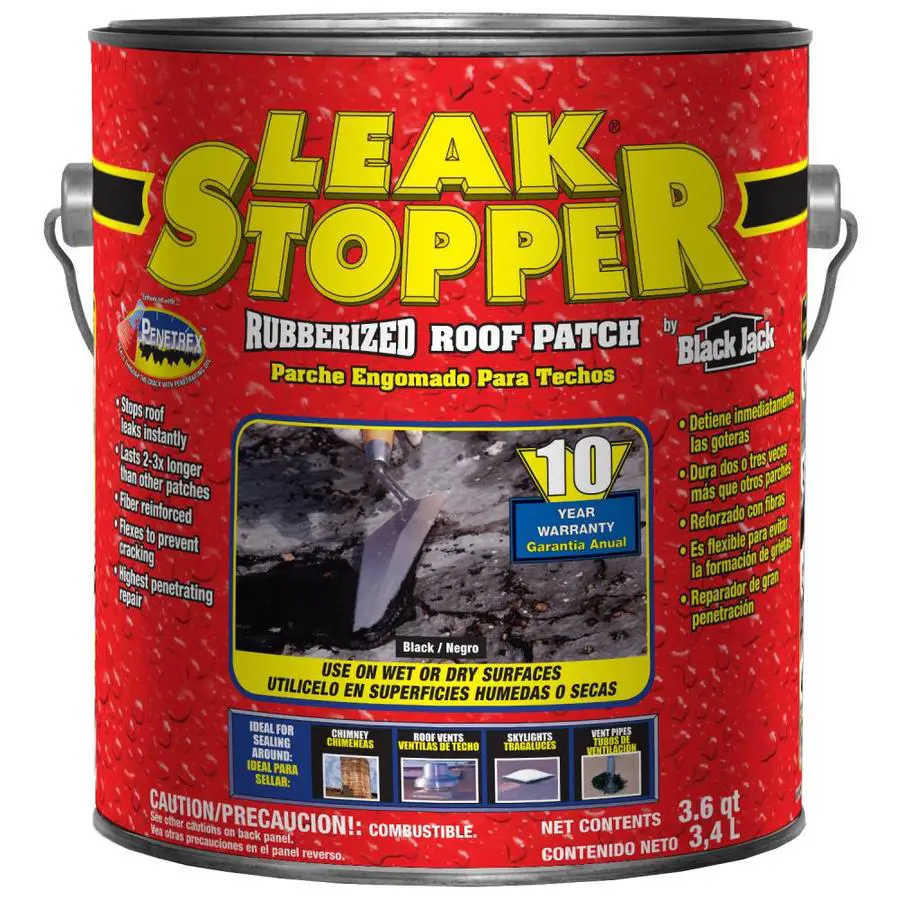

Seal The Leaking Point With Tar

To achieve the desired when sealing the leak, you must wait until the leaking point is dry.

Waiting until the roof is dry helps you get the right leaking point and ensures the roof patch sticks on the leak.

Now that youve identified the leaks location, you can go ahead to make a temporary patch on the leaks. But just before then, you can use a piece of marking chalk to draw a circle around the leak. This will help you in a significant way the next time youre ready for a permanent fixing of the roof.

Doing the leak sealing requires pressing roofing tar on a piece of shingle or plywood. With the help of a knife, apply any of these materials to the leaking point. Please make sure the targets round the leaked patch, so it sticks firmly in place. To achieve maximum results, you can use a scraper to cover the entire leaking point and surround it with the caulking and ensure it evenly spreads.

Also Check: Where Do You Put The Screws On A Metal Roof

What To Consider When You Own Or Buy A Property With A Metal Roof

If you own a property with a metal roofing system or are considering buying one, keep all these characteristics and other potential issues in mind when you are negotiating the deal and when you are working with your insurance company .

In regard to metal roofing, as in any other property or assets you own, be sure to document everything early and often. Youll thank yourself in the future.

Replace Affects Metal Roofing Sections

If some sections of your roof are missing, replacement is the only option. You can also replace badly corroded roof flashings and panels.

In addition, you can replace roofing fasteners and washers, which have backed up or deteriorated, with new ones. You can also remove old metal sealants and recaulk the joints that need sealing.

Recommended Reading: Where Do You Put Screws In Metal Roofing

Can A Metal Brake Be A Cutting Guide

You can minimize or eliminate waves in the metal when cutting sheet metal such as tin or aluminum if you use the metal brake tool as a cutting guide. When I had access to a brake and had to cut sheet metal, I would insert the piece of metal into the brake tool and push the clamping lever to lock the break’s jaws down on the sheet metal. Using a razor knife equipped with a new blade, I would make score the metal along the top jaw of the break. The razor would actually cut partially through the metal and when the brake handle was rotated up and down several times, the metal would separate much as the pop tab on an aluminum drink can breaks when bent back and forth.

This is a soldered seam between two pieces of the 40 pound tin. You can also clearly see the edge that has been created with the break. This bend in the metal actually keeps the metal very straight.

Finding The Right Expert

While applying a roof coating can help to restore your roof and keep both air and water from penetrating the surface, it is important that you hire a qualified professional team that knows the proper way to apply the coating. Otherwise, the problem may remain. The expert crew at Rosies Roofing and Restoration know the importance of applying a 10 ml base coat to fill those cracks and crevices, followed by another 10 ml top coat to protect the roof from dangerous UV rays and weather.

Find out more about the metal roof coating options the Rosies Roofing and Restoration team offers. Call today to schedule your free consultation.

You May Like: Shingling A Shed

Metal Roofing Issue #: Fastener Issues

The metal paneling on your roofing system is brought together by one of two different types of fasteners: clips or rubber washerfasteners. The clips fasten in a way that conceals the metal seam laps. They typically involve a sealant to bind the metal paneling of the entire roof together.

Fasteners with rubber washers are self-drilling and can be put as close together as every two square feet. By putting them in close proximity, the seam laps of the metal paneling are held flush without the additional need of a sealant or butyl tape.

Over time, these fasteners can pop out, leaving holes or gaps in the metal seam laps, which can allow water in and paves the way for other issues down the road.

Some metal roofing systems are much better at holding a tighter seal, such as standing seammetal roofing systems.

Buy & Prep The Roof Plastic

You likely dont keep roof plastic just hanging out in a closet. So, youll have to head to the hardware store or call for help. Plastic roof covering comes in 4-foot rolls of polyethylene. Buy some and head home to get it placed on your roof. Youll also need some 8-foot 2×4s to act as anchors for your roof covering.

Read Also: Repair Roof Trusses

Choose Proseal Contracts For Your Flat Roof Waterproofing Needs

ProSeal Contracts is a waterproofing company in Singapore with more than 20 years experience. As one of the leading waterproofing contractor companies, we use the highest quality of materials to ensure long lasting results. Trust us to assess, choose and apply the right waterproofing procedures for your buildings needs.

Our waterproofing methodology for a RC Flat roof is a 5 coats that ensures years of protection against water leakages. Additionally, it insulates against deterioration from carbonation, acid or chemical attack

Causes Of A Leak With Metal Roofing

Metal roofing is typically made from copper, aluminum, zinc or one of three variations of steel, and can come in different options of roofing systems, like a standing seam metal roof.

Each type of metal roofing material and system comes with its own set of pros and cons. However, metal roofing is one of the most durable types of roofing youll come across.

Under ideal circumstances, your metal roofing wont require much upkeep or even replacement for a long time. With painted metal roofing, you can expect its lifespan to be between 40 and 70 years with little to no issue. It should also retain most of its initial reflectance and emittance for just as long.

If you find yourself with a leaking roof, the important thing to understand is that the cause isnt the type of metal youve chosen or the quality. The issue can typically be traced back to the installation.

Lets take a closer look at the common causes of a leaking metal roof, and how you can help fix these problems with a trusted commercial roofing company .

Recommended Reading: Roof Replacement Cost In California

Ways To Stop A Flat Roof Leaking

When it comes to leaks, low pitch roofs are the most vulnerable.

Roofs between 1 and 4.9 degrees are considered to be low pitch. Only a few types of roofing profiles are made to be installed at such low degrees, including mono clad and concealed fix . There are more options than these, but if budget is a priority, the profiles listed above are the best value.

Repair Affected Roofing Parts

Some roofing parts may need repairs. These include under-driven or overdriven screws, backed-up fasteners, misaligned roofing panels, and flashing edges, among other things. The issues affecting these roofing parts will determine how they are fixed.

For example, misaligned metal roof panels may need to be readjusted and reinstalled. And if the flashing on the roof has small holes, these could be patched up using roofing cement. And those whose edges stick out can be flattened and then nailed down after applying roofing tar. Finally, you can caulk the edges and seal them to prevent future leakages.

Recommended Reading: How To Repair Roof Trusses

Do You Own A Building Or Home With A Metal Roof System

You might be responsible for managing a commercial or industrial property that has a standing seam metal roof system. Metal roof systems represent a significant portion of the overall roofing systems in the United States. The chances are very good that you have come across a metal roof on a building that you are responsible for.

If you have been responsible for a metal roof system you most likely have had to deal with metal roof leaks. The details that make up a metal roof are unique to these systems. And as a result the repair options are unique as well.

Metal roof systems are used on a wide variety of buildings. They are installed on residential applications which tend to be on steep slopes. They are also installed on commercial and industrial buildings. Some industrial buildings utilize the metal roof system as both the waterproofing system as well as the structural roof deck.

Metal Roofing Issue #: Missing Or Badly Secured Paneling

If the installation of your roof panels is done poorly, theyll be prone to shifting or blowing away with high winds. This happens when the fasteners arent secured properly. Metal roof panels have to interlock correctly and securely, otherwise, youll lose bits and pieces over time.

Most metal roofing can withstand wind up to 110 miles per hour when installed correctly. If youre losing pieces of your metal roof, your installer likely didnt do their due diligence upon installation.

Read Also: How Many Screws Per Square For Metal Roofing

Common Sources Of Metal Roof Leaks

Metal roofs have unique characteristics that can cause leaks and widespread damage. The difference between a metal roof and a traditional flat BUR or modified roof is that a metal roof is NOT designed to be waterproof. It is designed for water flow, meaning there should never be any ponding or standing water on the roof for an extended period of time.

So what causes metal roofs to leak? Here are some of the largest culprits.

General Metal Roof Problems

There are four general problems that metal roofs run into roof leaks, blow offs, punctures & tears and ponding.

Roof leaks are a common problems that homeowners face with metal roofs. For example, poor workmanship in the initial installation phase may have resulted in both gaps and punctures in the roof. Such openings allow for water to leak through over time.

Blow-offs also occur due to poor installation. When the flashing is not properly attached, the resulting open seams and laps provide insufficient support for the roofing, thus allowing to be blown off when face with heavy winds.

Metal roofs are also vulnerable to punctures or tears. Typically, this occurs due to excessive human traffic on the roof or from heavy debris that land on the roof due to a storm. It is advised that minimal weight and stress be placed on metal roofs since they are thinner than most.

Ponding refers to the situation whereby water accumulates on your roof. When ponding occurs, excessive pressure is placed on the roof since it carries the ponds weight. Moreover, ponding weakens any waterproofing systems and allows for moisture to slowly creep past the surface.

Read Also: How To Extend A Metal Roof Overhang

How Do You Make Flashings

Virtually all professional roofers own a tool called a metal brake that enables them to quickly create a crisp bend in the metal flashing that matches the angle of the roof where it meets the house. They typically add a second small bend of about ten degrees one-half inch in from the edge of the metal that overlaps the shingles. The addition of this second break or bend takes the waviness out of the metal that often happens when the metal is cut using a traditional metal-cutting scissors or snips.

WATCH THIS VIDEO to see a flashing with a similar kick-out bend:

Emergency Roof Repair Services

If you need emergency roof repair services because you have a leaking roof, Right Way Roofing, Inc. is here to help! Our team has been serving the Phoenix Valley in Mesa, Phoenix, Tempe, Chandler, Gilbert, and valleywide for 3 generations. We are family owned and operated, so we always keep in mind how much your home means to you and your family. We strive to always work quickly, affordably, and provide the longest lasting roof repair services in the state of Arizona!

24 Hour Emergency Service Available

You May Like: Shingling A Shed Roof

Why Metal Roof Leaking At Ridge Should Be Handled

Manufacturers and industries will always assure you that their products are perfect and foolproof, but in reality, there is no such thing as a perfect product. As time goes by, you will notice that the metal frameworks has slowly been rusting away.

Metal roofing is no different in this situation

When it comes to this situation, metal roofing, just like every material out there, can deteriorate. This isnt your fault, of course, since this is beyond anybodys control. In terms of durability, however, metal roofing materials seem to run across fewer problems than their asphalt and concrete shingle counterparts.

Knowing is half the battle and educating customers about potential problems on metal roofing that might and might not happen can help them weigh in on what they want to purchase.

Well be discussing some aspects that you have to take into account if youll be opting to have metal roofing installed on your property.

Sealants And Tapes Are Effective For Repairing Metal Roofs Leaks

It’s been said that if a metal roof is perfectly installed, there is no need for sealants. Perhaps therein lies some truth, but perfection is elusive, especially under field conditions. All roofs will leak at some point, but metal roofs are particularly challenging. Metal has a high coefficient of expansion, so it moves more extensively with temperature swings. To complicate matters further, metal roofs feature flashings and other details that also move along different directions. Further, sometimes mechanical seamers do not work correctly. They can get out of adjustment, causing as many as half the seams on a finished roof to be deficient. The result: avenues for water. Fortunately, there are products that can remedy the situation effectively.

Two classes of products are designed for repairing metal roof leaks: sealants and tape. Sealants are ideal for the gaps formed by mechanical fastener heads and other penetrations. Most metal roofs have fasteners and, over time, these will back out from expansion/contraction cycles. Missing heads, loose heads, heads with the washer gone are typical. The correct approach to repairing these leaks is to remove the screws, put in a new washer and fastener, and then dab a high-quality sealant over each head.

Don’t Miss: Skylight In Metal Roof

Metal Roofing Issue #: Surface Rust

Depending on the finish you apply to your metal roofing, rusting may occur sooner than later. Rust is a normal reaction when metal is exposed to the elements. But fortunately, rust doesnt automatically equate to leaks.

However, if you notice rust on your metal roofing, address it immediately. Rust left unattended will spread and cause damage. The coating will begin to peel, the metal will begin to scale, and eventually, itll eat away at the metal causing holes. All of this can lead to severe structural damage.

Its important to use a rust inhibitor to stop the rust from spreading. It wont kill off the rust or stop it completely, but itll buy you enough time to have the necessary repairs done.

How To Find A Leak In A Metal Roof

Rain is the number one enemy of your roof, and July is the rainiest month of the year in Virginia. So this year, learn how to find a leak in a metal roof and keep your home safe.

As Virginia is pounded by rain this time of year, you need to be more vigilant than ever about leaks in your roof. How can you find them, and what do you do if there is a leak in your roof?

Heres everything that you need to know.

Recommended Reading: Briarwood Pro Shingles

Hydrostatic Vs Hydrokinetic Designs

A separate design characteristic of a metal roof system is the slope. Metal roof systems can be installed in either a steep slope or low slope application. Forgetting to consider the slope can be a major source of problems for metal roof systems.

It is important to consider the slope of the roof when designing, installing and maintaining a metal roof system. The NRCA defines a low-sloped roof system as any roof with a slope less than 3:12. All other roof systems are considered steep sloped.

Hydrostatic metal roof systems are designed to hold water until it can drain. These roof systems are capable of holding water without the roof system leaking. Typically these metal roofs are found on larger pre-engineered metal buildings. These larger structures are more costly to design with a steep sloped roof assembly. Additional hydrostatic metal roof systems can be found on residential applications. Tin and copper metal roofs can be installed with soldered flat seams in a hydrostatic system.

Hydrokinetic metal roof assemblies are designed to shed water. These systems are designed for steep slope applications. Steep sloped applications are found on residential and commercial applications where water cannot remain on the roof system. If the water is retained on the roof system it can create hydrostatic pressure forcing water into the details and creating metal roof leaks.