What Is A Roof Gauge

Gauge refers to thethickness of the metal panel and is represented in number form. Most metal roof and metal siding panels on the market are between 20- 29 gauge, with 20-gauge being the thickest and 29-gauge being the thinnest panels sold. These numbers refer to the and they have a range. For Example, 26 gauge could be a steel as light as .0179 or as heavy as .0217.

S To Choosing A Perfect Metal Roof

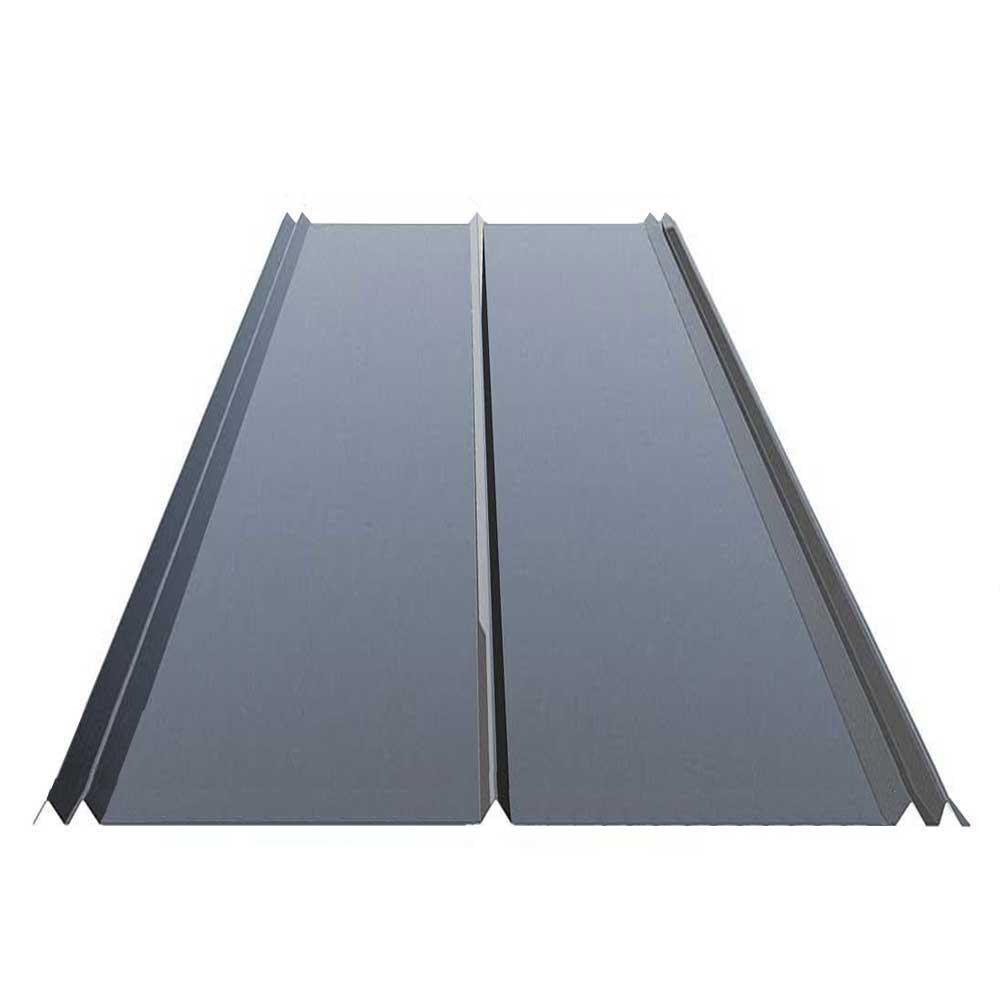

As you go through the process of choosing a metal roof for your home the first step is determining the panel type. Here is an article that will help you with that: Exposed Fastener Metal Panels v. Standing Seam Systems For Metal Roofs

Secondly, you have to determine the gauge of the steel. This article should give you a good idea of what gauge you should consider for your home.

The next step is to determine the type of paint system and the color of your metal roof. This article will help you with that decision: Metal Roofing Colors: 5 Tips To Pick The Best Metal Roofing Color

You Should Use 26 Gauge Metal Panels If:

- The panels are being installed in a climate with extreme weather conditions .

- Longevity is a top priority and you want panels that will last longer.

- Appearance is a top priority and you want a product with greater resistance to dents.

- You are building an open frame structure, such as a pole barn. While 29-gauge can be used for the walls of small barns, 26-gauge is advised for the roof and walls of larger barns.

You May Like: What’s The Cost To Replace A Roof

Metal Roofing Gauge Thickness For Panels That Will Be Installed Over Metal Purlins

When a metal roofing panel is installed over metal purlins the strength of the panel becomes extremely important. The metal roofing panels need to be able to span the distance between the purlins and also handle the load and wind uplift. There are load charts and uplift charts available online that will show you the capabilities of the panels.

Each panel profile will have different engineering values. For example, the load chart for corrugated is different than the load chart for a PBR panel. It is recommended that you have an engineer determine the appropriate span between metal purlins and the gauge of metal that will be used.

There Can Be A 40% Difference In Dent Resistance Between Thin And Thick 29 Gauges

In the metal industry, gauge is a range of thicknesses that manufacturers have to stay within. With profitability causing pressure on costs, many manufacturers are offering the thinnest metal that is allowed within the gauge. So, it is important that you understand the thickness of your metal so you can make an informed decision.

There can be a 40% difference in dent protection between the low and high end of 29 gauge. This difference in dent protection is an important consideration when investing in a metal roof.

Recommended Reading: Who Is The Best Roofing Company

Steel Shingle And Shake:

In Canada there is a wide range of steel roofing products designed for residential use. G90 is the accepted standard for roofing. G110 and G115 will perform better against acid rain or in marine environments. A high-end steel system will not need battens and strapping for installation, and panels will be interlocking . A galvanized steel roof with interlocking design and PVDF finish will have a better life expectancy than cheaper steel options. Coatings on a high-end steel system sometimes include reflective pigments to enhance energy efficiency. Keeping in mind that there is no steel roofing product that unconditionally guarantees against rust, cosmetic life is shorter than functional life.

Maintenance Required: Optional, re-paint to cover rust.Re-Roofing Cycles Over 50 Year Period: 1 if corroded through back of panel.Expect to Pay: $10.00 $13.00 CAD per square foot installed.

Example of a Shake Style Aluminum Roofing System. Other aluminum variations include shingle, slate and tile styles.

There May Be Quite A Few Reasons For Your Roofing Contractor Or Installer And Even Your Building Centre Sales Representative To Try And Discourage You From Installing A Metal Roof Even If You Are Convinced Of The Superior Qualities Of A Metal Roof And Are Willing To Invest The Money

Many of them are not used to selling the product and doing the necessary calculations to give you an accurate quote.

It is a little more work for them to give you a correct estimate for your type of roof, depending on roof pitch, shape, area to be covered, number of gables, dormers, skylights, valleys, trim and other features of your house.

They do not always know where to find reputable steel roof installers and the skilled tradesmen that will do a good job in their neck of the woods. Ideal Roofing representatives in the field know the right people to do the job right.

It may take longer and more precision to install a metal roof than it does to slap down and tack squares of asphalt shingles on any type of roof. Because the roofing season is so short in Canada and the Northeast United States, roofers want to finish their jobs as soon as they can to move on the next one and rack up more profits.

As with every business, roofers and building centres want to keep things simple and dont want to be bothered with orders and sales that are out of the ordinary, as they are intent on serving as many customers as they can in the least amount of time.

Roofers and building centres generally carry a large inventory of asphalt shingles normally purchased in springtime for consumption throughout the year. They prefer liquidating their inventory rather than ordering Wakefield Bridge steel shingles on a special order basis even if delivery may only take a few days.

You May Like: Is Tesla Selling Solar Roof Tiles

How Long Will A 29

The durability of a 29-gauge metal roof is probably the first thing you want to know. 29-gauge metal roofs last for around 25 years. They do not require heavy maintenance.

You should apply primer and coating every few years, but thats about it. Of course, if you find leakages, then you need to repair them as quickly as possible. Otherwise, it might end up spiraling into a bigger problem.Is a 29-Gauge Metal Roof Good?

There are so many metal gauges available in the market for roofing that it can be overwhelming. A popular question among first-time metal roof owners is whether a 29 gauge metal roof is good?

The simple answer is yes, it is very good. It has excellent durability, high energy efficiency, a good lifespan, and best of all it is economical.

You dont need very thick metal for the roof of your house unless you live in areas that receive extreme weather, such as regular cyclones or hurricanes. A 29-gauge metal roof provides more than enough protection for most homes.

Another thing you should keep in mind is that if youre living in a location that receives a lot of snowfall, its better not to use a 29-gauge metal roof. Its possible that with a thin metal roof that the weight of the ice might cause dents in your roof.

When To Choose A Thinner Metal Roofing Gauge

Span isnt always a concern in the residential market. Nearly all homes have a layer of plywood or oriented strand board sheathing covered by a weather-resistant barrier. The metal panels are affixed to the sheathing and serve no structural role in these instances their job is to keep the sheathing dry. A quality 29-gauge panel is more than adequate for thiswhich is why its used on nearly 80 percent of homes with metal panels.

Despite this, thicker panels can make sense for buildings in hail-prone areas, but not because of structural integrity. A 29-gauge metal panel can have the same impact-resistance rating from Underwriters Laboratory as a 26-gauge panel the advantage of thicker metal panels in this case is that they are less prone to denting. If your customer lives in a place like Cheyenne, Wyoming and is concerned about long-term appearance, thicker panels may be the better option.

Recommended Reading: How Much Should A New Roof Cost

How Will You Cut Your Metal Sheet With A Snip Tool

The aviation snips or tin snips have a spring to ease the pressure on your hand and are available in various colors. The handles of tin snips are either green, yellow, or red. You should select the color according to your desired cut for the metal sheets.

If you want to have a perfectly straight cut, then you should choose the yellow handle. Most house owners prefer to use a yellow handle snip to cut 29-gauge sheets.

When you want to trim the excess metal from the 29-gauge metal panel, you only need to use the right-hand and left-hand handles of the aviation snip. You need to use the red handle to trim the left side of your 29-gauge metal, and for the right side trimming, you can use the green handle.

You cannot use these right and left handle tin snips for trimming a large portion on your metal sheet. If you need to cut the large portion of a metal sheet and there is no alternative, start one and a half inches or two inches away from the mark to have a clean and straight cut. Try to avoid it if at all possible because trimming a large portion of the metal sheet with a tin snip can produce an uneven or rough edge.

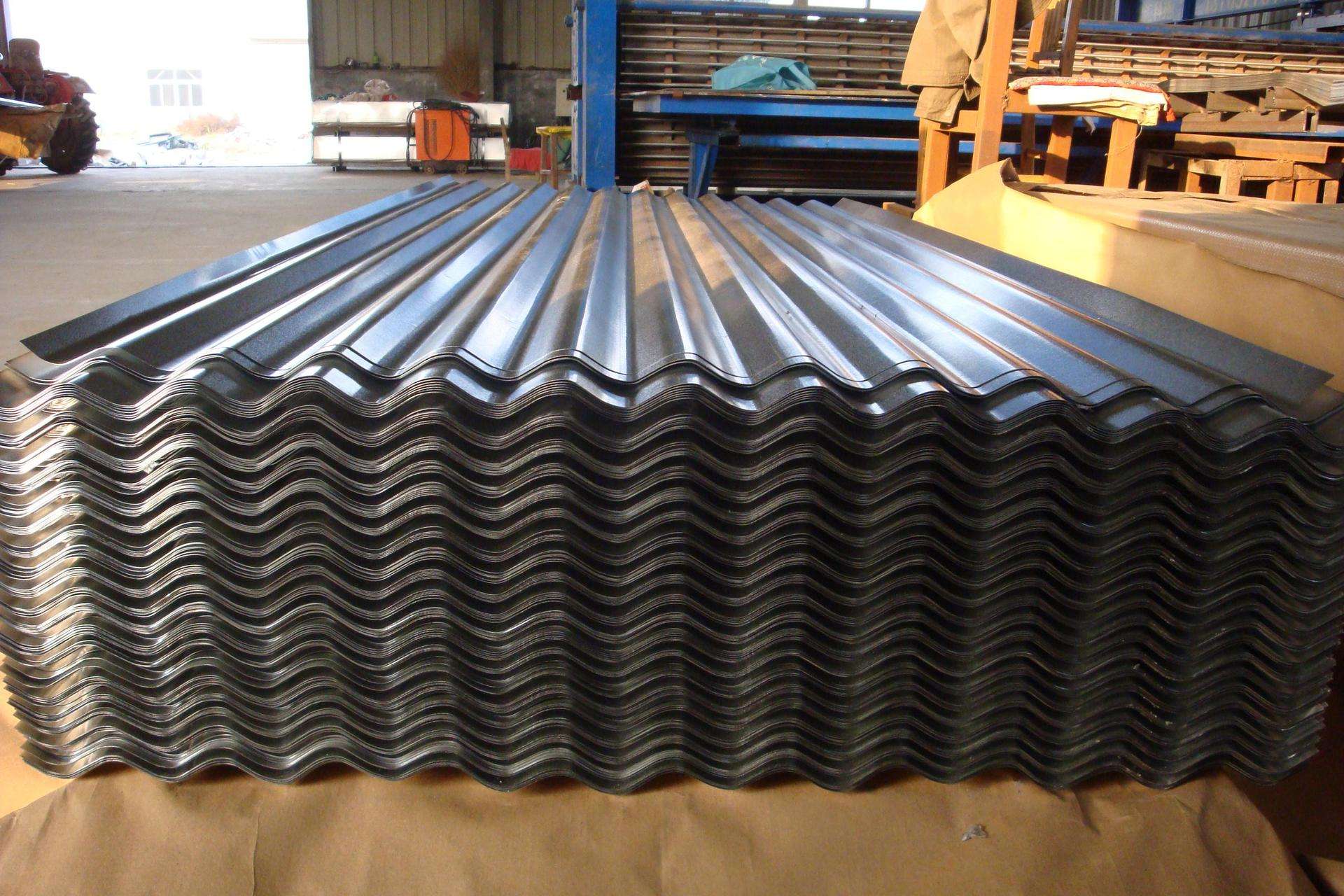

How To Cut Corrugated Metal With Tin Snips

You can also cut corrugated metal with the help of tin snips which, as Ive mentioned, are just like a pair of scissors. One should hold the snips in one hand, place its blade on the marking of corrugated metal, and cut it. Press the handle while cutting your sheet. This is a very easy method, and you will likely get a straight cut with tin snips.

Read Also: Why Is My Roof Leaking

What Are The Common Metal Roof Deck Gauges

Metal roof is manufactured in different profiles. Each profile will dictate what gauges are available to you. The gauges can also vary depending on the manufacturer. However on the West Coast you will typically find that for 1.5 Type B and 3 Type N, your options are: 22 Gauge, 20 Gauge, 18 Gauge and 16 Gauge.

1.5 Type B is a short to medium span panel and you will find that it is available in 22, 20, 18 & 16 gauge.

For 3 Type N, which is a deeper panel that can span longer distances, 22 Gauge is not a common gauge. The more common gauges for 3 Type N metal deck are 20, 18 and 16 gauge. Type N is used when a stronger panel is needed, which is why the heavier gauges are normally specified.

Buy Manufacturer Direct And Save Money On Your Metal Roofing Panels

We recommend that you get a quote from more than one company. You want a company that has great and a fair price. Our online form is quick and easy to fill out. Let us provide you a free quote.

When you buy metal roofing from Western States Metal Roofing you are purchasing directly from the manufacturer. Buying directly from the metal supplier can save you 15% to 50%. Our company offers inexpensive delivery throughout the entire country. Give us a chance to earn your trust and provide excellent customer service. Look at out our google reviews and give us a call at 877-787-5467.

Start the process of picking out your panels by requesting a quote.

Read Also: Will A New Roof Lower My Home Insurance

How Skilled Is The Installer

Installing metal roofing or siding by yourself is a reasonable undertaking.

For those who arent experienced with metal siding or roofing, choosing a heavier gauge may be a better decision.

The heavier gauges are more forgiving when it comes to common mistakes like over-tightening screws that can cause bumps and waves. Heavier panels tend to fit together more accurately, too.

Opt for professional installation if youre using thinner panels.

Ideal Roofings Metal Roofing Products Are The Perfect Roofing Solution For Our Extreme Northern Winters

Whether we want to admit it or not, the last few winters have been singularly unpredictable in Canada and the United States. From the West Coast to the East Coast, from the Prairies to the Atlantic Coast, and from the Great White North to the Great Lakes, the weather has been playing havoc with our traditional winters. Heavy snowfalls where there were few before, repetitious winter storms dumping tons of snow for several days at a time, extreme and prolonged cold snaps in Southern Canada and the American Midwest, followed by strong winds, mild weather up North, melting permafrost dangerously threatening our polar bears and caribou and generally creating hardship for everyone are now common occurrences.

These extreme weather conditions and variations in winter temperatures combine with extreme hot summer peaks, blistering sun, sudden high gusts of winds and heavy flash downpours causing flooding and sewer backups and water infiltrations subjecting roofs to water infiltrations and blown-off shingles.

Only the protection of a new steel shingled roof can resist these extreme weather conditions. A quality Ideal Roofing metal roof is your barrier against all weather-related aggressions. Steel panels and shingles are much lighter and and more resistant than asphalt shingles, concrete and clay tiles, cedar shakes and slate roofing materials, and stronger than aluminum shingles.

You May Like: How To Install Metal Roofing Over Asphalt Shingles

More Profile Choices Mean Westman Offers Better Steel Solutions

Whether for Agricultural, Commercial, or Residential building projects, our extensive line of 18 premium steel cladding profiles for wall, roof and wall applications enables our customers to turn their creative visions into reality. Ranging from traditional to contemporary, WESTMAN STEEL panels offer a wide variety of profile styles for an array of applications. Profiles are available in a palette of 30+ designer colours to perfectly customize and complement the aesthetics of any building project.

Select Tools To Cut Your Metal Sheet

There are multiple tools to cut 29-gauge metal roofing like tin snips, circular saw or nibbler,power shears, and angle grinders. Most people are comfortable with tin snips/aviation snips. They are easy to use. The tin snips are similar to scissors. You can operate them with one hand. Its not tricky, but you need to be mindful while cutting with tin snips.

You May Like: How Much Is A Tile Roof In Florida

Quality And Selection: The Cornerstones For Better Buildings

For almost 40 years, WESTMAN STEEL INDUSTRIES has been a leading Canadian manufacturer of innovative, premium-quality steel product solutions and services for Agricultural, Commercial and Residential applications. As a single-source supplier, WESTMANs unyielding commitment to providing a wider range of extraordinary building products durable steel panels in a variety of distinct profiles for roofing and cladding, doors and all required accessories makes it easier for customers to design and construct highly efficient, distinctive buildings that easily meet or exceed their needs, both in form and function.

What Is The Difference Between 24 And 26 Gauge Metal Roofing

Selecting the right gauge metal for your roof means considering a lot of factors. Is your building permanent or semi-permanent? What kind of weather do you have in this location? These are just a couple of examples, but a lot of consideration must go into your choice if you want to keep costs down while still ensuring that your structure is protected.

Today well compare 24 and 26 gauge steel roof panels to get an idea of what you may expect from each. Well compare protection, costs, and more so that in the end, youll be able to select the most cost-effective paneling that will give you exactly what you need.

Lets discuss 24 and 26 gauge metal roofs!

The biggest difference in 24 vs 26 gauge metal roofing will be the thickness of the metal. 24 gauge metal roofing is thicker, heavier, and more impact resistant than the thinner 26 gauge.

This means that your 24 gauge steel is the more durable roofing choice, especially where inclement weather is concerned. It will outperform the lighter 26 gauge when protecting from wind, the weight of snow, and potential impact damage from hail.

Read Also: How To Install Solar Panels On Tile Roof

Gauge Metal Roofing Vs 26 Gauge Metal Roofing

When the metal roofing sits on a solid wood substrate a 26 gauge material is appropriate and a good value. However, there are instances in which a 24 gauge material would be a better choice. If you live in an area with high winds and a lot of snow than spending the additional money on 24 gauge would make sense. In addition, if you want a PVDF paint then you will nearly certainly need to purchase a 24 gauge steel.

Metal roofing in a 24 gauge steel will weigh approximately thirty percent more than 26 gauge steel. As a result there is normally about a thirty percent price difference. That price difference will be even greater if you choose both 24 gauge and PVDF paint. An average size roof of 25 squares will cost between 10K and 20K installed, but the cost savings of using 26 gauge instead of 24 gauge is only $1,000-1,500.

If you are installing an exposed fastener panel then you will normally have a lot of options. You can choose 24 gauge in PVDF or numerous gauges in SMP paint systems. If you are installing standing seam panels then you are limited to 24 gauge PVDF.