Occupied Roof Egress Requirements

Egress to occupied roofs must be through a stairway which meets all the requirements of IBC stairway design. Additionally, the stairway to a roof must be through a penthouse complying with IBC section 1510.2. With these requirements, stairway access to occupied roofs will typically be an extension of the exit stairways up to the roof.

Do I Need A Railing For My Roof Hatch

Would you like to exit this roof hatch without a railing? This picture is not a fake. It was sent to us by one of our customers. It is a shame to say it, but sometimes safety is not the number one priority when a building is being designed and constructed. Whoever installed this roof hatch was clearly not thinking about the implications of their installation.

How Big Does A Roof Hatch Need To Be

Typically commercial buildings require rooftop access to maintain and check-up on HVAC or other types of equipment. Although there are several alternatives to accessing roof areas, the most common way is to use roof hatches. But before that, let’s discuss the importance of a roof hatch.

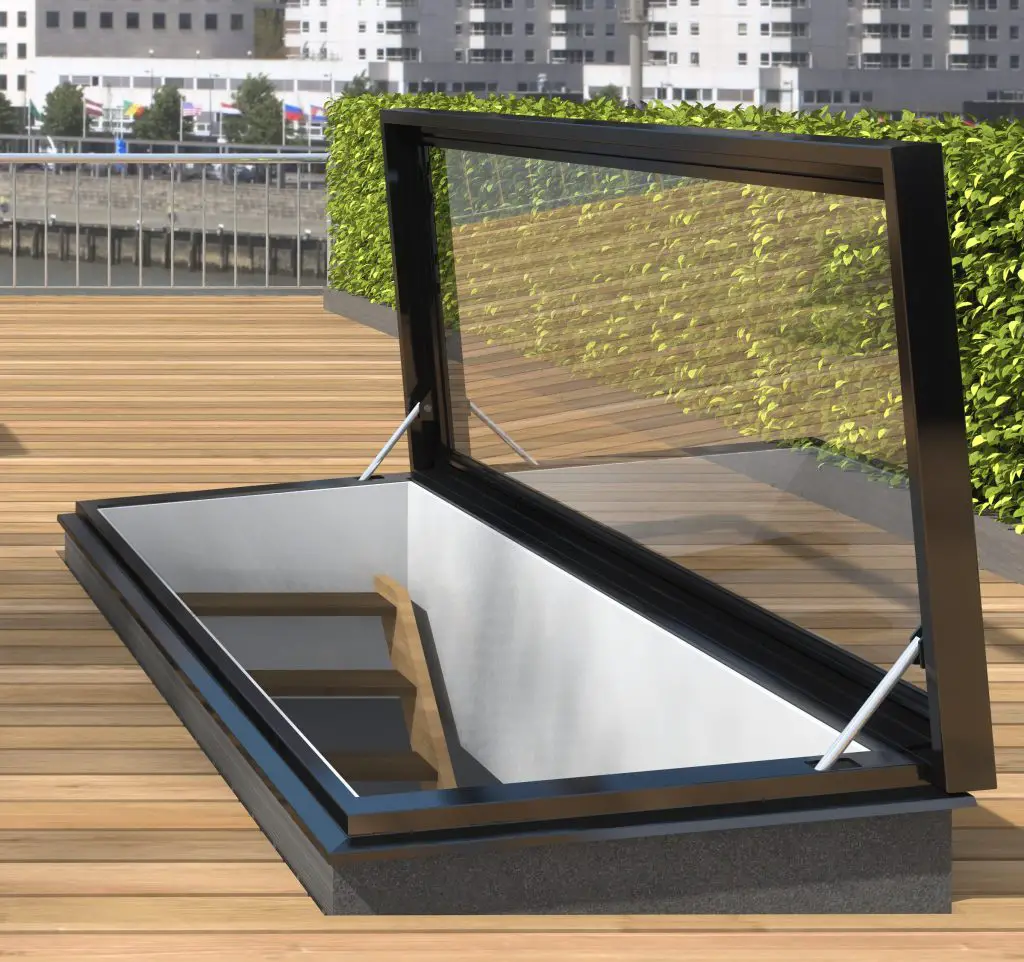

What is a Roof Hatch?

Roof hatches, manufactured with many features and options such as weatherproof performance, ensure safe access for your maintenance team. It is essential to know about basic roof hatch specifications, including hatch selection considerations and the various options available when working with roof hatches.

In addition, you should familiarize the Occupational Safety and Health Administration’s fall-protection regulations for roof openings that pertain to roof hatches. The 29 CFR 1910.23 notes that “Guarding floor and wall openings and holes,” as well as other safety options and penalties for noncompliance, is necessary to keep workers safe on job sites.

Before choosing the best roof hatch for your building, you first need to determine what type of material you want your roof hatch to be.

Roof Hatch Material of Choice

An important factor when choosing a roof hatch is its material. Usually, this decision will be solely based on the product’s aesthetic, costs, maintenance, and the hatch’s geographic location. Manufacturers can create galvanized steel, stainless steel, aluminum, and copper hatches.

What’s the Right Size?

Industry-Standard Sizes of Roof Hatch

Recommended Reading: Shingling A Shed

The Gorter Roof Hatch Combinations

With a Gorter combination, you have a total solution for roof access from the top storey of a building. A Gorter combination consists of a roof hatch with matching scissor stair, ladder or fixed staircase. The roof hatch and accompanying ladder/stair are designed to suit each other completely. The combinations are also TÜV NORD-certified and you can back up your RIE with the documentation supplied.

Roof Hatch Rht In Standard Sizes

- RHT7090: 700 x 900 mm / 38 kg

-

RHT7010: 700 x 1000 mm / 52 kg

- RHT9090: 900 x 900 mm / 44 kg

- RHT7014: 700 x 1400 mm / 52 kg

- RHT1010: 1000 x 1000 mm / 50 kg

- RHT1015: 1000 x 1500 mm / 65 kg

- RHT1020: 1000 x 2000 mm / 82 kg

- RHT9024: 900 x 2400 mm / 89 kg

- Thermal separated and insulated aluminium construction

- Counterbalancing system for assisted opening and controlled closing

- Wind and weather tight sealing between lid and curb

- Lid that engages automatically in open position, with one hand release

- Eurocylinder lock with 3 keys, inside and outside operation.

- Opening > 1501 mm with 3-point lock.

- Diagonal handrail on inside lid to safely enter and leave roof hatch

CodeMark certified for Australia & New Zealand

- Australia CM70087, New Zealand CM70088

Performance according to CE :

- Resistance to permanent loads : 1050 kg/m²

- Sound reduction : 26 dB

- Watertightness : Class E 650

- Resistance to wind load : Class E 3000

- Resistance to snow loads : 3.97kN/m²

- Impact hard body : Class P5A

- Impact soft body : Class 5

- Air permeability : Class 3

Powder coated in RAL7047 and RAL9010 .

| Copy to clipboard |

Also Check: How Do You Know If Your Roof Is Leaking

When Do You Need A Roof Access Hatch

There are a number of situations where you can use a roof access hatch, which you can generally sort into two categories:

- Non-residential buildings such as hospitals, offices, industrial units, etc.

- Residential buildings

Roof access hatches for non-residential buildings

Roof access hatches for non-residential buildings are often installed for the purpose of performing maintenance on the roof or rooftop installations, such as air treatment systems, air conditioning units, etc, which requires access to the roof. Until a few years ago, caged ladders were used to access roofs, meaning that people had to embark on a long vertical climb from the ground floor to the roof. The long climb and limited space in the cage did not make for an ideal way to access roofs. Additionally, unauthorized persons also used the caged ladders, which resulted in a number of risks.The big advantage of a roof access hatch is that you only need to bridge one floor. By installing a roof access hatch, the climb to the roof is moved indoors and you can use the existing staircase to reach the top floor of the building. The climb from the top floor and through the roof access hatch is then generally only 2.5 to 3 metres and you can easily and safely bridge this height by combining a roof access hatch with a ladder or staircase.

Roof access hatches for residential buildings

Unoccupied Roof Egress Requirements

For unoccupied roofs, under the exception to IBC 1011.12, access to the roof from the top story is permitted to be by an alternating tread device, a ships ladder, or a permanent ladder.

Also, the exception to IBC 1011.12.2 allows access to unoccupied roofs to be a roof hatch or trap door. So for unoccupied roofs, a ladder or alternating tread stair extending through a roof hatch is the most common method of accessing the roof.

Recommended Reading: Mobile Home Ceiling Panels Sagging

Occupational Safety And Health Administration

- Standard Number: 1910.23

NOTICE:

OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. This letter constitutes OSHA’s interpretation of the requirements discussed. Note that our enforcement guidance may be affected by changes to OSHA rules. Also, from time to time we update our guidance in response to new information. To keep apprised of such developments, you can consult OSHA’s website at .

Mount Laurel, New Jersey 08054

Dear Mr. Swindell:

Thank you for your November 12, 1999 letter to the Occupational Safety and Health Administration’s . You have questions regarding Roof Access Hatches and Fixed Ladders. We apologize for the delay in our response.

Question 1: Is it necessary for a roof access hatch equipped with a fixed ladder and a hatch cover to have a device to grab onto to exit and enter the hatchway?

Question 2: If so, does the grab device in question #1 above have to extend 36 inches or greater above the roof line?

Question 3: Is it necessary to protect the opening if the cover is left up while personnel are on the roof?

Sincerely,

Flat Roof Metal Hatch Drl

The Flat Roof Metal Hatch is an insulated metal hatch for accessing a flat roof. It can be combined with the LML wide-step metal attic ladder or any FAKRO attic ladder for ease of access. The piston-assisted hatch stays open at a 80-degree angle while anti-slip covers on the frame ensure safe footing.

Don’t Miss: How Much Shingle Roof Cost

Selecting The Proper Size Hatch

The angle at which a person ascends to the roof determines the size hatch required for convenient use. If a ladder is used, the hatch may be rather small since the person comes straight up to the roof. As the angle of ascent decreases, the hatch must be larger to prevent head-bumping accidents. Recommended minimum sizes for various types of roof access are shown above. If movement of bulky materials through the hatch is anticipated, double-leaf hatches with openings up to 66 sq. ft. or larger are available. Recent changes to the International Building Code require 16 sq. ft openings as the standard for various structures.Note-the second dimension on hatch sizes denotes the length on the hinge side.

Roof Hatches In Aluminium Or Steel

All standard Gorter roof hatches are manufactured from high-grade aluminium. This makes the construction strong, durable and not particularly cumbersome. Aluminium roof hatches are up to three times lighter than comparable steel roof hatches. This makes the hatches easy to lift and they can be installed on the roof without much equipment. The special fire-resistant versions are manufactured from steel based on the characteristics required.

Read Also: Tesla Solar Roof Cost Per Square Foot

How Do You Make A 2d Roof In Autocad

1. Draw a closed 2D polyline in the shape of the intended roof, in the location where you want to place the roof.

2. Open the tool palette that contains the roof tool you want to use.

3. Right-click a roof tool, and click Apply Tool Properties to Linework and Walls.

4. Select the polyline to convert, and press Enter.

Osha Roof Access Requirements

OSHA roof access requirements apply to all stairs and ladders used for equipment or maintenance access that are not used as a means of egress.

Access devices for these applications will fall under the International Mechanical Code rules for equipment on roofs or the OSHA design standards for stairs and ladders. OSHA has many requirements for ladder and stair design but only two general requirements for how stairs and ladders should be applied in different situations. These are as follows:

- 1910.23 Ladders are used only for the purposes for which they were designed

- 1910.25 Spiral, ship, or alternating tread-type stairs are used only when the employer can demonstrate that it is not feasible to provide standard stairs.

OSHA leaves it up to the employer to ensure that the use of a stair or ladder device is safe and appropriate in each application, so employers must understand the safety, feasibility, and usability of stairs and ladders in different applications.

OSHA roof access ladder requirements

OSHA regulations for roof ladders are found in OSHA 1910.23 – Ladders.

Permanent roof ladders for regular maintenance use are defined by OSHA as fixed ladders:

Fixed ladder means a ladder with rails or individual rungs that is permanently attached to a structure, building, or equipment. Fixed ladders include individual-rung ladders, but not ship stairs, step bolts, or manhole steps.

OSHA defines three different types of fixed ladders that may be used for permanent roof access:

You May Like: How Much Does A Roof Cost In California

Why Are Thatched Roofs Good

Thatch roofs are known for being great at keeping water out of your home or building. Thatch roofing materials are naturally waterproof so they wont become waterlogged and seep into your interior, and theyre piled on top of each other so that it becomes impenetrable to rain and other elements.28 fév. 2014

How Do I Find The Hatch Area

Now exit hatch command and select hatch created in area B then right click and select properties from the contextual menu. A property palette will appear, scroll down in the palette and locate geometries panel there you will see Area of the hatch. This hatch area will also be the area of enclosed geometry.20 fév. 2020

You May Like: Replacing Roof Trusses

Ontario Building Code Requirements

Below are included some of the building code requirements that relate to roof access. Its worth noting that the Ontario building code is constantly being updated, so its important to stay on top of the changing regulations. Ontario building code – attic accessThe Ontario building code regulations state that an attic space that is higher than 600 mm must have access from the floor immediately below by either a safe stairway or by a hatch no smaller than 550 mm by 900 mm.

More About This Product

RHT Gorter roof hatches provide safe roof access combined with exceptional insulation. The RHT roof hatches have a full thermally broken curb and cover and a proven high insulation value. This minimises the chance of condensation forming and provides energy-cost savings. The roof hatch construction is also soundproof and burglary-resistant.

Gorter roof hatches can be used as escape hatches, but in most situations, they provide practical and safe access to flat roofs for maintenance work or to a roof terrace. Roof hatches can be installed on flat roofs with a maximum slope of 30°.

Benefits:

- TÜV NORD & KOMO® certified and Aboma safety mark

- Fully thermally broken curb and cover

- Safe to operate with one hand

- 10-year warranty on the roof hatch

- Optional electric control

- High-quality aluminium construction, 3x lighter than steel, strong and corrosion-free

- Euro cylinder lock with indoor and outdoor operation

- Burglar and soundproof

Recommended Reading: Exposed Fastener Metal Roof Screw Pattern

Roof Access With The Gorter Translucent Roof Hatch

All Gorter translucent roof hatches have a cover which is completely windproof and has all-round double sealing. The translucent roof hatch is opened and closed by two powerful and compact electric motors.

Translucent and standard in aluminium

The Gorter translucent roof hatches are manufactured from high-grade aluminium. This makes the construction strong and durable. The roof hatch also has a durable powder coating inside and outside to keep maintenance to a minimum.

Roof Access With The Gorter Roof Hatch

All Gorter roof hatches have a cover which is completely windproof and has all-round double sealing. The RHT roof hatch comes with a Euro cylinder lock and, in the case of lengths over 1,400 mm, the roof hatch also has three-point locking.

Standard for all roof hatches

All Gorter roof hatches are fitted as standard with a number of convenient and safety-enhancing fittings. For instance, there are easy opening features with a counterbalancing system and controlled closing. The roof hatch has automatic blocking in an open position and is always safe and easy to use with one hand.

Read Also: Cost Of New Roof California

Roof Access Hatch: What Are The Standards To Comply With

A roof access hatch is a protective device that helps prevent the risks of falling from a height, off a roof. In addition, a roof access hatch is both a way to access the roof and a significant physical barrier that lets you create a real boundary when faced with the potentially dangerous situation that the height represents.

What Is A Roof Hatch Used For

Roof hatches are also used as escape hatches. However, in most cases, they provide easy access to rooftop facilities such as cooling rooms, lift machine rooms and window cleaning, solar panels, and other rooftop facilities. Roof hatches are suitable for flat roofs that have a pitch greater than 30deg.

Recommended Reading: Roof Replacement Cost In California

Gorter Electrical Operation Of Roof Hatches And Floor Doors

Standard Electrical operation – GT35

The Gorter GT35 electrical operation is a solution, which can be fitted on any standard Gorter RHT roof hatch or floor door of the type WA, WAPT and OP. The two powerful electric motors are always fitted as a pair on both sides of the lid. The motors are pre-fitted from the factory or can be fitted afterwards on any standard RHT roof hatch from model year2012 and later.

- Roof hatches type RHT standard

- Hinged Floor doors type WA , WAPT and OP

Operation and control 230Vac

The Gorter GT35 is a system with two motors and a control unit. The system comes standard with a wireless remote control and a compact control panel. The keypad connected with signal cable can be installed remote from control unit.

Dimensions:

Control unit: 265 x 105 x 40 mm

Keypad: +/- 70 x 50 x 10 mm

Length of signal/power cable motors: 2 m

Electrical installation:

The drives and the wiring must be installed by a certified installer

Operation for a hatch with double lids

Depending on the access door type, the weight of the cover and the application, we can install one or more gear rack drives. These drives are available in 24 Vdc or 230 Vac.Operation and control 230Vac

This is the simplest system with 1 motor. It can be operated with an integrated or surface-mounted switch, not included.Operation and control 24VdcOperation of one or more drives is controlled by a control box with rectifier that is connected to the electricity network. Features

What Type Of Roof Hatch Does Fakro Carry

FAKROs DRL is most similar to a standard roof hatch yet differentiates itself by its aesthetic appearance and an easy lock bar.

The easy lock bar facilitates roof access, especially for maintenance workers already heading up to the roof with tools in their hand. The lock bar is installed towards the front of the lid and is locked by a simple pull towards the body.

To reopen the hatch the bar is push away from the person and the gas pistons safely lift the lid to 80 degrees. DRL comes with the option to add an additional key lock.

When combined with the FAKRO LML ladder the user then makes getting onto the top of the roof safer due to the ladders additional step located in the frame of the hatch. The user no longer has to swing her/her foot over the frame.

The real crowd pleaser is FAKROs DRF DU6. While its use the same as FAKROs DRL, the DRF DU6 brings light to the room below. This gives users the chance to access the roof and bring light into the dark space below.

The FAKROs DRF DU6 Roof Hatches is also suitable for green roofs above residential buildings. With its aesthetically pleasing appearance it also is one of the safest roof hatches FAKRO has to offer.

The lock bar is similar to the DRL and its energy-efficient DU6 glazing with UV filtering double chamber Low-E glass filled with argon gas, makes it one of the best roof hatches for commercial and residential buildings. This product is the only one like it on the market!

Also Check: Shingling A Shed Roof