What Is The Screw Pattern For Corrugated Metal Roofing

The screw placement for corrugated can be a little tricky. The fasteners are located in different locations for roofing and metal siding conditions. Then if that wasnt confusing enough metal roofing manufacturers have differing opinions on the correct corrugated screw placement for a roofing condition. Hang in there and we will explain this one to you in detail.

Just in case you are a visual learner we created this easy step by step video also.

There are two schools of thought when it comes to corrugated metal roofing screw placement. Both are correct.

If the fastener is placed in the low of the panel it partially obstructs water and debris. The low of the panel is skinny and the fastener takes up most of that space. As the water drains it will go over the screw. Screws that have backed out over time or that were installed incorrectly will leak. You will avoid the bulk of this issue by installing the fastener in the high of the roofing panel.

S To Estimate Metal Roofing

Measure the length and width of each roof section in feet, then multiply together to get the square footage.

If you are unable to crawl on the roof, you can estimate by measuring the roofs footprint and finding its square footage. Multiply the footprint square footage by the multiplier for your roof pitch to find the actual square footage of the roof. Use our roof pitch calculator to find the pitch of your roof.

Next, find the square footage of the metal roofing panels you want to use. Measure the length and width in feet, then multiply together to find the square footage. Panels are often measured in inches, so you can use our inches to feet conversion calculator to convert to feet.

Finally, divide the square footage of the roof by the square footage of the metal roofing panel to find the number of panels needed for your roof. Its a good idea to order an extra 10% to account for cutoffs and waste material.

For more complex roofs with many peaks and sections, find the square footage of each roof section and add them all together to find the total square footage. Consider ordering a few extra panels to account for more cuts and waste.

How Often You Screw Down A Metal Roof

Figuring out how the correct distance from screw line to screw line is an easy process. It will depend upon whether the metal roofing is installed over a solid wood substrate or over metal purlins. Each of these conditions will lead to different distances between the screw lines. After you have your screw line spacing it will be simple to determine how many screws to purchase.

Also Check: House Trusses Cost

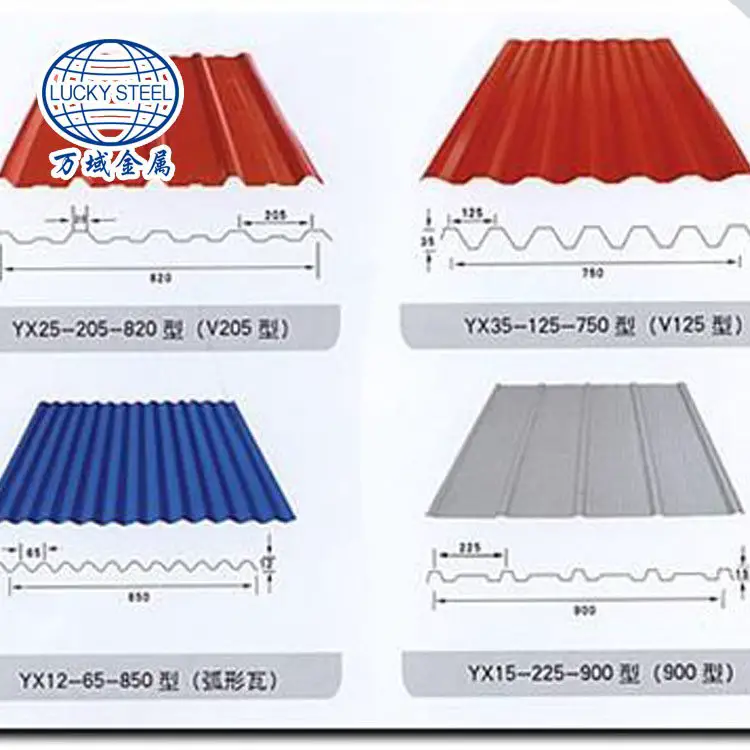

How Wide Is A Piece Of Metal Roofing

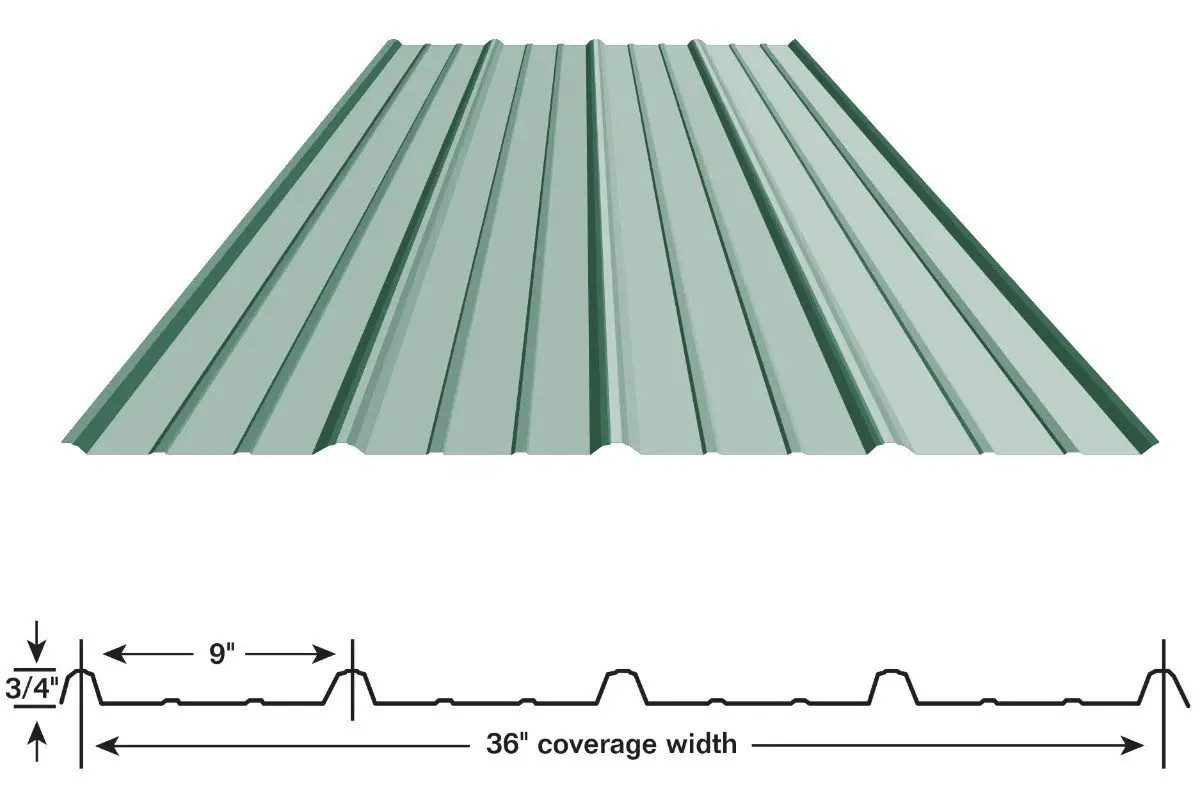

Metal roofing comes in 24 and 36-inch wide measurements. However, each of these widths also provides for 2-inch overlap on both sides. You can purchase metal roofing material in any length you need and have it cut to the appropriate length before you install it.

Similarly, you may ask, what is the standard width of metal roofing?

The two most common widths are 26 and 36 inches. Other standard widths include 24 and 39 inches. When calculating coverage using the width and length of corrugated roofing, keep in mind that each piece will need to overlap by several inches.

what is the width of corrugated iron? 850mm

Furthermore, how do you measure for metal roofing?

Divide the length of your roof by the width of the metal. In our example we will use 24-inch standing seam roofing, so we will divide 360 inches by 24, which equals 15. This is the number of metal panels needed for one side of the roof.

How wide is colorbond roofing?

762mm is the cover width which allows for 1.5 rib overlap. The actual single sheet width of the corrugated sheet is 850mm wide.

Which Is Better: Steel Or Aluminum Roofing

Neither type is better than the other its all about your preferences. However, if youre trying to choose between steel and aluminum roofing, do as much research as possible before you make your decision. In the previous sections, you can read about the pros, cons, and costs compared to the other types.

To make the most informed decision, contact your local roofing experts to schedule a consultation. Our team at Legacy Service will guide you throughout the process, from helping you determine the best choice during the inital consultation to communicating with you every step of the way if you decide to go through with the project.

Also Check: How Do You Know If Your Roof Is Leaking

More Resources On Metal Roofing Installation

Screw placement for metal roofing and siding panels is easy. After you view the videos and diagrams in this article you will not have any issues. If you are learning about screw placement then the next steps is to learn more about fastening the metal sheeting and trim and flashing installation. An excellent starting point would be to view our installation guides or watch our installation videos.

The first piece of trim that will be installed on your metal roof is the eave trim.

We created an EASY step by step installation video to make your metal roofing installation as simple as possible.

Discover which type of fastener is right for your metal roof installation by reading:

Can Skylights Be Installed On A Metal Roof

Yes! Almost any kind of roof can have skylights installed, including metal. However, there are a few things to keep in mind if you choose to install them:

- Think about when you want the skylights installed. Its much easier to add skylights while installing or replacing your roof rather than on a roof thats already in place.

- While you can prevent a metal roof from being noisy when it rains, its more difficult to soundproof a skylight. If your area tends to get plenty of rain, you might want to skip the skylight.

- Skylights can impact your buildings energy efficiency since it can alter the heat entering and escaping your home.

Recommended Reading: Best Placement For Screws In Metal Roofing

The Cost Of A Metal Roof

Youll have two metal roof options to choose between, a standing seam metal roof and a screw-down metal panel roof. Just like the different types of asphalt shingles, they both have different price points.

A new screw-down panel metal roof costs around $4.50 per square foot to start.

On the other hand, you can expect a new 24 gauge steel standing seam metal roof to cost around $12.00 per square foot for a one-story house with a basic up and over roof with no penetrations and no valleys.

For a more complex roof on a one-story home, you can expect a new 24 gauge steel standing seam metal roof to cost around $15.00 per square foot.

If youre seriously considering a metal roof for a residential home, I strongly recommend a standing seam metal roof to ensure you get the most out of your investment.

Calculate The Number Of Metal Panels

You must be wondering now how many metal sheets do I need for my roof. You need to divide the length of one side of the roof with the width of the metal sheet. In our case, the length of the roof is 21 feet, and the Width of the panel is 26 inches or 2.1 feet.

Now divide 21 by 2.1 which comes out to 10. You will therefore require ten panels for your roof. You have a calculation for one side of your roof, so repeat the procedure to find out how many panels you need for the other side. The number should be almost identical.

In our example, the total number of panels needed is ten, and the length of each panel should be 254 inches.

Recommended Reading: Where Do You Put Screws In Metal Roofing

You Should Use 26 Gauge Metal Panels If:

- The panels are being installed in a climate with extreme weather conditions .

- Longevity is a top priority and you want panels that will last longer.

- Appearance is a top priority and you want a product with greater resistance to dents.

- You are building an open frame structure, such as a pole barn. While 29-gauge can be used for the walls of small barns, 26-gauge is advised for the roof and walls of larger barns.

Steel Shingle And Shake:

In Canada there is a wide range of steel roofing products designed for residential use. G90 is the accepted standard for roofing. G110 and G115 will perform better against acid rain or in marine environments. A high-end steel system will not need battens and strapping for installation, and panels will be interlocking . A galvanized steel roof with interlocking design and PVDF finish will have a better life expectancy than cheaper steel options. Coatings on a high-end steel system sometimes include reflective pigments to enhance energy efficiency. Keeping in mind that there is no steel roofing product that unconditionally guarantees against rust, cosmetic life is shorter than functional life.

Maintenance Required: Optional, re-paint to cover rust.Re-Roofing Cycles Over 50 Year Period: 1 if corroded through back of panel.Expect to Pay: $10.00 $13.00 CAD per square foot installed.

Example of a Shake Style Aluminum Roofing System. Other aluminum variations include shingle, slate and tile styles.

Don’t Miss: How Much Does A Roof Cost In California

Corrugated Screw Location For Wall Panels Or Metal Siding

There will be five panel screws and one lap screw per screw line. The lap screw is the screw that sits in the high and it is designed for a light gauge metal to light gauge metal connection. Lap screws are spaced 12 to 18 on center. The panel screws are spaced out so that every third corrugation has a screw including both sides of the panel sidelap. When the corrugated sheeting is 39 wideinstead of 37 wide the screw placement will be slightly different as shown in the diagram below.

We recommend that you use double sided mastic tapeat the panel sidelap for a wall condition also. The mastic tape will make the panel more weathertight. Mastic tape is always used for a metal roofing installation. On a wall application, mastic tape is shown in our installation guide and we do recommend that its used. The reality is many installers choose not to install the mastic tape for wall conditions.

What Is The Slope Range

Standing seam metal roofs can fall into two categories: Low slope and steep slope . The higher the pitch, the faster it is for water and snow to drain off.

With low-sloped roofs, a hydrostatic system is necessary to ensure the building remains watertight. Standard slope pitches can range from 1:12 to 18:12. But the minimum slope requirement for standing seam metal roofs is ¼:12.

Also Check: Skylight In Metal Roof

How Do I Verify Measurements For My Metal Roof

Are you a do it yourself person or a contractor thats familiar with shingles but new to metal roofing? If thats you, or if you just want to answer the question How do I verify measurements for my metal roof then this vlog post is definitely for you!When it comes to figuring materials for your roof it all starts with a sketch. And over the years Ive seen all sorts of sketches. Ive seen them range from a doodle on a napkin to full-blown architectural drawings.

How Do You Measure Sheet Metal Thickness

You can find the thickness of your sheet metal by using a measuring tape and a simple conversion technique. First, use the tape measure to find its thickness in millimeters. This helps get the most accurate measurement. Second, multiply the number of millimeters by 0.03937. If your original measurement was 40 millimeters, the new one would be 1.5748 in inches.

Also Check: Exposed Fastener Metal Roof Screw Pattern

Everything About Standing Seam Metal Roof Types: Profiles Dimensions Materials And More

There are many types of standing seam metal roofs. These vary in profile, size, material, price, and color. The choice you make will affect the overall cost, durability, and the amount of labor required during installation.

That’s why it is essential to learn about the different types of standing seam metal roofs available and their applications.

Having a variety of options for the consumer is a great selling point. However, it is easy to get lost when there are multiple variations to consider. In this article, we examine the different types of standing seam metal roofs available on the market. We also tell you how to choose the most suitable one for you.

Do You Pre Drill Metal Roofing

More on how to install metal roofing: On exposed fastener panels: While you are not required to, consider pre-drilling holes for your screws. Pre-drilling panels will make it easier to get the screw lines straighter. Otherwise, they will cause unsightly rust spots where they rest on the metal roofing.

Read Also: Briarwood Pro Shingles

What Sizes Are Standing Seam Metal Roof Panels

Apart from the different profiles, standing seam metal roofs also come in varying sizes. Due to their unique installation methods, the panels usually feature custom sizes, either roll-formed beforehand or on-site. The size you choose will depend on the type of profile, performance requirements, and personal preferences.

Less Qualified Contractors Have Experience Installing Standing Seam Roofing

Finding a contractor who is qualified, skilled, and experienced in metal roof installation is vitally important, especially because standing seam systems require careful craftsmanship. Since standing seam installations may be considered too complicated or tedious, there are far fewer contractors to choose from who have a proven track record and the relevant experience.

Recommended Reading: Replacing Roof Trusses

Trim For Corrugated Metal

If you’re learning about how to screw down a metal roof then there’s a good chance you will need help installing the corrugated metal trim or the corrugated metal panels. Our easy to navigate Metal Roofing Learning Center has step by step installation videos for all of your corrugated trim installation details.

More Options For Standing Seam Systems

Striations or Stiffening Ribs

Striations, also called stiffening ribs or rib rollers, are the patterns rollformed into a metal roofing panel between the seams. These can be used to assist with the installation of a metal roof, to help reduce the visibility of oil canning, or just for curb appeal. In fact, we recommend using striations in standing seam panels, some available options include:

- Flat No indents between the seams

- Striated Small consistent indentation lines in the panel

- Ribbed Shapes or indentations between the seams

- Pencil Circular panel indents

- V-Ribs V shaped panel indents

- Bead Longer, rectangular panel indents

Thicknesses

The metal coil that is rollformed into panels comes in many different thicknesses however, standing seam panels are typically somewhere between 22 and 26 gauge, with the most common Galvalume® thickness being 24 gauge and aluminum between .032 and .040 inches.

You May Like: How Far Apart Should Screws Be On Metal Roof

What Is Thicker: 24

When it comes to 24 vs. 26, 24-gauge is the thicker metal. Measuring gauge metal panels can be confusing because the lower the number is, the thicker the metal is. For our recommendation about which thickness would work best with your building, please feel free to contact us at any time to schedule an appointment with one of our techs.

Whats The Most Expensive Type Of Roofing Material For A Replacement

President at Bill Ragan Roofing Company

When choosing a roofing material for their replacement, a lot of homeowners look for affordability. This is understandable because a roof is a big investment.

But sometimes, whether its out of curiosity or genuine interest, some homeowners ask what the most expensive type of roofing material is. Because choosing the right roofing material is such a big decision, Ill answer that question and more.

For over 30 years, Bill Ragan Roofing has helped homeowners like you choose the right roofing material for their replacement. Now well help you determine if the most expensive roofing material fits your budget.

To start this article, well get right into what the most expensive type of roofing material is and how it costs. After that, youll learn the cost of 4 more popular residential roofing materials, so you can find the one that fits your budget.

And at the very end, we provide a guide with even more information to help you really determine which roofing material is right for you.

Don’t Miss: Proper Screw Placement Metal Roofing

What Is The Correct Screw Pattern And Spacing For R

The screw placement for R-Panelis straight forward. The screws are located in the same location for both metal roofing and metal siding applications. One item of importance is that you will have additional screws at the ends of the panels. This lessens the likelihood of strong winds ripping the panels off of your building.

There will be five panel screws and one lap screw per screw line at the panel ends. The remaining interior panels will have three panel screws and one lap screw at each screw line. Pay close attention to the diagram above in which the top left is circled. This is blown up larger and shown in the diagram as detail AA. You must attach a panel screw in this exact location. In addition, there are lap screws that are connected at 12 to 18 on center and butyl tape seal, which is the same thing as mastic tape.

The screw placement for 7.2 Panel and Western Rib is simple. Panel screws are located in every panel low. There will be five panel screws and one lap screw per screw line. Lap screws are connected at 12 to 18 on center and butyl tape seal is used at the panel sidelap.