What Are The Best Roofing Nails

Stainless steel nails are good for fastening tiles and slate. Galvanized roofing nails, or steel nails coated in zinc, are perfect for asphalt shingles, and they hold up well against rust. Aluminum nails should be used for surfaces made out of metal and siding.

Consequently, what nails are used for roofing?

Stainless steel nails are also good for fastening tiles and slate, or you can work with copper nails for standard roofing purposes. Galvanized roofing nails are steel nails that are zinc-coated. They hold up better against rust, and they can also be used for asphalt shingles.

Additionally, which is better roofing nails or staples? Fasteners for asphalt shingles should be roofing nails or staples. The head of a roofing nail or the crown of a staple is what actually holds a shingle in place. If staples are properly installed, they offer nearly the same wind resistance as nails. The problem with staples is the orientation of the staple crown.

Hereof, what size roofing nails should I use?

Proper Nail Application For Asphalt ShinglesNails should have a minimum, nominal shank diameter of 11- or 12-gauge, and a minimum head diameter of three-eighths of an inch. The length of each nail must be a minimum of 1¼ inches long, and for roof-overs, Atlas recommends a nail length of at least 2 inches.

Is it better to hand nail shingles?

You May Like Also

When To Choose A Screw Shank Nail

For roofs that are made up of wood and pallets, a screw shank nail is considered the best option, instead of relying on a hand driven nail. This is due to the twisted shank that is able to hold the timber more securely, meaning the roof structure will remain firmly in place, even during bad weather conditions.

Another main characteristic of a screw shank nail is the flat head that also features a diamond tip. This makes it easier to penetrate the roofing material, without creating any unnecessary issues, which is why many professionals opt to use screw shank nails for timber roofing projects.

How Long Should Roofing Nails Be

Choosing the right size of a roofing nail is important to ensure that a roof stays intact for a long time. Roofing jobs need to be done with proper planning to avoid nails coming off or extracting on their own over time.

Roofing nails should be 1-1/4 to 2 inches long to ensure that it sufficiently penetrates and embeds in the roof sheathing. To calculate the appropriate roofing nail length, add the thickness of the shingles and underlayment to the thickness of the sheathing.

Nail shank diameter should be at least 11-12 gauge for roofs.

Nails for roofs come in a range of varying sizes and lengths to secure roof tiles, metal sheets, or shingles on the roof in place.

The correct installation of roofing nails is important for a house because these installations determine how waterproof the roof would be and also to ensure the long term overall protection it will provide.

Don’t Miss: Skylight For Metal Roof

Where To Nail Shingles

Each shingle manufacturer has its own requirements forproper nailing, including where roofing nails should be placed. Roofingcontractors should follow those guidelines and take care not to overdrive nailsas this can lead to water infiltration.

Owens Corning® Duration® shingles, for example, provide a reinforced nailing zone, called SureNail® Technology a tough, engineered fabric strip embedded on the face of the shingle that offers outstanding nail pull-through and nail blow through resistance while providing a highly visible nailing target for roofing contractors. Its easy to see where the nails are supposed to go.

Can You Nail Siding Into Osb

When the correct fastening method is used, trim and siding can be directly attached to the nail -base structural sheathing. Thats true even if the siding is attached to plywood or OSB through a layer of non-structural continuous insulation.

Recommended Reading: How To Tell If Your Roof Is Leaking

Driving Roofing Nails For Shingles

Roofing nails should be driven by hand with a hammer or with a properly adjusted pneumatic nail gun.

Nail guns that are improperly adjusted can result in either under penetration or over-penetration of the roofing nails, which then affects the shingles performance. It can also cause:

- Nail corrosion

- Buckling, and

- Shingle blow-offs.

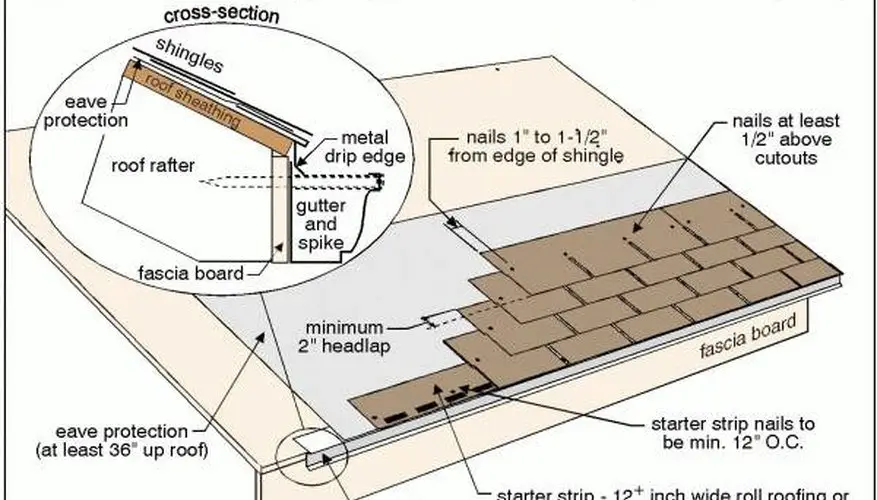

Roofing nails are typically placed no closer than 1 inch fromthe edge of the shingle according to the manufacturers specifications.

Fixing Nailing Mistakes

Its important that nailing errors are fixed immediately.

- Underdriven nails can be appropriately tapped in with a hammer.

- Crooked or overdriven nails need to be removed, and the holes need to be filled in with asphalt roofing cement.

- A new nail must be driven in a nearby spot to secure the shingle. If this cant be done, the entire shingle should be replaced.

Nail Fastening Pattern

A four-nail fastening pattern per shingle is required to take advantage of the maximum wind warranty available on Owens Corning® Duration® shingles. Six nails are required for structures with slopes exceeding 60 degrees or 21 inches per foot.

In some areas of the country, building codes may require six nails as well.

It is important to consult your local building department and to refer to the manufacturers installation instructions as the number of nails required often varies depending on the shingle product.

How Good Is Rolled Roofing

Rolled roofing is the least expensive roofing material, even compared to low-cost composite shingles. All materials, even the nails, are inexpensive. This product is the best way of covering low-incline roofs. Hammered-down rolled roofing should not be used on flat roofs, though, as this will lead to leaks.

You May Like: House Trusses Cost

Short Nails In Shingles

Have you ever noticed roofs with shingles popping up all over the place? A common reason for this is the use of nails that are too short. When there are popped nails all over the roof, it might be the sign of a defective roof installation specifically, short nails.

The minimum fastener length for an asphalt shingle roof in Minnesota is 1-1/4. This requirement comes from section R905.2.5 of the 2006 International Residential Code, which is part of the Minnesota State Building Code. I underlined the part of this section that specifies the minimum fastener length.

R905.2.5 Fasteners. Fasteners for asphalt shingles shall begalvanized steel, stainless steel, aluminum or copper roofingnails, minimum 12 gage shank witha minimum 3/8-inch diameter head, ASTM F 1667,of a length to penetrate through the roofing materials and aminimum of 3/4 inch into the roof sheathing. Wherethe roof sheathing is less than 3/4 inch thick, the fastenersshall penetrate through the sheathing. Fasteners shallcomply with ASTM F 1667.

In southern parts of the country where they dont need to deal with snow loads, its acceptable to use 3/8 roof sheathing, which means its also acceptable to use 1 roofing nails on asphalt shingles. A 1 nail will fully penetrate through 3/8 roof sheathing, but it wont fully penetrate 1/2 sheathing. The diagram below helps to illustrate this.

How Many Shingle Nails Do I Need To Buy

Quantity is just as important as quality and classification when it comes to roofing nails. If you dont have the proper number on location, then youre going to run into a problem towards the end of your project.

Nails per shingle

According to GAFs asphalt shingles guidelines, you must use secure with 4, 5, or 6 nails per shingle per GAFs application instructions or local codes, however, most of GAFs shingle lines require 6 nails per shingle.

You should use 6 nails per asphalt shingle to properly adhere all materials to the roof surface. The six nail requirement is especially important for high wind shingle application areas where a 5 nail per shingle pattern would not be sufficient.

Nails per roofing square

One square of roofing is about 100 square feet of roof material, and one bundle of shingles covers about of a roofing square. With this being said, youll need three bundles of shingles per square.

Each shingle bundle will contain about 28 shingles, so you can expect to have 84 shingles per square in total.

How many roofing nails per square? When using a 6 nail strategy during roof installation, youll need an average of 506 nails per square. Dont hold yourself to this exact count because every brand is different, but this math can be used as a guide for your planning.

You May Like: Roofing Cost Los Angeles

What Size Roof Sheathing Should I Use

Roof sheathing comes in grid-marked 4-by-8-foot sheets, and should be installed perpendicular to the frame. Sheathing should be a minimum of 19/32-inch thick. Never attach roof sheathing with staples 8d ring-shank nails should be used instead. The typical thickness range for sheathing is 3/8 to 3/4 inch.

What kind of wood is used for roof sheathing?

plywood

Choosing Nails For A Roof: Your Best Options

If you are starting a roofing project, you have an important question to answer: staples or nails? Heres a hint the correct answer is nails, but you must still choose the best nails for a roof project. Here is the information you need to get started:

Roofing nails

Choosing the appropriate nails is a very important step in planning for a re-roofing. There are many different types of nails available, but nails for a roof are specifically designed for nailing shingles. Typically, roofing nails are made of stainless steel, but sometimes they are made of aluminum. They also have very large, broad heads compared to most other nails. Roofing nails are not measured by pennies but rather by inches and are clearly labeled as roofing nails.

Galvanized nails

Roofing nails tend to be galvanized, a process that makes stainless steel resistant to rust by coating it in a layer of zinc, which does not rust. Galvanization is very important when it comes to roofing nails, but even here you need to be careful because there are different types of galvanization. Try to find nails that are hot-dipped, which tends to provide the highest quality of zinc coating. Electro-plated nails, on the other hand, tend to lose their coatings more easily and it is best to avoid them if possible.

The nail shank

Nail length

Metal panels

You May Like: Where Do The Screws Go On A Metal Roof

Proper Nail Application For Asphalt Shingles

Reading Time: 3 minutes

Required by the International Building Code, proper nailing is essential to the optimum performance of roofing shingles. Accurate nailing requires the use of approved nails, nail-driving methods and placement .

Atlas has installation guidelines in place to ensure proper, uniform installation of Atlas shingles on every roof, whether that roof is new or recovered. Nails should have a minimum, nominal shank diameter of 11- or 12-gauge, and a minimum head diameter of three-eighths of an inch. The length of each nail must be a minimum of 1¼ inches long, and for roof-overs, Atlas recommends a nail length of at least 2 inches.

Nails of the proper length should penetrate three-fourths of an inch into the roof deck. However, where the roof deck is less than three-fourths of an inch thick, the nail should be long enough to penetrate fully and extend at least one-eighth of an inch through the roof deck.

Each shingle model has specific requirements for nails printed on each shingle wrapper. These guidelines must be followed to comply with building codes and ensure intended performance levels

All nails need to be driven either by hand or with a properly adjusted pneumatic nailer. Improper adjustment of a pneumatic nailer can result in overdriven or underdriven nails, which can cause nail corrosion, sealing failures, raised tabs, buckling and blow offs.

For more information about proper nail placement, visit atlasroofing.com/roof-shingles.

Do Command Strips Work On Vinyl Siding

To what surfaces will Command Products stick? Painted, stained or varnished wood, glass, tile, painted cinder block, plaster, metal, and painted wallboard. Command Outdoor Products can also be used on smooth, sealed and finished surfaces including vinyl siding and fences, doors, windows, decks, gutters and trim.

Recommended Reading: How To Extend A Metal Roof Overhang

Tips For Best Performance With Roofing Nails

Apart from using the right size of a roofing nail to install shingles, other things need to be kept in mind as well.

- Nails are galvanized to make them corrosion resistant. Good quality corrosion-resistant nails should be used because corroded nails can come off or cause development of rust in the shingles.

- Ensure proper placement of shingles and their alignment before drilling the nails.

- If there are cracks or holes in the roof deck, then the nails should not be installed on such surfaces.

- Do not use nails that dont comply with the size and type as specified in the roofing instructions if youve been given any. Also, make sure not to use more or less number of nails per shingle than specified.

- Under driven nails should be drilled down until they are at the right length inside the roof deck.

- Overdriven nails need to be removed altogether. If the nail has done damage to the shingle, it should be replaced along with the shingle.

Keeping these tips in mind before starting a roofing job can help eliminate a lot of hassle and problems that otherwise may occur and delay one1s work.

Can I Use 1 Inch Roofing Nails

In southern parts of the country where they dont need to deal with snow loads, its acceptable to use 3/8 roof sheathing, which means its also acceptable to use 1 roofing nails on asphalt shingles. A 1 nail will fully penetrate through 3/8 roof sheathing, but it wont fully penetrate 1/2 sheathing.

Also Check: How Much Shingle Roof Cost

Most Common Roofing Nail Materials

The metal a nail is made from can make all the difference not only in how well it holds down a shingle, but also how long it lasts over time. The most common types of roofing nails are made from aluminum, stainless steel, galvanized steel, and copper. We do not recommend all of these types, but that doesnt stop some contractors from using them.

How Many Nails Per Shingle Do You Need

A minimum of 4 nails per shingle is required for a standard asphalt roof shingle. A standard asphalt shingle is 36 long, and four nails spaced evenly along that shingle are adequate to secure the standard shingle size.

Shingles that are longer or shorter may require different amounts of nails. Manufacturers of those shingles will include specifications for how many fasteners are required for their shingles. Applying more nails per shingle is acceptable, within reason. However, 4 fasteners per shingle are industry standard.

Recommended Reading: How To Get Roofing Leads Without Door Knocking

When To Choose A Smooth Shank Nail

Another alternative available to use are smooth shank nails. These are seen as being a more cost effective option, although they still provide excellent value for money. Smooth shank nails tend to be made from either aluminium, stainless steel or copper. This is the most common type of roofing nail, and they are also used in a number of general construction applications.

What Are The Different Types Of Roofing Nails

Roofing nails are used in roof installation to fasten shingles, to install roofing felt for waterproofing and to attach roof tiles and sheet metal. There are different kinds of roofing nails, made of different materials and in various sizes. All roofing nails have wide, flat heads and short shanks. The tips of the nails are sharp and pointed for easy insertion so you don’t break the shingles or damage the wood when driving the nails through.

Different roofing materials require different types of roofing nails. Aluminum nails are good for metal roofs and shingles, but they are not recommended for areas where they can be exposed to chemicals or salt. If you live in a coastal area, use stainless steel roofing nails. Stainless steel nails are also good for fastening tiles and slate, or you can work with copper nails for standard roofing purposes. Galvanized roofing nails are steel nails that are zinc-coated. They hold up better against rust, and they can also be used for asphalt shingles.

Also Check: Cost Of New Roof Los Angeles

How Many Nails For Starter Strip Shingles

If you are installing starter strips and you should always use starter strips beneath your first course of roof shingles then youll need more nails. You should have at least 5 nails in your starter strip shingles, as they are your first defense against wind uplift and moisture penetration on your roof.

If you purchase a pack of starter strip shingles that covers 50 linear feet and your starter strip shingles are 40 long, then youll have 16 starter strip shingles per bundle. Multiply 16×5 and youll need at least 80 nails per one bundle of starter strip shingles.

How To Fix Nail Pops In A Roof

Nails can pop above the roof surface for a number of reasons. Perhaps they were underdriven in the first place. Nails that didnt fully penetrate the sheathing may work their way up over time. Or, if a roofs decking has warped or bent, it can pull nails out of place. Whatever the cause, its important to fix any nail pops in a roof to prevent damage.

Fixing the nails is simply a matter of removing them, removing the shingle and installing a new shingle. Be sure you to use the correct nail length and place it properly.

Do not simply hammer the nail down, renail it in the same spot, or use the same shingle. All of these methods could allow water through the roof. For example, if you remove the nail and drive it back into the same spot, your aim wont be perfectly accurate. There will be a tiny gap on one side of the nail or the other. Even if it is imperceptible to you, water will find it.

If you use the same shingle and add the nail back in a different spot, youre leaving behind a hole where the nail once was. Some suggest you fill this hole with roofing cement, but this repair option must be done carefully to maintain the roofs water-shedding performance.

Don’t Miss: Skylight On Metal Roof