What Type Of Osb Is Used For Roofing

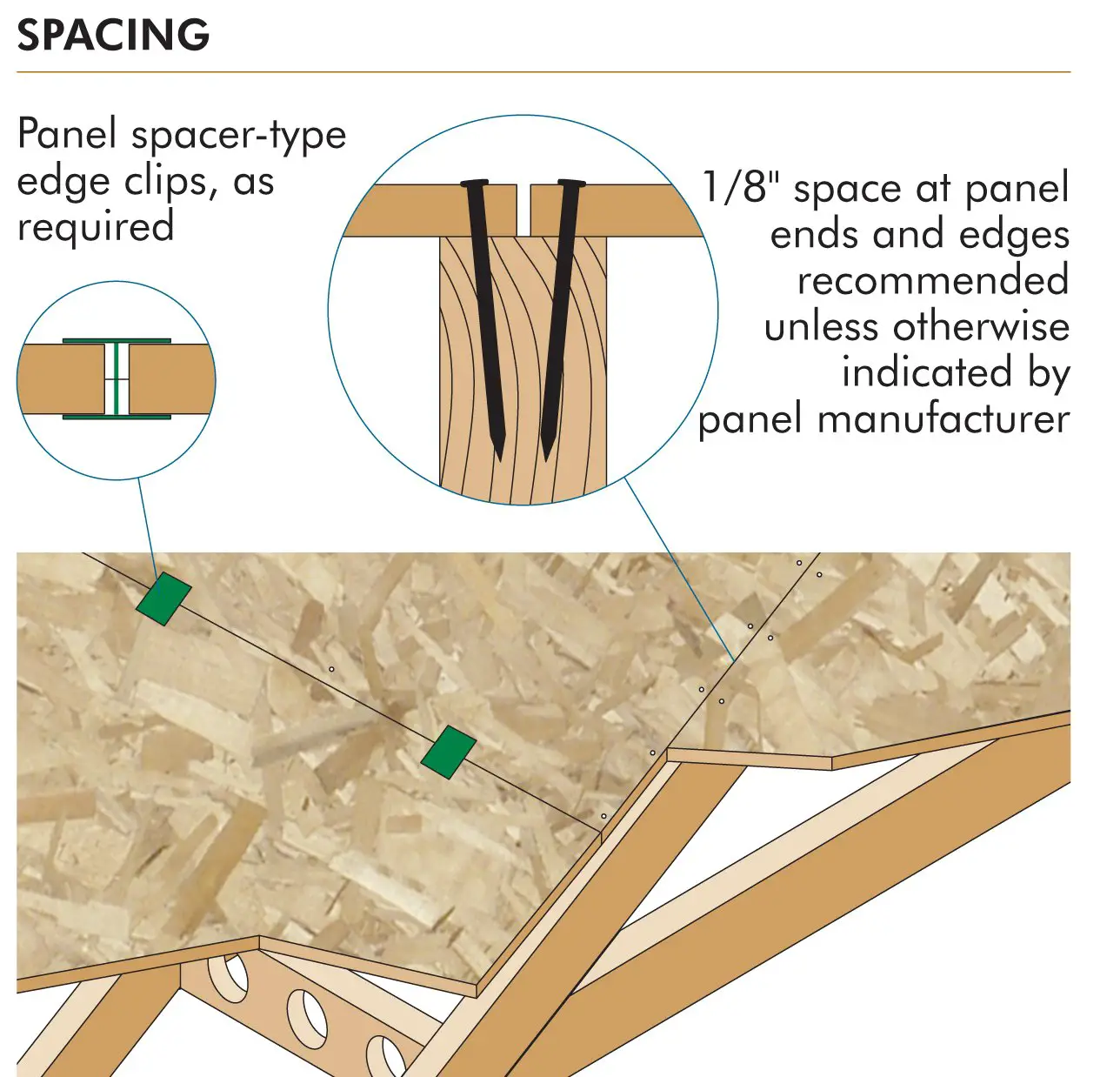

Half-inch OSB is suitable for rafter spacings up to 24 inches, whether or not the edges are supported. Sheets must have a 1/8-inch expansion gap between them and should be secured to the rafters with 8d nails. The nails should be spaced 6 inches around the edges of a sheet and 12 inches in the middle.

What Is Standard Osb Thickness

The thickness of sheathing panels is typically 5/16 inch . The length is 9 mm, and the width is 3/8 inch. The length of the 7/16 inch is 5 mm. The length of the metal is 1 mm, and the width is 15/32 inch. The length of the piece is 1/2 inch . The length is 7 mm, the width is 19/32 inch . The length of the ring is 1 mm, and the diameter is 15 mm. The diameter of the tube is 9 mm, and the length is 23/32 inch. There are two millimeters , and one inch . 0 mm).

Can I Use Screws For Roof Sheathing

Screws can be used for even greater withdrawal strength, but should be sized by the building designer. Staples are not recommended for roof sheathing attachment in high-wind areas. Oriented strand board is one of the most popular materials for roof sheathing.

Also Check: Shed Eave Overhang

Plywood Is Layers Of Wood

Plywood is made with three or more layers of thin wood glued together with the grain alternating. It is typically made in 4-by-8-foot sheets, although longer panels are available for special purposes. It is a flexible, durable, inexpensive covering for roofs because each panel will cover 32 square feet. It comes in multiple thicknesses from 1/4 inch to at least 1 inch those above 1/4-inch typically have five layers of wood. The material cuts easily using a circular saw or handheld cutting tool equipped with a 3-inch multipurpose carbide wheel which lends to its popularity.

What Else Can You Do With Osb

You could easily create all your furniture using OSB! The natural finish looks perfect married with white and has been used to create desks, tables, sofas and cupboards. Theres also a growing number of artists that use OSB as a canvas because of its great texture, it gives a unique finish with the layers of wood showing through. Here’s an example from the fantastic artist Coraline VB who has an Etsy shop at DessinsDeCoco.

Don’t Miss: How To Add A Gable Overhang

Osb Vs Plywood Screw Holding

Screwe holding ability is a critical matter in roofing. When the roofing material cannot hold nails and screws properly, of course, it cannot hold its shape very well. This is why you need to know the screw holding ability between plywood vs. OSB for roofing.

The full information will be displayed down below so that you will know which one is better.

Is Osb Better Than Plywood

Depending on your budget and structure, plywood can be a better option for roof sheathing than an oriented standard board . Both types of paneling are made from wood and held together using strong adhesives. However, plywood is a more heavy-duty option and can support more weight.

Despite being more durable, plywood is still a less-common choice for roof sheathing than OSB. This is because of the low price point of OSB.

While plywood might be more expensive, it requires less maintenance, is heavier-duty, more weather-resistant, and is more weight-bearing. The initial cost might be more but in the long run, roof sheathing that can withstand time and withstand weather is worth the money.

Don’t Miss: How Much For Shingle Roof

Not All Osb Are Created Equal

Although OSB is quite strong and reliable to be used in the roof sheathing, you should know that there are two types of OSB out there, which vary in durability, insulation, and price.

These two types are known as OSB2 and OSB3. OSB2 is the more affordable variant of OSB. However, its typically used for bearing light to medium weight loads and specifically designed for being used in mostly dry conditions.

On the other hand, OSB3 is typically used for load-bearing projects, such as roof and wall sheathing.

Moreover, OSB3 has much better insulation and waterproof rating, which allows it to be used in humid conditions. Yet, this type of board is more expensive and is used almost exclusively in structural projects.

What Kind Of Nails Do You Use For Sheathing

nails

Using proper nails to attach sheathing will help your roof withstand strong winds. Traditional sheathing material typically comprises 15/32-inch plywood or oriented-strand-board panels. Builders generally use 8d common nails, which are approximately 2 ½ inches long and 131/1000 inch wide in diameter.

One may also ask, should roofing nails go through the sheathing? A 1nail will fully penetrate through 3/8roof sheathing, but it wont fully penetrate 1/2sheathing. The other way to determine if the proper nails were used is to look in the attic if the roof has 1/2sheathing, you should be able to see the nails sticking through in to the attic.

Considering this, what kind of nails do you use for plywood?

Framing nails are used for plywood assembly both interior or exterior. They are referred to as sinker nails, common nails and box nails. Sinker nails have a waffled head, which makes driving them easier, and a coating over the shank to keep them solidly in place once driven.

Can I use screws for roof sheathing?

Screws can be used for even greater withdrawal strength, but should be sized by the building designer. Staples are not recommended for roof sheathing attachment in high-wind areas.

Also Check: Maximum Metal Roof Overhang Without Support

Roof Sheathing Code Requirements

The minimum requirement for roof sheathing is thick. There is no upper limit on how thick your roof substrate is. Thickness allowed depends on how far apart rafters or trusses are spaced and the rating of your roof decking. For instance, there are panels rated for 24 rafter spacing.

Another consideration is if your rafter or truss spacing allows you to place your sheathing usually 4×8 panels so that each edge of the panel is supported. If that is the case, youll find that your framing can support thinner panels than if an edge does not sit directly above a framing member.

Of course, nearly all frames are designed to fit roof sheathing edges, so when you install your panels youll be able to screw or nail your panel edges into the framing. However, if you are retrofitting an old house or shed, you may encounter unusual spacings which will indicate your roof decking may need to be thicker than the spacing and label indicate.

Finally, code requirements do not differentiate between types of roof decks. Why? Because the APA the Engineered Wood Association creates labels for every piece of lumber they certify, OSB or plywood. The label clearly states maximum spans and loads allowed for that piece of roof substrate.

This makes it simpler for the consumer to pick out the right piece of product under their finished roof without having to worry about telling the difference between types of wood products.

What Is Better For Roof Sheathing Osb Or Cdx

Every board has its benefit when it comes to roof sheathing. Of course, OSB is a far more popular choice, but the easiest way to decide which wood is best for roof sheathing is to check out the benefits for yourself!

OSB is also less expensive than CDX plywood. So, if money is a consideration in your building, you might want to consider OSB an alternative to CDX plywood. Of course, both plywood and OSB have benefits, but OSB is a better choice because of the weather resistance and durability.

Recommended Reading: Cost To Install Trusses

What Is Better For Roofing Osb Or Plywood

Plywood Holds the Moisture Advantage Over OSB When plywood gets wet, it tends to swell. OSB takes longer than plywood to get saturated, but also takes much longer to dry out. When used as roof sheathing, this tendency to hold moisture means it will degrade faster than plywood when exposed to chronic leaks.

How Do I Know If My Roof Sheathing Is Bad

Checking for damages on your roof sheathing will let you know if its in bad shape.Like any other roofing material, roof sheathing gets damaged and may need repairing or replacing.

Roof sheathings come in wood, concrete, and steel materials. The last one, the steel sheathing, is unlikely to sustain damage because it is high-quality and durable steel.

On the other hand, concrete is good and can last long without much maintenance or repairs, especially if the sand, the cement, and the waterproof material are mixed in the correct ratios.

When the cement is not enough, the concrete mixture becomes porous, and water will eventually seep through, and the sand making up the concrete will start to peel and fall.

In wooden roof sheathings, the damage is inflicted through moisture, high temperatures, and pests which are easily noticeable when you see:

Also Check: New Roof Cost California

What Is The Standard Roof Sheathing Thickness

Standard roof sheathing thickness is ½ to thick. If you are using OSB for your roof deck, then is the recommended thickness. For plywood, which is slightly stronger than strand board, ½ thick is appropriate.

Another factor is how far apart your trusses or rafters are spaced. 24 and 16 are the most common spacing, and youll often find 16 standard for rafters and 24 standard for trusses. A thicker panel may be required for 24 compared to 16, so if you have larger gaps between the framing, consider a thicker substrate.

It is important to note that there is no standard sheathing thickness, at least officially. When you purchase roof decking, it will have an APA stamp with two numbers beneath, divided by a slash. The first number tells you the maximum distance that the panel can bridge between gaps.

Therefore if you pick up some sheathing that is 12/0, that means the max gap it can bridge between rafters or trusses is 12. If you get panels that say 24/0, it can span up to 24 between framing members. Therefore, there are many options available.

How Thick Should Exterior Plywood Sheathing Be

The International Residential Code specifies 3/8-inch plywood for sheathing walls with a standard stud spacing of 16 inches, if the siding is nailed to the studs through the sheathing. If the nails penetrate the sheathing, but not the studs, the minimum plywood thickness that the IRC designates is 1/2 inch.

You May Like: How Much To Shingle A House

What Should I Use For Roof Sheathing

It is possible to use Oriented Strand Board or plywood, although plywood will have a higher pull-through resistance than OSB. You can use panels rated as Exposure 1 or better if you want to. The Engineered Wood Association recommends installing sheathing panels according to its recommendations. Panels should not be less than 4 feet long.

Overview Of Normal Minimum Thicknesses For Different Uses:

- 9 + 10mm: packaging, protective panelling, furniture

- 12mm: water-vapour-inhibiting, airtight and reinforcing inner boarding in walls

- 15mm: inner boarding of walls and roofs to comply with the fire protection requirements of DIN 4102-4

- 18mm: loadbearing ceiling panels

- 22mm: loadbearing, reinforcing ceiling and roof panels

- 25mm: ceiling und roof panelling with widely spaced rafters and trusses and greater loads

- 30mm: panelling for fire resistance of 30 minutes based on the burn rates defined in DIN EN 1995-1-2

- 40mm: special applications involving heavily loaded constructions or enhanced fire protection requirements

Also Check: Large Overhang Roof

The Value Of Integrity

The roof sheath provides integrity to the structure and the house at large. The strength and stability to withstand adversity will earn respect and be approved as safe to dwell in or work. A roof sheathing will add strength and provide a barrier to water and moisture from seeping through the roofing structure.

What Size Roofing Nails Do I Need

What size roofing nails to use?

Composition ShinglesComp ShinglesSheathing Thickness 3/8 1/2 5/8 3/43-Tab comp shingles 1 1 1 1Dimensional comp shingles 1 1-1/4 1-1/4 1-1/43-Tab comp shingles over 3 Tab comp shingles 1-1/4 1-1/4 1-1/4 1-1/2Dimensional comp shingles over 3 Tab 1-1/4 1-1/2 1-1/2 1-1/2

*More than 1 layer of roofing not recommended over 3/8 Sheathing

Wood ShakesWood ShakesNail TypeMinimum Length18 Straight Split 5d Box 1-3/418 and 24 Handsplit and Resawn 6d Box 224 Tapersplit 5d Box 1-3/418 and 24 Tapersawn 6d Box 2

Wood Shingles Wood Shingles Nail Type Minimum Length18 Straight Split 3d Box 1-1/418 and 24 Handsplit and Resawn 4d Box 1-1/2

DisclaimerThe above nail sizes are recommendations only. Consult your local building department for specific nailing applications.

Recommended Reading: Shed With Overhang Roof

What Is The Best Osb For Roofing

With 24-inch truss/joist spacing, the National Wood Flooring Association recommends 1-inch OSB underlayment, compared to 7/8-inch plywood. Depending on thickness, plywood is also approximately two pounds or more lighter per sheet. Perhaps, plywoods biggest feature is the homeowners perception of higher quality.

Plywood Is Better Than Osb For Subfloors:

Despite its common use as such, we don’t recommend using OSB for subfloors, but that’s really just for aesthetic reasons. New homes will usually see a few rainfalls before a roof is on, and as noted above, OSB doesn’t handle moisture well. In the case of a subfloor, deformations left in the OSB after it dries can lead to wavy flooring.

Some developers have had problems with that when delivering homes to the owners, and had to pull up and replace newly installed hardwood floors. The ability of plywood to return to shape after wetting makes it a lot less risky in this application, and while a little more expensive, that’s still cheaper than having to replace a floor.

Read Also: Trailer Roof Repair Cost

Roofing Plywood: Sizes Material Options Thickness Calculations Osb

While its not the main material for the roof itself, roofing plywood is an important part in a roofing structure. Its so important that you have to arm yourself with knowledge and know everything there is to know so youll know the best way to utilize it for your roof.

Read on to know more about this material. Youll know how its used for decking and sheating. Youll also know the different size and thickness requirements. Youll also learn how to calculate to find out how many sheets you need for your roof.

What Can It Be Used For

Theres a variety of DIY projects that OSB is fantastic for and you can use it for both interior and exterior use as its weather resistant . Its regularly used for flooring because of its strength and its ideal for a workshop or shed. It can also be used for roof sheathing to go under your roofing system or as a sheathing on the walls.

But for a creative person or carpenter OSB can be used to create a multitude of different pieces of furniture or cabinetry as well. With a little creativity the sky is the limit with the endless options, headboards, noticeboards, drawers and wardrobes.

If you are thinking of using it in the garden, although its weather resistant, for permanent outdoor use you will probably want to add some further weather protection. The weather resistant sealant will also only have been applied to the surface of the OSB so as soon as you make a cut into it you will want to add more sealant to ensure that water is not absorbed through the exposed material.

If you are going to add some more water protection, its worth adding some to an offcut of the OSB first to see the effect it has before carrying it out on your whole board. Once youve applied the sealant you can test the offcut by putting some water on it and leaving it for a few hours to see the effect.

Recommended Reading: How Often Does The Roof Need To Be Replaced

Size Of Roof Sheathing

Im getting ready to do a roof and Ive noticed a lot of the roofs in the area have dips between the rafters or trusses, which I would guess is from using too thin of a plywood or OSB sheathing. My addition will have trusses 24 O.C. with a 8:12 pitch on the main roof and a 5.45:12 pitch on a shed dormer, both with asphalt shingles. Im in the Mid-Atlantic region so snow load is a consideration, too. The lumberyard spec is for 7/16 OSB. From everyones experience, is that sufficient or should I up the size to 1/2 or even 9/16? Ill be using H clips between the trusses.

Thanks in advance for you input.

Most of us use 7/16″ OSB for wall sheathing. Every manufacturer of OSB, I’ve worked with, requires full support on all edges of the 7/16″ sheathing. We don’t consider OSB to be a suitable choice for roof sheathing. H clips do not meet the edge support requirements. The better builders will only use 5/8″ CDX plywood for roof sheathing, some use 1/2″.

Industry is always offering new products. Many builders use an OSB like product on floors, such as Advantech. This is a product that may look like ordinary OSB but is quite different. It’s too heavy to handle on a roof and too expensive. There may be some new OSB roof sheathing products that I haven’t used but ordinary wall sheathing would be a poor choice. The builders that use 7/16″ OSB for roof sheathing are the ones to avoid.

Beat it to fit / Paint it to match