Which Metal Roof Has Better Expansion Capabilities

The metal for your new roof will go through something called thermal expansion. Thermal expansion occurs when a material expands when heated and then contracts when it cools down. The expansion capability of the two systems determines which is better for your specific situation.

Standing seam panels are fastened under each rib. The fasteners under the ribs allow the roof to expand and contract freely as the clips stay fastened and the panels glide back and forth. Unlike screw down panels, this allows the panels to expand and contract freely.

A screw down metal roof system is installed by securing the panels down by screwing through the metal. The problem is, this method of screwing the metal down, doesnt allow the metal to expand and contract naturally. Due to the lack of being able to expand and contract, the screws will eventually wallow out the holes they are screwed into. This means that you will periodically have to replace the screws with the next size up.

Due to a lack of expansion capabilities on a screw down panel roof system, I do not recommend that you use this type of roof system over any heated living or workspace. Beware, there are many contractors that will install this type of roof system without telling you about how expensive it is to maintain.

Steel Roofing: Screw In The Flats Or The High Ribs

It was a pleasant October evening back in 1985 in Blacksburg, Virginia. My friend Dr. Frank Woeste was then a professor in the College of Agricultural and Life Sciences at Virginia Tech and he had invited me to teach one of his classes for a day, in exchange for him providing some basic engineering software which would design post frame building columns, roof purlins and wall girts.

Now back in 1985, Virginia Tech had not yet become the NCAA football powerhouse it grew into under the direction of Hokies head coach Frank Beamer having now participated in post season bowl games for each of the last 23 seasons. This also long predated the April 16, 2007 tragedy in which Virginia Tech student Seung-Hui Cho fatally shot 32 faculty members and students, wounding 17 others before killing himself on campus. This shooting remains the deadliest mass shooting committed by a lone gunman in United States history.

Mid-way through the evening with Frank, after digesting a hearty meal and debating whether the hops in the liquid consumed were a fruit or a vegetable , we digressed into the true essence of Dr. Woestes research at Virginia Tech which was post frame buildings and prefabricated metal connector plated wood trusses.

Narrowing things down, a lively discussion occurred on whether steel roofing and siding for post frame buildings should be attached with screws through the flats or on the tops of the high ribs.

And The Best Way To Prevent Screw Or Fastener Issues Choose A Roof With No Exposed Fasteners

As you can see, there are several concerns to keep in mind when it comes to installing corrugated metal properly. But there IS a way to avoid all of that potential stress to begin with. Just go with a custom-fabricated, professionally-installed standing seam metal roof! Here just a few features of standing seam that make it the best metal roofing option:

Also Check: How Much Is Tesla Roof

What Is The Most Common Cause Of Metal Roof Leaks

The single biggest cause of leaks on a metal roof is due to incorrect fastener installation. Once you learn about screw placement we recommend that you learn how to install the fasteners correctly. Your roof will have thousands of screw penetrations and watching this video is the best thing that you can do to prevent roof leaks.

If you prefer to read about installation of metal roofing fasteners we wrote you an article:

How To Remove Metal Shavings From The Roof

Swarf is the metal shavings and chips that are caused by cutting and drilling roof panels. These fragments tend to rust quickly if they are not removed from the roof in a timely manner. Leaving swarf on the panels after drilling will cause red corrosion spots to form and permanently stain the roof. This can and does happeneven overnight.

Read Also: When Is The Best Time To Replace Your Roof

Metal To Light Gauge Metal Screws

This type of screw can be used on a metal roofing or siding job. For a metal roof, the most common application is attaching to metal purlins. For a metal siding job, its an attachment to metal studs.

You will use this type of screw when the thickness of the metal purlins are 14 or 16 gauge. An example of this type of screw is a #12-14 Impax.

Do The Screws Go In The Ribs Or In The Flats

When it comes to corrugated metal paneling, one question that always comes up is exactly where to put the screws on the metal roofing in the first place. Many advise that screws should be put in the flats or valleys only, while others swear that the screws should go in the ribs. To get an idea of how hotly-contested this topic can get, take a minute to scroll through the comment section of this popular metal roofing comparison video shared by Skywalker Roofing owner Luke Wilson!

Why do people get so passionate about this subject? Well, the screws-in-the-rib proponents say that putting screws in the flats could subject your metal roof to more potential points of leakage, since water is naturally directed to the flat areas. Screws-in-the-flat fans counter by arguing that screws placed in the rib dont create proper gasket compression, due to the presence of a void under the rib. Another potential problem with screwing into the rib is that it presents a higher risk of the screw pulling out during a wind event.

Recommended Reading: How Do You Tarp A Roof

Screw Line Spacing For Metal Roofing Sitting On A Solid Wood Substrate

When you are trying to determine screw line spacing you have to realize that each job is different. Some jobs are located in areas that have high winds while others may be located in snow country or a desert. For this reason the spacing between screw lines should be determined by the engineer. However, this rarely happens.

In the real world the homeowner or installer chooses a distance without consulting an engineer. The overwhelming majority of the jobs we sell are installed with screw lines at 24 on center. Jobs that are not installed at 24 on center are usually at 18 O.C. if closer and up to 36 O.C if further. When in doubt more attachment is better than less attachment.

Formula For Determining How Many Screws Will Be Needed

Here are two easy formulas for determining the amount of metal roofing screws:

Example: 3,000 square feet X 80% = 2,400 screws

Example: 30 roofing squares X 80 screws = 2,400 screws

Do Not Forget To Order Metal To Metal Screws For The Trim And Panel Sidelap

Example: 3,000 square feet divided by three = 1,000 then divide that by 1.5 = 667 screws

You dont need metal to metal screws for the sidelap if using Corrugated. You will only need sidelap screws for R Panel/PBR Panel and Western Rib/7.2 Panel.

Recommended Reading: Is It Cheaper To Do A Metal Roof Or Shingles

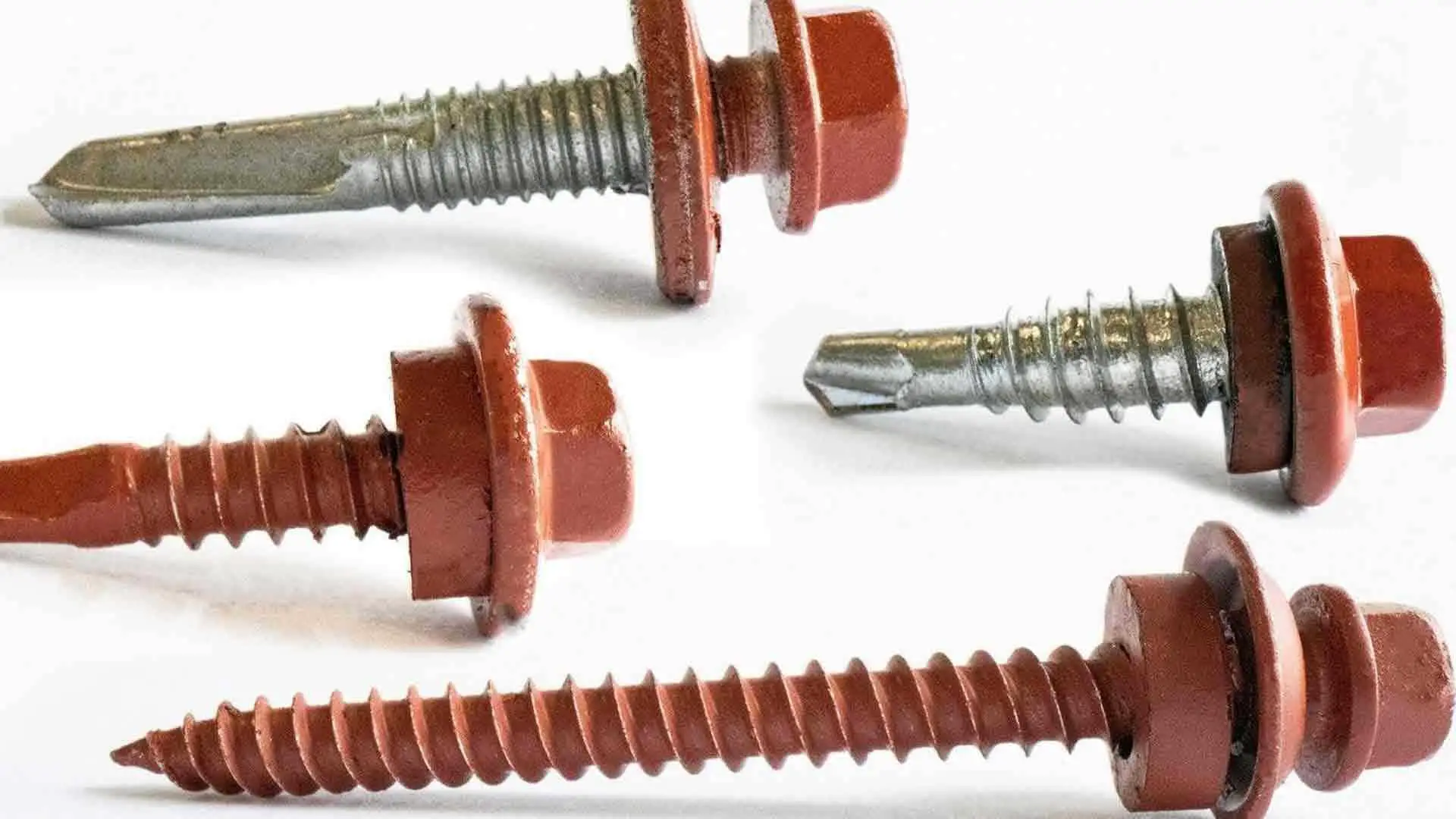

What Are Metal Roofing Screws

When installing a metal roof you need to use metal roofing screws, complete with metal washers. Metal roofing screws are used to attach metal panels to a structure or building, for instance, wood substrates or steel, these screws come in various sizes, materials, and designs.

To keep your metal roof strong, youll need the correct equipment, including the right screws. Its best to use strong metal screws instead of nails, this is because nails can easily become loose, or bend due to heat exposure.

Your roof screws or fasteners help to stop your metal roof from leaking. The problem is, exposed roofing screws can wear out, . When youre replacing your metal roofing screws, you should consider these things:

- Use fasteners with a V-neck shaped strong head, .

- Match the color of your roof panel and your roofing screw .

- Using galvanized screws offers added protection from corrosion.

How Far Apart Do You Put Screws On A Metal Roof

youroofing screwsclose tofar apartroofing screwapart

. Just so, how often do you put screws in a metal roof?

How to Replace Metal Screws. Corrugated roof panels and other exposed fastener metal roofs are usually held together with screws every 18 inches or 2 feet. You will want to note your metal roof screw pattern, so you know where to look for potential problems.

One may also ask, how do I calculate how many roof screws I need? To calculate sheet length and quantity, click here.M) of your roof by multiplying LM by the coverage area. The coverage area for corrugated iron is 0.762m as denoted by the 762 in the product name. Finally, multiply the Sqr. M by 7 to find the number of screws needed.

Beside above, how do you install exposed fastener metal roofing?

Exposed Fastener Installation

Do you pre drill metal roofing?

More on how to install metal roofing:On exposed fastener panels: While you are not required to, consider preâdrilling holes for your screws. Preâdrilling panels will make it easier to get the screw lines straighter. Otherwise, they will cause unsightly rust spots where they rest on the metal roofing.

Don’t Miss: How To Get Out Of Roofing Contract

Importance Of Using A Roofing Screw

Screws invoke immense pleasure and are appreciated for his or her superior fastening mechanisms. There exists a good range of roofing screws available during a sort of materials, sizes, and designs.

One such type is that the roofing screw. Roofing screws are typically manufactured from chrome steel or aluminum and are threaded up the whole length of the shaft.

Furthermore, roofing screws are often manufactured with washers to supply extra support, which is vital considering the extent of exposure roofing screws must withstand consistently.

Appropriate Screws Installation Is A Key To Successful Metal Roofing:

Well, people are considering the installation of metal roofs because of several reasons. The main reason is that this type of roofing requires low maintenance. Moreover, the durability and life span of this material are more than others. If you think about adding the solar panels or system, it would be a great option to add it on the metal roof to reflect more light with better Sun exposure.

If you want to keep the metal roofing long-lasting and durable, you have to install it appropriately. Without the proper anchoring of screws, its impossible to place the metal strips and sheets properly.

However, the installation and addition of screws depend on the type of metal sheets. There are different kinds of screws such as metal, wood and lap screws used to tight the metal sheets on the roof.

If you dont handle the screws and put them according to the type of metal, the chances for moisture intrusion and damages are high. Unfortunately, the replacement of the metal roofing will surely cost you more than professional installing of screws. Now, the decision is yours.

Read Also: How To Remove Lichen From Roof

Whats The Correct Screw Length For Metal Roofing

If your fasteners arent long enough to penetrate through all of your material, its safe to say youre not going to have a successful installation. The right fasteners must not only be long enough to go through the material, but you must also take into account the length of the drill bit if you are using self-drilling screws.

Most importantly, you want at least one inch of screw penetration into the material that you are fastening to.

The length is usually rounded up to the next half or quarter inch to ensure the fasteners are long enough. Keep in mind that the longer the screw, the more torsional strain is produced during driving. Sometimes this can cause the fasteners to break during installation.

Choosing The Right Diameter For Your Metal Roofing Screws

The diameter of the screw is measured by the diameter of the shank. The higher the number, the wider the screw.

Choosing the correct screw will vary based upon the local building codes, climate, contractor preferences, and the engineering specifications of your job. Every job will be different and every screw has different pull-out values. The best we can do is to give you some general guidelines.

Here are the most common screw diameter sizes:

- #9 & # 10 – These are the most common sizes for metal to wood screws

- #12 – This is the most common metal to metal screw

- #14 – Wider screw thats used in areas with heavier snow loads

Also Check: How To Replace A Flat Garage Roof

Metal Roof Screw Pattern

Installing a metal roof incorrectly is crucial, including how it is screwed to your house. Take an example of a standing seam roof with flat and broad panels that interlock by protrusion to give the roofing system a lot of strength.

Read also: Things that You Must Know About Metal Roofs

Being made from copper, aluminum, zinc, or galvanized steel, the standing seam roof panels are fastened using screws and concealed to make them last far longer and prevent them from being failed.

There are different metals or metal combinations of screws that can give a different result. The standard ones are made mostly from carbon steel and coated by corrosion resistance material.

Meanwhile, the metal roof screw pattern will depend on the number of fasteners used that also depends on the purlin spacing and panel profile. Below are two easy and common formulas you can use to calculate screws for metal roofing.

For example: 2,000 sq. ft. x 80% = 1,600 screws

For example: 20 roofing sq. x 80 screws = 1,600 screws

Installing On The Low

Installing the screw on the low will not leave any space between the screw, the metal panel, and the roof. This will, in turn, be a much stronger joint. Its unlikely that you will damage the metal roof panel by over-pressing the screw.

On the other hand, the Low of the corrugated sheet is like a small valley. And if you have ever been to a valley, you will know that they are great places to collect water. The washer of the screw is normally bigger than the screw head, which means that it will hold a larger surface area of water behind it, causing damage to the screw and its screw head.

Recommended Reading: When Does A Roof Need To Be Replaced

How Long Will Your New Metal Roof Actually Last

Now you know how the two types of metal roofs compare to each other on key factors. This helps you decide which one is right for your situation.

But there’s still one more factor we didn’t discuss, a metal roof’s lifespan. Because lifespan is the return you get out of your metal roof investment, we wrote another article breaking it down for you.

Since 1990, the team at Bill Ragan Roofing has been installing residential metal roof systems for homeowners in the Nashville are.Whether its installing your new roof, regular maintenance, or roof repairs you can count on us to do the job right.

Check out this article on How Long Your Metal Roof Should Last to learn how much life you get out of your metal roof investment.

Bend Trim Ends Closed

- Before you install the trim, cut and bend the leading end to wrap it around the corner. Make a series of one-inch cuts with aviation snips at each bend to create tabs. Fold the tabs in with a hand seamer to meet a wall or a corner, or to close a gap created by the trim. Each trim is a different shape, requiring unique cuts and bends.

Also Check: How Much Do Louvered Roofs Cost

Roofing Screws Metal To Wood

The most common type of metal roofing fasteners are metal to wood roofing screws. Fastener manufacturers usually specify pull-out strengths for a variety of different types of wood as not all wood is the same. This helps to determine the right fastener for your project.

An example of a fastener for a wood substrate is the #9 metal to wood screw or the #10 metal to wood roofing screw. These screws have an extra sharp self-piercing point that can penetrate 20-29 gauge steel sheeting and then into the wood without pre-drilling, slipping, or damaging the metal panels.

Aluminum Shingles & Standing Seams: Metal Roofing Options

There are a variety of options and metal roofing prices, and if you are considering installing a new metal roof, the variety might seem overwhelming, and there are a lot of reasons to consider getting a metal roof versus shingles, or vice versa.

Knowing the difference between shingles and standing seams is perhaps the first thing that you should learn, and theres more to it than the cost.

After that, you can get into the various types of metal, their appearance, and the available paint finishes, then all of a sudden that are lots of decisions to make.

Read Also: How To Roof A Low Pitch Roof