What Is The Best Recommended Standing Seam Metal Roof

There is no one-size-fits-all when it comes to standing seam metal roofs. The type of roof you will choose will depend on several factors, as we have outlined above.

Mechanically seamed profiles will work best with very low-sloped roofs. Therefore, it is the best option for buildings in areas that experience extreme weather conditions. A nail strip profile is the most budget-friendly option. It is the easiest roof style to install and is, therefore, the best for DIY projects.

If you are looking for the best balance in performance and price, a snap-lock profile is your best bet. It is easy to install and will work for roofs with a 2:12 pitch or more. Snap-lock is the best all-round standing seam profile.

Types Of Metal Roofing + Pros And Cons Of Each

There are a number of different materials used for metal roofing, and three basic ways that its installed. These three different ways are referred to as the types of metal roofing.

- Hidden fastener metal roofing

- Exposed fastener metal roofing

- Stamped metal roofing

Each of these types comes with its own benefits and disadvantages. But despite those different benefits, homeowners most often choose their roofing type based on the look that they want.

Questions You Can Ask Yourself:

Do you want a lifetime roof?

If youre planning on moving within the next 5 years, then replacing your asphalt roof with a metal material might not be for you. Metal roofs receive the best return on investment when you live in your home for a long time. If youre going to move out of your house before a regular asphalt roof would need to be replaced, then investing in a metal roof doesnt make as much sense. With that being said, a metal roof could improve the value of your home depending on the market.

What is your budget?

Determining your budget will allow you to assess what type of roof youre able to purchase. As weve discussed, metal roofing is more expensive. If the price of a metal roof isnt in your budget, then the investment wouldnt be worth the high upfront costs.

Do you like the aesthetic of a metal roof?

Read Also: Trailer Roof Repair Cost

How To Measure A Roof For Metal Roofing

If your roof has cracks, holes or leaks and you need to change it, metal roofing is the best option. Before ordering the metal panels, you need to know how to measure a roof for metal roofing so that you can calculate the total number of panels you need for your roof.

Measuring a roof is not a difficult task. But the method of measuring may differ from one roof to another. Some roofs have uneven edges like valleys and dormers, and therefore you need to consider the area of these uneven edges while calculating the total square footage of your roof. Read on to learn how to measure a basic roof with even edges in just 4 simple steps.

Most Popular Types Of Metal Roofing Compared

Metal roofing offers an affordable way to have a forever roof. Thats right, you dont need to modify your home, and in most cases, you wont even need to modify the existing roof trusses. Many homeowners have decided to switch to metal roofing because of the beautiful and unique options that are available, separating their homes from the asphalt roofs that all of their neighbors have.

Beautiful, long-lasting, and a good return on investment? Lets break it all down along with the best types of metal roofs so that you can decide if metal roofing is right for you!

Don’t Miss: Attic Trusses Cost

What’s The Best Gauge For Metal Roofing

Our goal in this article is to explain when a heavier or lighter gauge makes sense. Choosing the correct gauge of metal roofing can be very confusing. The higher the number of the gauge, the thinner the thickness of the metal roofing. For example, 29 gauge is thinner than 26 gauge and 24 gauge is heavier than 26 gauge. Then it gets even more complicated because different metals have different measuring standards. The thickness of copper is different than for steel.

The most common gauges for metal roofing are 29, 26, 24, and 22 gauge. The vast majority of what we sell is either 26 gauge metal roofing or 24 gauge metal roofing. Low end agricultural jobs are normally 26 gauge or 29 gauge. While a beautiful new home with a standing seam roof would likely be 24 gauge. If that same home is done with an exposed fastener panel it would likely be 29, 26, or 24 gauge.

How Do You Measure Sheet Metal Thickness

You can find the thickness of your sheet metal by using a measuring tape and a simple conversion technique. First, use the tape measure to find its thickness in millimeters. This helps get the most accurate measurement. Second, multiply the number of millimeters by 0.03937. If your original measurement was 40 millimeters, the new one would be 1.5748 in inches.

You May Like: What Size Nails For 7 16 Osb Wall Sheathing

Measuring Your Roof Account For Roof Penetrations

Oh, and dont forget to list pipe sizes for boots, and dimensions for any skylights, chimneys or other roof penetrations on your sketch.From there, our Measuring and Estimating Guide will show you how to calculate the list of materials needed. If youre not comfortable with completing that yourself, no problem. Just give us a call at any of our locations and we will be happy to help you out.

Jump to:

What Metal Roofing Thickness Is Best For Panels That Will Be Spanning From Purlin To Purlin

This conversation starts with the gauge you should NOT use. Metal roofing in 29 gauge is just too flimsy to be used in this application. The appropriate gauge ranges from as light as 26 gauge to as heavy as 20 gauge. The further the metal roofing has to span between each support than the heavier the gauge needs to be.

When you have a short span of four feet or less, a lighter gauge such as 26 gauge may be appropriate. If the span is between four and six feet, a 24 gauge is appropriate. For spans longer than six feet, a heavier gauge steel is likely required. Every job is different and there are different requirements for uplift and load capabilities. Therefore, always consult an engineer to come up with the panel type, panel gauge, and the appropriate distance between metal purlins.

When you are comparing different bids from metal roofing contractors it is important to pay close attention to the gauge of steel that will be supplied. A metal roof that is manufactured from a heavier gauge steel will be stronger, handle foot traffic better, have additional wind resistance, and will be a longer lasting product.

Don’t Miss: How Much Does A Roof Cost In California

Reasons To Select Corrugated Iron For Your Roofing System

Corrugated iron is considered as the most popular and cost effective roofing material that you can select for your residence as it will last for a large amount of time. You will not have to replace the roof frequently as it is known for its durability and enhanced longevity. Therefore for ordering the best roofing material with fast delivery at lowest prices, you will need to visit .

Corrugated iron is the best option for your residential property as it will protect you and your family from the wrath of nature so that you can live safely inside your residence. It is the best roofing material that will make your home look visually appealing as you will also enjoy a host of benefits offered by trusted Australian- Bluescope, steel roofing. Moreover you will save a considerable amount of money with the easy as well as secure online ordering so that you will get the benefits for your property.

What Is A Metal Roof Panel

Panels are a fantastic metal roofing alternative for people searching for a long-lasting and budget-friendly material. A metal roof panel is a sheet of metal that covers your homes top.

It can be made from any number of materials, including steel and aluminum. In some cases the panels are painted to give them color or protection from rusting or corrosion, but in other situations they have no coating at all! Metal roofs come with many advantages over traditional roofing materials.

For example, they are extremely durable and can last for many decades with little to no maintenance! However, metal roof panels do come in different sizes.

Read Also: How To Extend A Metal Roof Overhang

Metal Roof Installation Prices

Professional metal roof installers charge about $350-400 per square for labor. Standing seam installation can start out as high as $500 per square, because its more difficult and time consuming to install this roofing system.

Typically, roofers charge 2/3 of the total roof installation cost for labor and overhead. Cost of roofing materials is 1/3 of the total price. When estimating the total materials cost, roofers will include a waste factor of about 5-20% depending on the architectural design of your roof and the metal roof style you choose. For example, on a complex roof, there will be more waste if you want to install standing seam panels, than if you install metal shingles or tiles.

Keep in mind that price quotes that you get online are for a basic install on a one storie ranch of cape style home. If your roof has a lot of penetrations , valleys, curves, your installation cost can significantly go up.

Roof pitch is another factor that can increase your labor costs. Installing a metal roof over a low pitch is much easier and quicker compared to a high pitch roof architecture. If your roof is curved, expect to pay at least 50% more for labor compared to a standard roof install.

Some roofing contractors can initially quote you a very low installation price, around $260-280 per square. However, they will then charge you extra money for every item of labor that they perform, such as:

ridge hip ventilation

Coverage And Side Lap For 1/2 Corrugated Metal Roofing

You lose coverage every time that you do this. This means that you will have to buy more square footage than the size of your roof or wall.

What You Need To Know About Buying ½ Corrugated Metal Roofing

In a roofing application you have to purchase 23% additional corrugated metal roofing and in a wall application it will be about 10% additional material.

When you purchase corrugated roofing the pricing is by the square foot which is calculated by multiplying the width of the sheet by the length of the panel.

For example, if you purchased a 26 wide panel that is ten feet in length it would be 21.67 square feet. You will pay for 21.67 square feet of material, but the roof coverage will only be about 17.77 square feet. Essentially, you need to purchase twenty three percent more roofing panels.

Also Check: How Much Does A Roof Cost In California

Measuring For Metal Roofing Measurements You Will Need

Then, to successfully complete your sketch, do your best and get the following measurements covered:Start with the panel lengths measure the panel length from the eave to ridge for each different eave-to-ridge distance.Then, get your width measurements the width measurements parallel to the ridge or eave will help you determine the number of 3 panelsYoull also need to cover the slope. So be sure to note the roof pitch in each section and indicate the down slope direction with an arrow on your drawing.

Types Of Corrugated Metal Roofing

Corrugated metal is a generic term that means any type of sheet steel strengthened for use in construction by having a series of alternating grooves and ridges forced into it. Technically, this could mean any metal roofing or wall panel. However, people that are in the industry define a corrugated metal panel as a metal roofing or siding panel that has S type wavy and round corrugations.

There are three basic types of corrugated panels: Corrugated, ½ Corrugated, and everything else including ribbed metal roofing panels.

Recommended Reading: Can You Put Skylights In A Metal Roof

Aluminum Shingle And Shake:

An aluminum roof designed for residential use will have concealed fasteners, interlocking panels and PVDF coatings. Accessories and trims will be factory-formed for quality and consistency. When reflective pigments are used in the paint formula, it is the most energy efficient option and classified as a cool roof. A cool roof quickly releases heat in summer and deflects the suns rays. The energy savings on a cool aluminum roof will help offset the premium you will be paying up front for the better product. With the highest strength to weight ratio of a roofing product, aluminum can be installed over the existing roof. Roofing over asphalt eliminates costs associated with tear down and disposal as well as decreasing landfill burden. Ideal for coastal or marine environments. If you live on the East or West Coast, look for products that are covered by warranty at any proximity to the ocean.

Maintenance required: NoneRe-Roofing Cycles Over 50 Year Period: None Expect to Pay: $14.00 $22.00 CAD per square foot installed.

Example of a standing seam metal roof with concealed fasteners.

Metal Roofing Prices Per Sheet

Metal roof panels are a very popular roofing choice, especially if you are looking for a budget friendly material. Economical corrugated metal sheet panels cost $3 6.5 per square foot installed, or $300-650 per square of roofing.

Metal sheet panels are available in a number of different styles, including: R-panel, 5V-crimp, corrugated and through-fastened panels.

They are made of either galvanized or galvalume steel and vary in thickness from 24-30 gauge steel. These panels can be painted or left as bare metal.

Cheap metal panels are good option for a barn, a storage space or a cabin style home.

Home Depot has a very large selection of various types of metal panels, sold in sheets. Steel metal sheets are available in various lengths from 5, 8, 10, 12, 16 ft. Sheet prices range from $18 to 52 per metal sheet. The most popular are 12 ft Classic Rib Steel panels that cost $39.84 each.

Also Check: How To Extend A Metal Roof Overhang

How Different Factors Affect Price:

Substrate: The pricing on metals used to form the roofing panel are affected by supply and demand for raw materials and associated processing costs. Galvanized Steel and Aluminum are the most common metals used for residential roofing because they provide the best performance for the money. Although exotic metals like copper, zinc and stainless steel perform exceptionally well, they are less common roofing options because the cost is prohibitive for most people.

Panel Design: The 2 major design options that affect price are overlapping vs interlocking panels. Interlocking panels will cost more than overlapping panels because they have more structural detail, go through a more extensive forming process and take up more room on a truck to ship. Panels designed to interlock on four sides will also tend to have a better quality finish which also adds to the cost.

Finish: Also referred to as coating, is an important factor to consider as it can drastically change the cosmetic lifespan of a metal roof. Polyester based paints are the cheapest form of coating with the shortest lifespan while PVDF formula coatings are accepted as the industry gold standard due to their exceptional lifespan, adhesion, chalk and fade resistance.

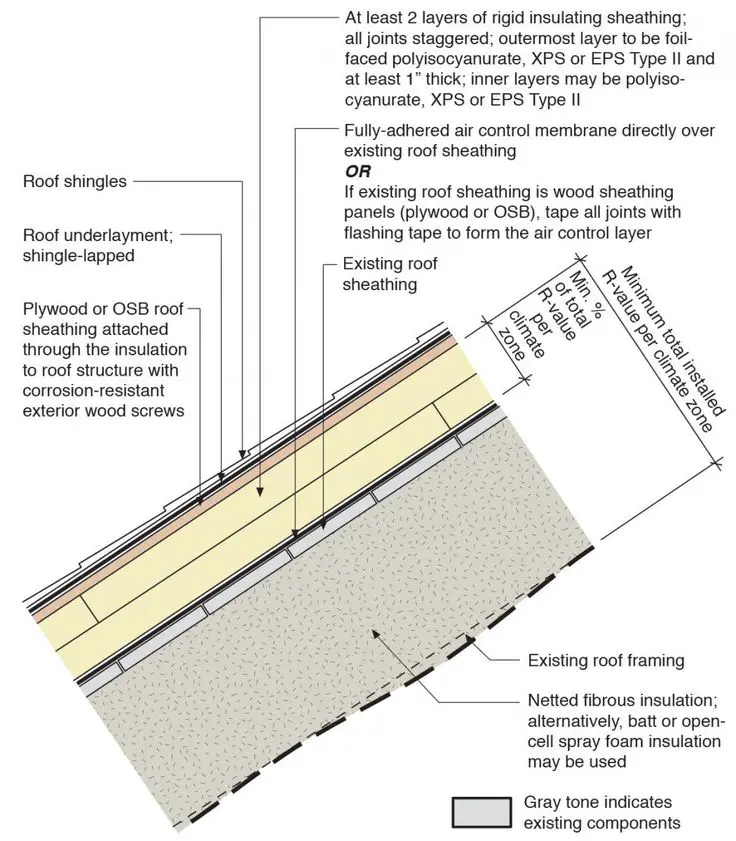

Underlayment: Often overlooked, the underlayment of a metal roof is a crucial second line of defense against the elements. If the roof is a new build it will require an ice and water shield which costs up to 5 times more than a breathable synthetic membrane .

Allows For Thermal Movement

When you restrict the expansion and contraction needed for proper thermal movement of a metal panel, you can run into problems, such as oil canning, fastener withdrawal, increased noise, and other issues. In standing seam metal roofing systems, the panels generally arent pinned, meaning they can expand and contract better. This is especially true if slider/expansion clips are installed, or, if its a snap-lock system, it can move freely with a clip.

You May Like: How Much Does A Roof Cost In California

What Is The Importance Of A Roofings Thickness

The thickness of the metal roof is important for several reasons. The thicker your panel, the stronger and more durable it will be against natural elements like wind, hail and fire damage.

Thicker panels can also carry a higher weight load- which means theyre better at containing heavy snow accumulation over time in colder climates.

Thin gauge panels are easier to install, but theyre also lighter and therefore not as strong. If you live in a climate with heavy winds or hail, then thicker panels are the better choice for your metal roofing installation project.

It is important for a homeowner to know about the gauge of their metal roof. When talking about metal roofing gauge, or thickness, is used. Thicker metal can counterbalance heavier snowfall and high winds.

Thicker steel roofs are the best when it comes to weathering harsh climates with heavy snowfall or high winds in places like Michigan, Minnesota, or in coastal regions.

Thinner metal roofing doesnt hold up in extreme weather conditions as well as thicker metal roofing. Thinner steel roofs are better suited for places where weather conditions dont tend to be so harsh.

The thickness of the metal used in a roof affects how long it will last, as well as its durability and its ability to withstand certain types of weather.

Thickness Of The Metal Panels

We refer to the thickness of the roofing panel as gauges. You will find different gauges of metal panels on the market, such as 24, 26 and 29. The 29-gauge sheets are thinner metal panels in comparison to 26 and 24-gauge sheets. The higher the gauge, the thinner the metal.

Another important thing to consider is that if you live in an area that is prone to hailstorms and snow, you should not opt for thinner gauges like the 29-gauge sheets. If you live in an area that does not receive heavy precipitation, 29-gauge metal sheets are durable, energy-efficient and inexpensive. The thicker the metal the longer it lasts. Check out more about how long does a metal roof last.

Don’t Miss: How Much To Shingle A House