Cons Of Galvalume Roofing

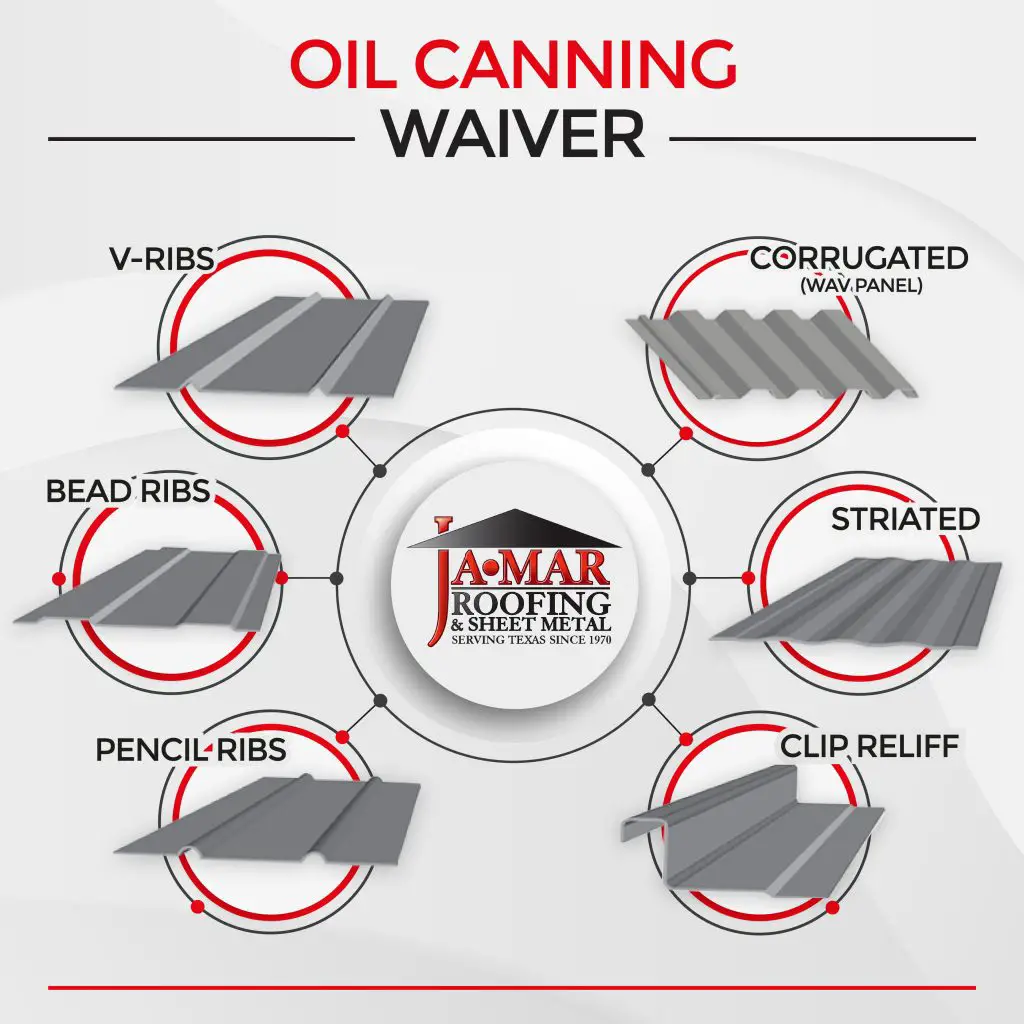

Oil canning Oil canning is an inherent characteristic of light-gauge, cold-formed metal products, especially products with broad flat areas. It is a visual phenomenon seen as waviness or distortion in the flat surfaces of metal wall and roofing products. Oil canning is subjective and normally only an aesthetic concern that does not affect a products strength or performance. This occurrence is possible for any kind of metal roofing or walls, including Galvalume. But there are methods to minimize the appearance of oil canning, including:

- Hiring an experienced contractor who knows the best methods to reduce oil canning, including:

- Panel thickness

Not suitable for animal enclosures or buildings Galvalume is not suitable for use on buildings where animals are housed or held. Manure from the animals breaks down into ammonia gas over time and then reacts with the Galvalume coating. This process breaks down the Galvalume coating and leads to the degradation of the metal. However, Galvalume is sometimes used on modern chicken houses built with a vapor barrier between the chicken area and the roof for appropriate ventilation. Its best to check with the manufacturer before putting Galvalume on an animal confinement building, as its often dependent on the specific design and use.

Choose The Right Panel Design

As you can see in the above images, different panel profiles are more prone to oil canning. Waviness or stress wrinkling is more obvious on flat and ribbed panels, while striated panels hide it much more effectively. With a striated panel, you also get the added bonuses of architectural appeal and extra strength.

How To Avoid Oil Canning On Metal Roofing

Building a home or commercial building is a huge financial undertaking. Naturally, youll want to be sure to make the most of your investment by extensively researching and planning, hiring skilled craftsmen, selecting high quality materials, and considering the big picture. One way to ensure your buildings roof will last for decades to come is to opt for a standing seam metal roof instead of a traditional asphalt shingle roof. While metal roofs are more durable than classic roof systems, they can still experience a phenomenon that impacts the appearance of the roof oil canning. Luckily, there are steps you can take to prevent oil canning, starting from the very beginning of the building process. Learn more about oil canning, and how it can impact your seam metal roofing system.

What is oil canning?

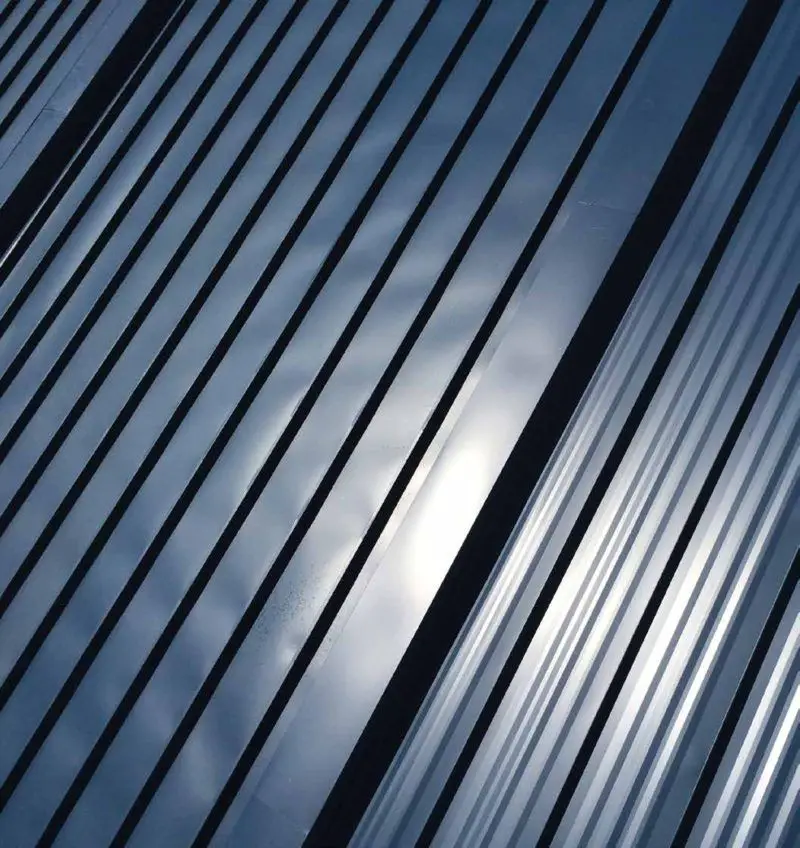

Oil canning, otherwise known as stress wrinkling, is a cosmetic roof issue that can cause the panels to appear wavy or distorted. It presents itself as waviness, bulkiness, and an overall unsightly appearance on metal panels between standing seams. The severity of oil canning can differ based on temperature and lighting condition. While oil canning doesnt impact the actual structural integrity of the roof or building, it can diminish the appearance of your new roof.

What causes oil canning?

Other causes of oil canning

Can oil canning be fixed?

How can it be prevented?

What should roofers consider while planning and installing the metal roof?

Don’t Miss: How To Mount Solar Panels On Roof

Standing Seam Metal Roofs Requires Less Maintenance Than Screw Down Metal Roofs

Every roof needs some kind of roof maintenance to ensure its running smoothly and reaches its full potential.

While both metal roof systems need maintenance, virtually none is required on a standing seam metal roof after its installed. You still need a roofing contractor to occasionally check the flashing around penetrations such as vent pipes, gas pipes, etc.

But other than that, cleaning is the only other general maintenance needed, and thats a personal choice for each homeowner.

Remember, the metal panels on a screw down metal roof cannot expand and contract freely. As time passes, pressure from the lack of expansion and contraction causes the holes in the washers to get wallowed out by the screws.

This leads to leaks and the need for regular maintenance. A contractor will have to come out every 5-10 years or so to replace every one of the screws before it causes bigger problems or before a strong storm tears the roof off.

Other Stresses To The Panel

Some other oil canning causes include:

- Not installing to the correct dimensions of the wall or metal roofing system

- Out of tolerance roof deck, such as concave, convex, or uneven planes

- Clips are too tight against the male leg of the panel

- Clips are too loose against the male leg

There are many different factors that can allow for oil canning to occur. The most important thing to keep in mind is that causing any unnecessary stress, movement, or tension on the metal panels opens the door for oil canning to develop.

Recommended Reading: How Big Of Hail To Damage Roof

Metal Roofs And Lighting

The misconception that metal roofs attract lightning is probably because metal itself is known as a good conductor of electricity, and people, therefore, assume that a metal roof must attract lightning. In reality, when lightning strikes, it is seeking a path to ground and almost always will strike whatever object is highest in the area that also has a direct path to ground. Your metal roof is not grounded, and thus lighting has no reason to strike it.

A metal roof in no way makes your home more vulnerable or susceptible to lightning strikes.

Dont Miss: How To Reseal Your Rv Roof

Top Considerations For Choosing Your Metal Roof

There are many different metal roofing options to choose from, but not all of them are well suited for your home or business. The best type of metal roofing will depend on your personal needs and preferences. Thats why its important to think about the following criteria before making a final decision:

Dont Miss: How To Install Solar Panels On Your Roof

Recommended Reading: How Many Squares In A Bundle Of Roofing

How To Prevent Roof Oil Canning

Standing seam metal is gaining popularity with homeowners as a durable, roofing alternative. One issue that occurs with metal roofs is oil canning or stress wrinkling that wavy appearance you see in the roof panel on the left side of the above photo. Oil canning happens to some degree with every type of metal roof, and while it doesnt affect the materials performance, it can detract from the good looks of your newly-installed roof.

If you want to minimize the visual effect of stress wrinkling, there are some preventive measures you should take while your roof replacement is still in the planning stages:

Some Actual Disadvantages To Metal Roofs

Fear of lightning strikes may be an imaginary problem, but there are a few genuine disadvantages to metal roofs.

The one disadvantage that poses an actual safety risk is the fact that metal roofs are indeed slippery when wet or when covered with snow. It is never a good idea to climb on a metal roof when it is moist or covered with snow. They are so slippery that snow avalanching off the roof is a definite hazard in areas that experience heavy snowfalls in winter.

There are some advantages to this, since snow that slips off the roof cant build up on top of it. People owning asphalt-shingled homes in heavy snow areas may need to rake snow off their roofs in winter, but this is never an issue on a home with metal roofs. But it is also possible for snow to avalanche off a metal roof in such quantities that it can damage decks, shrubs, cars, or even people.

In ski areas notorious for heavy snowfalls, metal roofs are often equipped with snow guardsmetal or plastic clips or even horizontal bars mounted to sturdy brackets. Homeowners can employ the same technology to prevent avalanches from the roofs of their homes.

Also Check: Do Metal Roofs Attract Heat

What Is Oil Canning On A Metal Roof

May 26th, 2021 | 5 min. read

If youre interested in a metal roof for your upcoming replacement, you should be doing a lot of research to determine if its the right roof for you. While doing your research, youll come across the term oil canning.

If you havent seen oil canning or heard the phrase before, you probably have no idea what it is or why it happens. But if you already have or want a new metal roof, the possibility of oil canning is something you need to know about.

Thats why were going to break down what oil canning is.

The team at Bill Ragan Roofing takes pride in educating you on the good and the bad of the roofing industry. We understand the importance of sharing our expertise with homeowners to ensure they go into their roofing project well informed and confident with their decisions.

Install The Metal Panels On A Leveled Consistent And In

An uneven roof deck, whether its made of metal, plywood, or oriented strand board , is one of the most common reasons oil canning occurs. If the metal panels are installed on top of one that bows or is inconsistent in its plane, stresses are inflicted on the metal as it tries to conform to this uneven surface. Always use the proper methods to ensure the roof deck is level before any panels or accessories/components are installed.

You May Like: How To Start A Roof Cleaning Business

Ways To Prevent Oil Canning

Now that you have learned about the various causes that can give rise to potential oil canning. You must be wondering what can you do about it and how can you make your metal roof look good again. In the next section, we will discuss just that.

Find A Heavier Metal

A good way to prevent the issue of oil-canning of metal panels is to buy a metal that has a thicker gauge. A metal gauge is a term used to describe the thickness of a particular metal. The thicker the metal, the lower will be the gauge number associated with it.

What a heavy metal will do is reduce the bending and wrinkling, since it is stronger and hard to bend.

Use More Striations

In order to keep Standing Seam and other flat panels looking their best, striations are often added to these metal panels. These striations are in the form of ridges, ribs, or waves. They are used to reduce the flat spaces on the metal roof. These ribs can play a role to reduce the appearance of oil canning of metal panels.

Opt For A Lighter Roof Panel Color

Your color choices can also have an impact on the extent of visibility of the oil canning effect. For example, the canning waves or creases are more obvious on darker-colored panels. On the other hand, they are less noticeable on white or lighter colored panels.

Should I Still Use Metal Roofing If There Is Oil Canning Present

While you can take precautions to prevent an oil canning problem, there is no way to guarantee that it will not occur as it is inherent in metal. However, there are several factors, including product type and color, that can help disguise its presence.

Oil canning is merely a cosmetic issue that is not even always noticeable. It has no impact on the longevity, durability or performance of your roof. The potential for it should not impact a decision to invest in a roof that will give you 40-60 years of value.

Besides being one of the longest lasting roof materials, metal offers many other benefits.

Recommended Reading: How To Apply Silicone Roof Coating

Oil Canning: What Is It And How Can I Prevent It

What is it?

Oil Canning is when sheet metal products seem to bow or wave outwards especially in the flat part of the panel. It takes away from the aesthetic of the cladding so it is best to do everything possible to prevent this effect.Many things can affect oil canning of a panel including:

- Sheet thickness

- The span of the flat section of the panel

- Thermal expansion and contraction

- Settlement of the structure

Heavier gauge panels will be more resistant to oil canning than lighter gauges. Panel structures can also be optimized to reduce it. Panels with minor ribs, striations and shorter flat spans will be more resistant than other profiles. As well, new fastening systems like the Floating Clip System can help to reduce the number of fasteners needed to install cladding. This results in more flexibility of the panels to allow for thermal expansion and contraction. The colour of the metal can also help to minimize oil canning visibility .

How can I prevent it?

As manufacturers of metal cladding, we take every precaution to minimize the the risk of oil canning. However, during installing there are some additional steps that you should take as well:

- Always lift and carry panels by the long edge to prevent twisting and damage to the panels

- Never over-engage panels

- Always use proper installation procedures to install panels in order and fasten in one direction

- Be aware of the proper places to step during installation to not damage the panels

Final thoughts

Your New Standing Seam Metal Roof Will Last Longer Than A Screw Down Metal Roof

When you invest in a new roof, you want to get the most out of it. A standing seam metal roof is one of the most durable and long-lasting roofs on the market.

With that in mind, a standing seam metal roof lasts longer than a screw down metal roof.

As long as its properly installed and your attic is adequately ventilated, theres no reason you shouldnt get at least 30 years out of your standing seam metal roof. Under the ideal conditions, a standing seam metal roof could last for 50 years.

On the other hand, you could get 20 years out of a properly installed screw down metal roof with no maintenance. With periodic maintenance, you could possibly stretch it to 30 years.

Recommended Reading: How To Replace Roof Vent Boot

Structural Changes That Put Tension On The Panels

This occurs when the home or building that a metal roof or wall system is installed on changes, moves, or experiences something that makes it different from its original form. Oil canning can happen if there is enough of a change that it puts tension or stress on the metal panels. This is a little more infrequent of an occurrence but is possible if subjected to extreme weathering that affects building structures.

Hire The Best Metal Roofers In Denver Colorado

From the above blog, it is clear how important it is to install the metal roof in a perfect way. A proper installation process can drastically reduce the possibilities of future issues such as oil canning.

If you also do not want any mistakes in installing your metal roofing system that it is better to contact a professional roofing company such as Sol Vista Roofing. We are the No.1 contractor in Denver. Our team has a combined experience of more than 20 years.

We offer high-quality metal that can provide your roof with a longer lifespan with fewer issues. Our team is properly trained and ensures that the process is done seamlessly. Contact us today at to get a perfect metal roof and reduce the oil canning effects.

Read Also: Can A Roof Be Replaced In The Rain

Considerations During Product Selection To Minimize Oil Canning In A Metal Roof

Because its purely aesthetic, oil canning isnt a concern in many building applications. But for high-slope or high-visibility projects where oil canning would be problematic, there are some steps that can be taken during the product selection phase to reduce the phenomena of oil canning.

It is possible to introduce oil canning during the panel manufacturing process. So its incredibly important to select a panel manufacturer with trained technicians who understand the importance of ensuring that equipment is properly maintained and calibrated before production begins. For this reason, some specifiers do not allow panels to be site-formed. Others will allow panels to be produced on-site but include rigorous quality standards in their specifications regarding operator training and machine maintenance.

To minimize the effect of oil canning, panel widths can also be reduced. Standing seam panels are typically 12-24 wide. Since oil canning is more common in wide/flat areas, its logical to assume that panel widths of 24 would be the more prone to oil canning. So going to a narrower panel width can certainly help. With that said, going to narrower panels typically comes with both a higher material and install price as contractors are handling more panels and accessories so installation time is slower.

What Is Oil Canning

Oil canning is defined as the perceived waviness of a metal panel and is an inherent characteristic of light-gauge, cold-rolled flat metal products. In other words, its a visual phenomenon that makes metal panels look wavy or somewhat distorted, especially in the broad, flat areas of a metal roof or wall system. Oil canning can occur with any type of metal material used in construction, including:

The severity of the waviness varies quite a bit depending on the color, finish, time of day, time of year, or even just the angle the metal is viewed from, which is why no real concrete method or scale for measuring it exists.

A silver lining of oil canning is that, if it does occur, its just a cosmetic surface-level issue and doesnt affect the structural integrity of the panel system. This is why nearly all warranties, whether it be weathertight, substrate, or paint warranties, dont include oil canning as a viable claim because there technically isnt anything that would cause the roof to fail for that reason alone.

Luckily, there are known causes and ways to minimize the chance for oil canning, which we will define and discuss next.

You May Like: How To Repair A Roof On A Camper