Which Is Better 7/16 Or 1/2 Osb For Roof Sheathing

7/16-inch OSB is the most common choice for modern roof sheathing, but that does not mean you should use it in every build. This is only slightly smaller than ½-inch roof sheathing, but some people say there is a noticeable difference in using it for roof sheathing because of its weight-bearing potential.

If you plan to build something that requires extensive weight-bearing, choosing ½-inch paneling is a better option because of the additional support.

Also read if you can choose 1/2 Or 5/8 Roof Sheathing

Is Roof Sheathing Necessary

Roof sheathing makes your roof strong, and that makes it necessary for almost any home construction. A building can only be complete when it has a roof over it, but a roof is not quality if it is not strong.

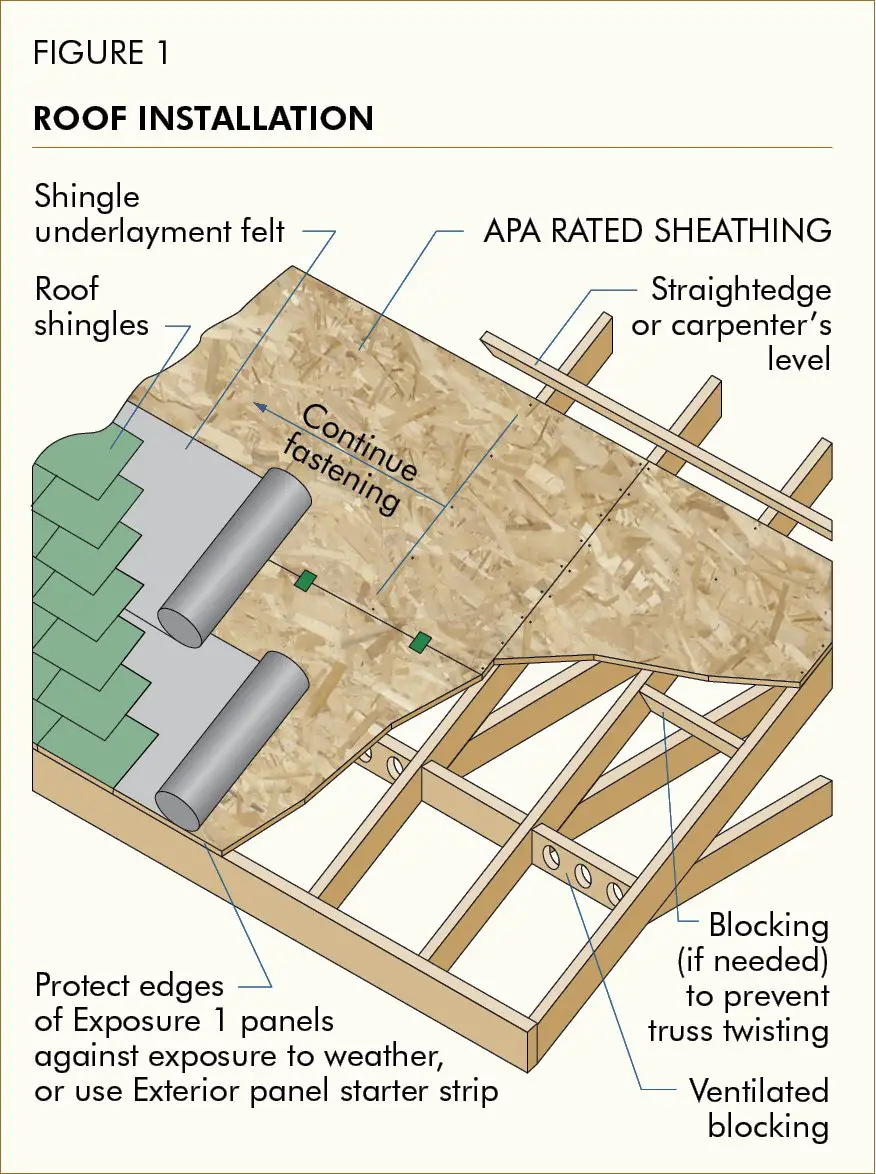

The roofs structure is comprised of rafters and trusses of different sizes, e.g., 3×2, 4×2, and 6×2 wooden frames that are spaced on intervals of between 16 and 24 apart in both length and breadth.

Most roofing materials come in the form of asphalt shingles or tiles, and because they are smaller in size and are laid nearby, the tiles wont have the base to apply on if the roof does not have a sheathing.

But as much as homeowners only think of a roof sheath as the surface for holding shingles and laying out tiles on the roof, a roof sheathing has several benefits as an added advantage:

Will Cold Climates Require A Thicker Roof Sheathing

Whether youre sheathing a house or a shed, you should always keep the weather in mind while deciding on the suitable thickness for the roof sheathing, especially in the winter.

This is because winter is where the majority of the rain and wind occur, which are the true test of the structural integrity and durability of the roof sheathing.

Moreover, in northern states, winter is often accompanied by snow, which puts a tremendous load on the roof in terms of sturdiness and moisture resistance.

Another specification that the APA includes on the label of the roof sheathing is the maximum load it can support, which is usually measured by pounds per square foot or psf.

If you live in an area where snow falls regularly, its always better to err on the side of caution and go for a roof with a load tolerance of about 50 psf or higher.

Of course, panels rated at 50 psf or higher are usually thicker than average roof sheathing options, and they usually cost a bit more, so you have to keep that in mind.

Read Also: How Much Is A New Roof In California

What Type Of Osb Is Used For Roofing

Half-inch OSB is suitable for rafter spacings up to 24 inches, whether or not the edges are supported. Sheets must have a 1/8-inch expansion gap between them and should be secured to the rafters with 8d nails. The nails should be spaced 6 inches around the edges of a sheet and 12 inches in the middle.

What Is The Ideal Thickness Of Shed Roof Sheathing

If youre roofing a shed, you might consider a sheathing substrate of about 5/8 inches. This thickness is considered the sweet spot at which the roof sheathing wont cost you as much, remain easy to install and provide you with a pretty decent level of durability.

When it comes to sheathing material, you should consider OSB or plywood. These materials are excellent for the job, although OSB is preferred over plywood because it holds up better and is easier to install.

Moreover, strand board is more affordable than plywood, making it an ideal choice for those on a tight budget who dont want to spend a lot of money on roofing a shed.

However, if youre worried about rain penetrating your roof, plywood would be a better choice for you because it dries up much quicker than OSB and returns to its initial thickness when it dries up.

Read Also: How Much Is A Shingle Roof Per Square Foot

Roof Sheathing Spacing And Thickness

My wife and I recently had a home fraimed by the Amish who supposedly have excellent workmanship. However, the house has terrible workmanship and we are not satisfied. The house was built with very bad lumber . The roof rafters are not straight and the lumber is twisted.They cut the roof rafters to short and scabed nails in to make them hold with 3/4 gaps betwen the rafters and main ridge beam The rafters are on16 inch centers and 7/16ths sheathing was used on the roof with no spacing between sheathing. The roof has 24 inch overhangs and if you step out onto the overhang you feel as if you may fall through.I have fired them and I am going to finish the house using another builder They fraimed the house with no contract or money down. We close on the construction loan in a week so I need to find all problems and do a labor and materials adjustment My question is: Should the roof rafters be replacedand should sheathing have spacing between sheets to prevent roof buckling? Also, is 7/16ths sheathing thick enough for 24 inch overhangs? These Amish guys have me stressed out!!!! We have waited years to do this and I want done right Thanks for any replys.

A little more information to flesh out your answers.

16 oc “trusses”-trusses, not rafters right?

If 16” centers, how’s the overhang 24″? It may project 24” but the framing centers are still 16′, no?

thanks.

Become A Gba Prime Member And Get Instant Access To The Latest Developments In Green Building Research And Reports From The Field

I am zone 6/7. Everyone including myself in my metro and sorrounding will typically use 1/2″, I have come across 3/8″ plywood on homes from the 80’s. Typically if Im in northern WI zone 7 5/8 is the norm regardless of roofing type for the heavier snow load.

I use 1/2 under standing seam with no problems, we get maybe 60″ of snow a year average.

Tony, builders sometimes denigrate the building code, and it’s not perfect, but a lot of smart people have spent a lot of time developing prescriptive recommendations for almost all of the typical construction situations. Table R502.3.2.1.1 in the IRC provides guidance on roof sheathing: , and manufacturers’ literature has more information. A lot of it depends on the live load where you are, which includes wind and snow loads. If you use edge clips you can use a thinner sheathing. In my zone 6 location with a 50 psf snow load, I use 5/8″ sheathing on both 16″ o.c. and 24″ o.c. roofs. It is more than required by code but provides a nice stiff surface.

T and Michael,

Any thoughts on OSB vs plywood under metal roofs? Any concerns about holding power of screws into OSB? I’ve always used either 1/2″ or 5/8″ plywood.

Michael, Speaking of underlayments, what do you, and others, recommend between OSB and standing seam metal in zone 6? Small cabin, 4/12 pitch, vented. Tony

Recommended Reading: How To Build Gable Overhang

The Gaps Between The Framing Matter Too

The average roof sheathing thickness is also heavily dependent on the spacing distance between rafters or trusses.

The further your trusses or rafters are spaced, the thicker the layer of the roof sheathing needs to be.

For example, the most common spacing between trusses is about 24 inches, while the most common for rafters is about 16 inches.

Luckily, the APA regulates the maximum distance that a panel can bridge between the gaps, stamped on the roof decking in the form of two numbers divided by a slash.

For example, if a roof sheathing panel has a stamp that says 24/0. This means that the maximum gap it can hold between framing is about 24 inches.

What Is A Pyramid Roof

As you might guess, this is a type of roof that is shaped like a pyramid.

A type of hip roof with no gables or vertical sides, pyramid roofs are usually used for smaller homes like cabins and bungalows, or sheds, garages, or other outbuildings.

Pyramid roofs are popular in hurricane or windstorm prone areas, since they are extremely wind resistant.

They also provide good ventilation and extra storage or attic space, or the interior can be left open for a high ceiling.

The overhanging eaves of a pyramid roof help to improve energy efficiency as well.

Note that pyramid roofs may be costlier to construct and maintain due to the complexity of the roof design, but they do provide the aforementioned advantages.

They can be crafted from nearly any common roofing material including asphalt shingles, composite shingles, metal shingles, slate, clay or concrete tiles, or wooden shingles or shakes.

Dont Miss: Roof Replacement Cost In California

Don’t Miss: How To Extend A Metal Roof Overhang

Plywood Is Layers Of Wood

Plywood is made with three or more layers of thin wood glued together with the grain alternating. It is typically made in 4-by-8-foot sheets, although longer panels are available for special purposes. It is a flexible, durable, inexpensive covering for roofs because each panel will cover 32 square feet. It comes in multiple thicknesses from 1/4 inch to at least 1 inch those above 1/4-inch typically have five layers of wood. The material cuts easily using a circular saw or handheld cutting tool equipped with a 3-inch multipurpose carbide wheel which lends to its popularity.

Oriented Strand Board Decks

Oriented strand board decks have quickly become a preferred option for modern roof sheathing. This is largely because the product is very durable and less expensive than many other sheathing options.

OSB has been around for more than half a century. These days, more than half of all new home construction in the U.S. includes OSB decking. The synthetic material is made of tiny fragments of wood. Each fragment is bound together by a special resin adhesive. When properly installed, OSB provides good sturdiness, strength and uniformity at an affordable price. This is one of the reasons its so widely used throughout the industry.

Don’t Miss: Skylight Installation Metal Roof

How Do I Know If My Roof Is Sheathing

Divide the total roof area by 32 to get the number of sheets you will need to cover the roof. A typical 4 foot by 8 foot sheet of plywood covers 32 square feet. If your roof area is 1,600 square feet, 1,600 divided by 32 will mean you need about 50 sheets to cover the roof. Add 10 percent to allow for waste.

There Is No Standard Roof Sheathing Thickness

You should keep in mind that roof sheathing thickness isnt standardized. However, the Engineered Wood Association APA still standardizes the quality testing of the sheathing but not the thickness.

Instead, some standard roof sheathing thicknesses are agreed upon for being the perfect balance between durability, ease of installation, and budget.

For instance, the most commonly used thickness will be about 5/8 inch thick when it comes to strand board roof sheathing.

On the other hand, plywood roof sheathing is usually more durable, so a thinner board will still do the trick, which is why about 1/2 inch thick boards are the agreed-upon standard for plywood.

You May Like: How Much Does Shingle Roof Cost

Composite Asphalt Shingle Roof

Composite shingle roofing is the most popular of all roofing materials, found on more than 80 percent of all homes. Composite shingles use either an organic or fiberglass base that is saturated with asphalt, coated on the bottom side with asphalt, and the exposed surface impregnated with small chips of slate, schist, quartz, or ceramic granules.

The vast popularity of shingles owes to the relatively low cost, easy installation, and decent life expectancy. These roofs are normally installed by professional crews, but installation is not out of reach for a skilled DIYer.

Choosing The Thickness Of Your Roof Deck Based On The Application

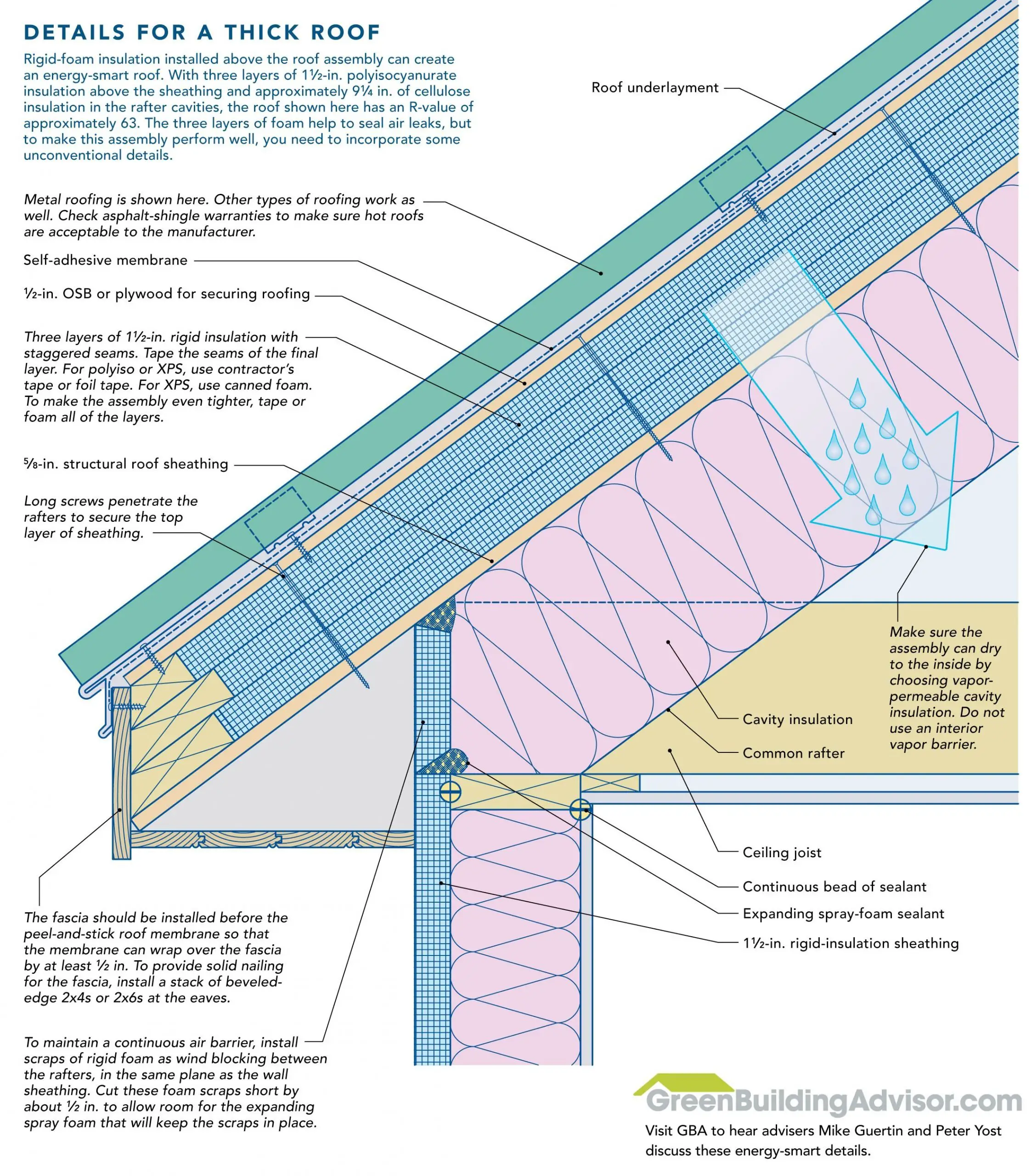

The thickness of your roof covering is determined by a variety of factors, including the type of roof, roofs inclination, climate condition, and material design codes.

- Roof Decks for Cold Environment

If your roof does not have suitable dimensions, climate changes may have an impact on its durability. In places where there is seasonal snow, the weight of the snow is another factor to consider before purchasing panel boards. All forms of roof covering have a marking that specifies the maximum spacing between structural frames.

The maximum permitted loads that the board can withstand are listed beneath the label of the sheathing material. This can assist you to determine the thickness of roof materials. In regions with snowy weather and frequent heavy rains, solid sheathing panels are suggested for all forms of roof installation.

It is better to choose 1×6 boards so they would not tend to expand and contract when subjected to different weather conditions. Roof boards must be placed with a secure corner joint, but with a minimum of 1/8 inch for the expansion space. On the trusses, the corner junctions should be balanced and aligned. When constructing mineral-surfaced sheet covering, rectangular shape planks are not suggested because single boards can bend, causing the material to fracture.

- Standard or Garden Shed

- Replacing the Roof Materials

Read Also: Average Shingle Roof Cost

Many Factors Affect Thickness

The thickness of plywood used for roof decking depends on the roof slope, the spacing of rafters and the weight of other material to be put over the decking, as well as the design “load” the amount of pressure exerted by various forces and the weather, especially weight of snow or ice accumulations. The wider the rafter spacing, the heavier the shingling, the lower the slope and the heavier the weather load, the thicker the plywood will have to be.

What Is A Roof Deck

It can be argued that the roof deck is the backbone of the allroofing systems. It is found between the structural components, like yourtrusses, and the insulation and waterproofing layers. Essentially, the roofdeck is the part of the roof on which everything is placed. It needs to bestrong enough to hold the weight of the roof, while being able to cope withsome give. There are various types of roof deck materials to choose from butthe commonly used materials for residential are Plywood or Tongue & Grooveand on commercial roofs, steel, concrete and cement.

Don’t Miss: How Much For Shingle Roof

What Size Plywood Should You Use For Your Roof

The industry offers a thickness of anywhere from 5/16 inch to ¾ inch. So, what size plywood should you use for your roof?

There are several factors to consider:

- How the roof is designed.

- The spacing of the rafter.

- The expected load.

A half inch thickness is considered to be standard in a lot of areas and it should work just fine considering that its deemed okay by the roofing contractor after considering the things above. Its the standard for spacing of 24 inches in the rafter, although as mentioned, a 5/8 inch thick is more ideal. You might be tempted to choose a ¾ inch thickness although its unnecessary in most cases.

You can get plywood sheets with a length of up to 10 feet. The standard width is 4 feet.

Talk to a professional so that the factors will be properly considered so you can make the right choice on the best wood.

When Sheathing A Roof Is Plywood Or Osb Best:

In an ideal world you would schedule your roof construction during a dry period if possible. Depending on your roofing design, allow time for membranes to be installed, or at the very least get a tarp on it before it sees any rain. Roofs are probably the better of the applications for OSB if you take steps to keep it fairly dry. Severe wetting may lead to swollen edges – that may be noticeable with asphalt shingles, but less so with other materials.

Don’t Miss: Hydro Stop Roof Coating Cost

What Is The Best Roof Sheathing

Oriental Strand Board is currently the best roof sheathing. The future is OSB.As time goes, new roof sheathing brands come into play. As industry players are looking at the affordability and longevity of roofing materials, one material will try to outdo the other.

When a product enters the market, it is presented in the best forms for homeowners and builders to choose from a variety.

In the recent past, 50% of builders and homeowners preferred OSB over the rest of the roof sheathings available today.It is because OSB offers the same quality as plywood and at a much lower price.

But plywood, as much as it is expensive, still overrides OSB as a superior roof sheathing material.

One is because the plywood is much stronger than the latter, and two is because the plywood is also superior in protecting your roof against water and moisture, which are the greatest enemies to sound roofs.

The conclusion is that the plywood takes home the trophy as far durability and integrity of the roof are concerned.

Also, see our article on the energy-efficient radiant barrier roof decking.

How Do You Secure A Railing To Siding

Hold the bracket and template at the marked location on the wall. k the location of the mounting hole onto the siding. Drill pilot holes into the siding and sheathing underneath. Attach the bracket and template to the wall using stainless steels screws long enough to penetrate at least 1 inch into the sheathing.

You May Like: Extending A Roof Overhang

Diy Or Hire A Professional

Speaking of DIYers, should you do the sheathing yourself or should you hire a professional? It might be tempting to do it yourself especially if youre looking to save money. To know the answer to this question, answer these simple yes or no questions:

- Do you want the best results?

- Do you want to stay away from potential accidents?

- Do you want to save money in the long run?

If you answered yes to these questions, then you need to hire a professional. It doesnt matter how experienced of a DIYer you are. A professional will always do a better job provided that you hire the best one for the project. After all if youre better than them, you should be getting paid for it, right? Besides if youre not satisfied with their job, a professional will make it right to ensure the best results.

More importantly, hiring a professional will keep you away from potential accidents. Working on the roof is dangerous. You can easily slip and/or fall. You can create more damages. Simply put, its not safe.

In addition, hiring a professional can help you save money in the long run. Since they can ensure the best results, you will get your moneys worth. The job will also be done right which will minimize mistakes and wastage.