How Often To Replace Screws On Metal Roof

How Much To Replace A Flat Roof Florida Roof top ventilators replacement Bearings Repairing a leaking roof is important to maintaining your home. leaky roof repair is a labor From the top of the roof, remove the damaged roof vent. First, use the pry bar to pull out nails Replacement Roof Antenna For 2014 Hyndia Tuscon NHTSA rates crash-tested vehicles by

Roofing Replacement Abd Repair Companies In Augusta Ga Area Trying to decide whether to repair or replace your roof? HouseLogic gives tips to help you decide on whether you need a new roof or a repair will do. Deciding whether to repair or replace roofing is largely an exercise in timing you dont Roof Top Ventilators Replacement Bearings Repairing a leaking roof isCost To Replace A Ridge Roof Vent Weather, debris and time can wreak havoc on your mobile home roofing. In addition to the elements, roofing only lasts for so long, which means youll likely have to consider mobile home roof replacement at some point. Learn more about what Tnha Roof Replacement Bid At some point, most homeowners will need to think

At some point, most homeowners will need to think about getting new roof tiles. Roof tiles can be quite expensive, but you have to make sure you get the best quality products for the job. Check below for tips on how to get replacement roof

Roofing Screws Metal To Wood

The most common type of metal roofing fasteners are metal to wood roofing screws. Fastener manufacturers usually specify pull-out strengths for a variety of different types of wood as not all wood is the same. This helps to determine the right fastener for your project.

An example of a fastener for a wood substrate is the #9 metal to wood screw or the #10 metal to wood roofing screw. These screws have an extra sharp self-piercing point that can penetrate 20-29 gauge steel sheeting and then into the wood without pre-drilling, slipping, or damaging the metal panels.

Choosing The Screw Head Of Your Fastener

Fasteners come in different profiles that each accommodate different criteria.

For example, there are flat screws, also known as pancake screws, that are used when low profile installation is necessary. Another example are shoulder screws which feature an oversized dome beneath the head that is useful when thermal movement might distort the holes.

You May Like: How Much Are Metal Roofs For Houses

Do Screws Back Out On A Metal Roof

In the field, fasteners might get loose and fall out. To correct this, well tighten the fastener until its flush with the roof, then apply a sealer like KarnaFlex Seam Sealer over the top to protect, seal, and keep water out.

After that, the roof will be watertight. It is also a good idea to replace the screws on your roof if you see them starting to rust.

Otherwise, there is a great danger of the screw getting stuck in the skylight. If this happens, it wont be easy to take the skylight out and reinstall it later.

Youll need an extra pair of hands when doing this work, but you can complete the job in under an hour without special tools or equipment.

To ensure that your roof stays watertight after installing roofing material and putting down gravel , fill up large holes with crushed stone or concrete from a nearby store.

The best thing to do is to buy aluminum, steel, or a titanium screw with replaceable heads. Theyre available at most pool supplies stores. The screws come in different forms, so you can use four links to buy your hook.

If you ever find out that a screw head breaks off inside the threading of your solid material and it is not possible for you to remove it, you can be sure to use our special insert and extractor tool for this purpose.

Whats The Correct Screw Length For Metal Roofing

If your fasteners arent long enough to penetrate through all of your material, its safe to say youre not going to have a successful installation. The right fasteners must not only be long enough to go through the material, but you must also take into account the length of the drill bit if you are using self-drilling screws.

Most importantly, you want at least one inch of screw penetration into the material that you are fastening to.

The length is usually rounded up to the next half or quarter inch to ensure the fasteners are long enough. Keep in mind that the longer the screw, the more torsional strain is produced during driving. Sometimes this can cause the fasteners to break during installation.

Read Also: How To Paint A Metal Roof With A Roller

How Often Should Metal Roof Screws Be Replaced

There is no definitive answer to this question as it depends on a number of factors, such as the type of metal roof, the environment in which it is located, and the level of maintenance it receives. However, as a general rule of thumb, metal roof screws should be replaced every 3-5 years to ensure the roof remains in good condition.

Question : Why Standing Seam Metal Roofs Is It Worth It

We often tell customers who are looking into getting a metal roof is that even though a standing seam metal roof might cost two to three times more than a regular composition roof, once they have it on, they dont have to worry about it.

If not having to worry about frequent maintenance and repair issues with asphalt roofs is a big deal to you, standing seam is 100% the way to go.

Read Also: Does Usaa Cover Roof Leaks

Select The Right Screw Based On The Type Of Material

When selecting the material of your screws, consider the type of metals the screws are fastening into. When dissimilar metals are in contact and are exposed to moisture, galvanic action occurs.

Galvanic action between dissimilar metals can result in premature fastener failure that leaves your panels at risk for leaks to occur. Simply put, when certain metals come in contact with each other, one metal will sacrifice itself to the other.

Generally, the further apart the materials are in the galvanic series , the higher the risk of galvanic corrosion. The farther apart the metals are on the chart, the greater the corrosion will be.

Can You Pressure Wash A Metal Roof

Yes, you can pressure wash a metal roof with light pressure and hot water. A roofing contractor probably has the equipment to pressure wash your roof if you don’t feel comfortable climbing on top of your house.

If you want to pressure wash your metal roof, keep the following in mind:

- Figure out what type of roof you have: Knowing what kind of roof you have can help you wash it properly. You can walk on a flat metal roof, but be careful of slippery areas. On the other hand, you might want to clean your high-pitched metal roof on a ladder because it’s challenging to walk on it.

- Be safe: Follow metal roof safety tips when you’re working on the top of your house. You may want to invest in a harness, fall arrest protection and ladder with stabilizers to prevent slipping off your property. It helps to have a friend or family member spotting you on the ground in case of an emergency.

- Use the appropriate pressure washer: You probably want to use a hot pressure washer with a 40-degree tip, especially if you have a flat roof. The hot water and precise angle can remove debris buildup and grime.

- Avoid using too much pressure: Even though a pressure washer is safe to use for a metal roof, too much pressure could damage it.

You May Like: Can You Put New Roof Over Old Roof

Why Its Important To Maintain Your Metal Roof

Providing your metal roof with the proper maintenance is essential to maximizing its lifespan while preserving its appearance. In this section, well discuss three reasons why annual maintenance is so important. Continue reading to learn more about the benefits of caring for your metal roof and ultimately your home.

Should I Replace The Screws In My Metal Roof

Should I replace the screws in my metal roof?

A metal roof must have screws to hold the metal panels in place. These screws become loose or back-out with the expansion and contraction of the overtime. This is a sign of age on a metal roof and must be addressed to prolong the life of your roof. Replacement with caulk is first alternative, but a thorough evaluation is necessary to determine, costs, convenience, safety, and appearance concerns. A commercial roofing expert can help determine our best course of action.

In most scenarios, we are able to repair your roof promptly and efficiently

We make sure to be fully insured and covered in all states we work in before starting every project.

Recommended Reading: How To Sell Roof Jobs

How To Replace Metal Screws On A Roof

How to Replace Metal Roofing Screws. 1 Step 1 Examine the Roofing Screws. Check out roofing screws on Amazon. Roofing screws come in various shapes and sizes but with roofing screws, the 2 Step 2 Attach Sock to the Drive Fastener. 3 Step 3 Install the Screws.

Do you need a grommet for roofing screws?

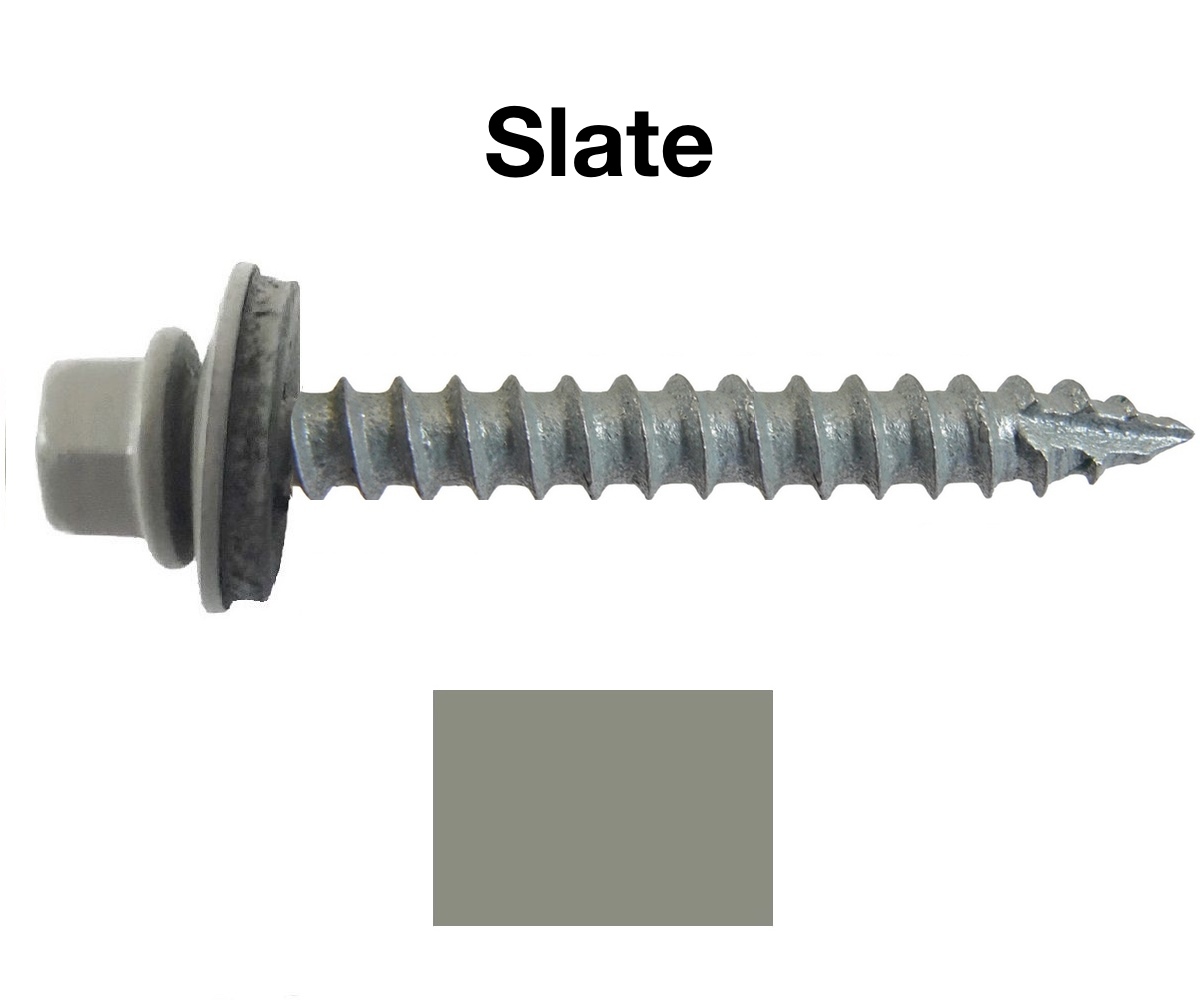

Each screw should also have a metal washer which should match the roof. Below this there should be a rubber seal or grommet. Do not attempt to install them if this is not the case as you will end up with a leaking roof. Attach the correct sized socket for your roofing screws onto the electric drill.

How often should you check your roof screws?

You ideally need to check your screws twice a year. You need to inspect the fasteners for any movement in the screws or in the sealant fixture. This is imperative if you have any fasteners which are exposed. Check the fasteners to ensure that they are tight too because movement can easily force screws out of their holes.

Can a screw in a roof cause a leak?

Installing the screws in the lower portions of the roof can cause leaks, in spite of the rubber seals. When installing each screw, use the drill on a low power setting, carefully driving it in. When it starts to penetrate the metal, you can speed it up a bit.

Choosing The Right Diameter For Your Metal Roofing Screws

The diameter of the screw is measured by the diameter of the shank. The higher the number, the wider the screw.

Choosing the correct screw will vary based upon the local building codes, climate, contractor preferences, and the engineering specifications of your job. Every job will be different and every screw has different pull-out values. The best we can do is to give you some general guidelines.

Here are the most common screw diameter sizes:

- #9 & # 10 – These are the most common sizes for metal to wood screws

- #12 – This is the most common metal to metal screw

- #14 – Wider screw thats used in areas with heavier snow loads

Recommended Reading: Can You Put A Roof On In The Rain

How Many Metal Roofing Screws Will A Typical Roof Use

The number of fasteners on any metal panel roof is dependent upon several factors – panel profile, purlin spacing, as specified by the panel manufacturer. Generally, fasteners are installed on one side of each rib in the flat and on every purlin, typically 2′ OC on a roof. At the roof ends or eaves, fasteners are often installed on both sides of the ribs. Additionally, sometimes the side laps are stitched as well by installing fasteners in the ribs where the panels overlap.

Overtightening Or Undertightening Can Both Result In Leak Points

Sinking screws to fasten a metal roof doesnt sound like a very complicated process, so many well-intentioned folks just assume they can take on metal roofing installation as a DIY project. The problem with this assumption is that if you dont have specific training and experience in this area, you could actually end up doing more harm than good. One of the most common errors revolves around overtightening or under-tightening the screw fasteners.

Most tend to err on the side of overtightening. Its a natural reaction to simply try and sink the screw as far down as it will possibly go. The tighter the screw, the more secure it must be, right? Unfortunately, that isnt always the case. The problem with this approach is that it overcompresses the washer, and thus creates too much stress. This can cause the washer to fail prematurely or worse, you could break the washer right off the bat. Overcompressed or broken washers can easily result in leaks.

You dont want to overtighten, but you really dont want to undertighten your screws, either. A screw thats underdriven doesnt create a proper seal for the washer, and that can result in leaks, too. If you can still spin the washer after youve put in your screw, thats a good indication that the screw is undertightened. A professional installer is able to avoid both extremes by utilizing a specialized screw gun thats set to exact speed and torque specifications for specific metal roofing gasket fasteners.

Don’t Miss: How Do You Install A Tin Roof

Metal To Metal Roofing Screws

There is more than one type of screw that you can use when you attach to metal or steel. The right screw is based on the application and the thickness of the steel.

Types Of Metal To Metal Roofing Screws

- Screws that fasten the sidelap of the metal panels or attach the trim and flashing.

- Screws that attach to light gauge metal such as metal purlins.

- Screws that attach to heavy steel joists, I-beams, or steel tubes.

Who Is Installing The Roof

Another way to determine the type of roof is to know how you want the roof installed on your property.

- Choose standing seam if: You want to hire a qualified and skilled contractor with standing seam metal roof installation experience who has their own rollformers, seamers, and other required tools.

- Choose exposed fastener if: You want to do the installation yourself , or you want to hire a less expensive contractor with experience installing exposed fastener systems.

You May Like: How To Cover Leaking Roof

Screws Are The Best Way To Hold Your Roof Panels In Place

Screws tend to be the best way for you to hold any of your roof panels in place. Never use nails when repairing your roof. Screws wont bend and they wont work themselves loose when expansion or contraction takes place. Its also a good idea for you to use self-tapping screws that come with thin washers as this will give you a better seal. When a screw looks compromised, arrange to get it replaced. Only use screws that have been approved by your roofing manufacturer if you want to make sure that the repair is going to last.

Myth : Poor Performance In Inclement Weather

12% of homeowners said they worry metal roofing would perform poorly in bad weather.

Fact: When compared to other roofs, metal consistently demonstrates superior performance in a wide range of severe weather conditions.

In fact, the majority of homeowners who end up installing a metal roof, do so largely because of the level of protection it affords when bad weather strikes.

In the Northern states that get a lot of snow, ice and hail, metal shingles and standing seam roofs are unbeatable in protecting the home from ice dams and hail damage, which can cost thousands of dollars. They shed snow extremely fast, prevent water from backing up on the roof and leaking inside your home.

In the Southern states, where homes are constantly exposed to the sunâs ultraviolet radiation, metal boasts the best energy efficiency. It will save you hundreds of dollars by cooling your home, because it reflects heat rather than absorbs it, like an asphalt shingles roof does.

In the areas that are prone to wildfires, metal roofs protect homes from catching on fire. Metal is non-combustible and carries the highest fire rating of any material in the industry.

In the regions that are exposed to hurricanes, metal will protect your home from suffering major damage, because it boasts at least a 140 mph wind rating. This means your roof will not be blown off or require extensive repairs, which as the case with asphalt shingles.

Read Also: How Much To Charge For A Square Of Roofing

What Are Metal Roofing Screws Made Of

The fasteners are made of various metals and combinations of metals all to achieve different results. The standard fasteners are a carbon steel base with plating or coating to provide some level of corrosion resistance. For the optimum protection against corrosion, Long Life fasteners should be used. These are stainless steel and ideal for aluminum panel attachment. Generally, an all stainless screw does not consistently pierce or drill a steel panel on its own. For steel panel attachment where complete corrosion resistance is required, a bimetallic fastener would be the option. Bimet fasteners are available for both wood and steel structure applications. The head and shank of these fasteners are stainless with a carbon steel point that allows the fastener to penetrate a steel panel and drill into both wood or steel substrates.

Choosing The Correct Fastener For Exposed And Concealed Panel Systems

The type of fastener you use depends on whether you are installing exposed fastener panels or concealed fastener panels. Wavy corrugated and R Panel are examples of exposed fastener panels. Standing seam or flush wall panels are a concealed fastener panel.

When installing exposed fastener panels, fasteners with rubber sealing washers are used to increase the weathertightness of the panels and keep water out.

Concealed fastener panels use fasteners with a low profile head to avoid contact with the underside of the roofing panel.

Concealed fastener panels that use clip attachments, such as snap lock standing seam, generally use pancake head style fasteners. A system that does not use clips, such as nail strip standing seam, uses extra low profile style fasteners.

You May Like: Should Flashing Be Replaced With New Roof