Why Is 24 Gauge Metal Roofing Better For Climates With Snow

If you are installing a metal roof in a harsher climate that experiences snow, heavy winds, and hail, it is best to use a thicker gauge. A 24 gauge metal roof has more strength, is more impact resistant to hail, can handle higher winds, and heavier snow loads compared to a 26 gauge metal roof.

If you are installing a metal roof in a milder climate, using a 26 gauge metal is more appropriate.

Corrugated Metal Roofing Thickness

There is not a standard gauge for an exposed fastener metal roofing system. The primary factor in determining the correct gauge is based upon whether the panel is installed on a solid wood substrate or spanning from support to support.

Residential Metal Roofing Over A Solid Wood Substrate

This is the most common type of residential metal roofing installation. You will have a solid wood substrate, roofing underlayment, and then the panel gets installed on top of these. With this type of installation the panel does not have to support any weight.

Either 24 or 26 gauge are appropriate for this type of metal roofing installation. Each has its pros and cons that are discussed later in this article.

Metal Roofing Spanning From Support To Support

This is a roof that has either metal purlins or wood beams spaced at different distances. The panels will need to support themselves and any load that it will have to carry such as a snow load, people walking on it, etc. It will also have to withstand the wind uplift.

24 Gauge is capable of greater spans and load capacity when compared to 26 gauge. However, every job is different and load charts and uplift charts are used to determine which metal roofing gauge will handle all of the load requirements.

How Much Does It Cost To Install Roof Decking

The price of roof decking can vary significantly based on many factors. The thicker the sheet is, the more expensive it is. Again, considering that one sheet covers 32 square feet, you can expect to pay anywhere from $60 upwards to $100 per single sheet of plywood.

For an average-sized home with a roof of 2000 square feet, this overall estimate ranges between $3600 and $6000. Also, its essential to keep in mind that the cost of the installation itself will also vary depending on your location.

With all of this in mind, plywood is the more expensive choice than OSB. If youre working on a tight budget, you can also use regular wooden boards. They are a viable decking option but are more susceptible to leaking and water damage.

Also Check: Metal Roof Skylight

Finish With Ridge Caps And Gutters

Lastly, you can finish by installing the ridge caps and gutters. Ridge caps are metal or plastic panels that run along the roofs uppermost edge to protect it from water damage. At the same time, a gutter is a system for directing runoff rainwater away from your homes foundation. These will be the finishing touches and give your new roof nice clean lines and no exposed seams or edges.

Metal roof installation can be tricky if you dont know what youre doing, but thankfully its not too difficult for homeowners who are willing to put a little time and effort into the project. However, due to the immense specifications of installing metal roofing, we always recommend you call the pros.

Northface Construction offers comprehensive metal roofing installation, rehabilitation, and repair. Were your local experts that will provide your house the update you deserve while boosting curb appeal and the value of your home. Contact us today if you want to sit back, relax, and let us handle the tough stuff!

RECENT ARTICLES & VIDEOS

Can Osb Get Rained On

Your framing lumber and the oriented strand board are going to be fine. The glues used to make OSB are water-resistant because the manufacturers know that virtually no one can build a home that wont get wet before the roof and siding is applied. The OSB floors should be swept clean each day after work concludes.

Recommended Reading: Cutting Roof Trusses

Can I Use Screws For Roof Sheathing

Screws can be used for even greater withdrawal strength, but should be sized by the building designer. Staples are not recommended for roof sheathing attachment in high-wind areas. Oriented strand board is one of the most popular materials for roof sheathing.

When You Should Choose The Thinner Panel

Most homes have a layer of plywood or sheathing covered by a weather-resistant barrier. Metal panels are attached to the sheathing to keep it dry. Since they dont have a structural role, a 29-gauge panel would be more than adequate for most homes. So, if you live in an area that doesnt often face harsh weather conditions, our recommendation is to choose a thinner type of panel. However, if you live in an area that experiences hailstorms throughout the year, you might be better off with a thicker panel to prevent dents.

Don’t Miss: Cost To Reseal Rv Roof

Gauge Corrugated Metal Roofing

If you want an inexpensive metal roofing panel then standing seam is not the best option for you. The best value will be a 26 gauge exposed fastener panel in a SMP paint finish. Keep in mind though that an exposed fastener panel means that you will have thousands of screws that will penetrate the panel. Each screw is a potential leak point at a later date.

A corrugated panel will cost $1.00-$1.25 per square foot in a 26 gauge SMP paint finish.

If you would like to learn more about exposed fastener and concealed fastener panels, we suggest reading or watching: Exposed Fastener Metal Panels v. Standing Seam Systems For Metal Roofs

What Does Metal Roofing Gauge Mean

Gauge is a measurement of the thickness of a metal roofing panel. There are a variety of roofing panels that can be used to cover roofs.

Manufacturers in the United States use gauge to express the thickness of metal roof panels. Roof panels vary in thickness from 22 gauge to 29 gauge. The smaller the number, the thicker the panel.

A 20 gauge metal roof will be heavier and more durable than a 16 gauge metal roof of equal size. The durability factor is important to consider when choosing what type of material you would like for your home or business building.

Thicker panels are also better at withstanding high winds caused by storms. Thicker panels are also better at withstanding hail and even fire damage.

If you need a metal roof that is as strong as possible, then its recommended to go for the thicker 24 or 26 gauge options.

These will be heavier but can carry more weight from any snow accumulation over time- which means theyre great if your home or business is located in a colder region.

However, if youre looking for something thats lighter and easier to install then go with the thinner 16 or 18 gauge options- but know this means they may not be as strong against wind damage and it will also take longer for them to heat up during summer months so they can cool your home faster.

Read Also: How Much Is A New Roof In California

Why Switch From 29

Did you know? It is now a state law that 26 Gauge trim is required on a Residential Building. With recent law changes your product will not be considered a Florida Product Approved item unless it is the required 26-gauge.

Check out the Florida Product Approval Code for trim here: Trim Code.

But dont let the law change be the only reason you choose 26-gauge trim. Check out all the wonderful benefits this now required product provides!

Roof Sheathing Code Requirements

The minimum requirement for roof sheathing is thick. Plywood is slightly stronger than strand board, so ½ is the recommended thickness. However, OSB doesnt hold fasteners as well as plywood it must be a little thicker or at least .

Several factors determine the optimal roof sheathing thickness for added benefits like insulation.

You May Like: Extending A Roof Overhang

How To Calculate How Much Roof Decking You Need

Aside from determining how thick your roof sheathing should be, you also want to calculate how much material you need upfront. The average-sized plywood sheet of four-by-eight feet is 32 square feet. When you know your roofs total square footage, simply divide it by 32, and youll get the needed amount.

Also, make sure to calculate a 10 to 15 percent waste to ensure you dont run out of material mid-installation. This will give you a pretty precise figure on how many square feet, and therefore the number of sheets, you need to buy.

Rust Blocking Is A Balance Of Substrate Coating Type And Thickness

Manufacturers use one of two different rust-blocking coatings on metal panels, galvanized or Galvalume®. Your metal panels will have one of these two coatings applied between the steel core and the paint layer. If the paint is scratched, the rust-blocking coating is designed to prevent rust from reaching the steel core. Your 40-year warranty refers to paint only. Manufacturers may include a separate substrate warranty depending on the rust-blocking coating you choose. Ask the supplier if your quote includes a separate warranty for the substrate coating.

Read Also: Extending Roof Overhang Cost

Gauge Vs 26 Gauge Metal Roofing Thickness

Gauge numbers refer to the and each gauge has a range. When it comes to 24-gauge and 26-gauge, there is an approximate 30% difference in thickness between the two metals.

When you apply a paint finish to the base metal it will increase the overall thickness of the metal. The metal roofing gauge thickness is based upon the base metal before the paint has been applied.

Refer to the chart below for thickness ranges of each gauge.

| 1- 1.156 lbs. per square foot | .75- .9063 lbs. per square foot |

When To Use 26

- Its best to use 26-gauge metal roofs in areas which regularly experience snow, hail and wind storms.

- If you do not want to change your metal roofs again for a long time, 26-gauge is a great choice for your metal roof.

- If your building has open sides, such as a pole barn, then 26-gauge metal roofs are suitable.

Also Check: How To Get Roofing Leads Without Door Knocking

Standard Size Of Roofing Sheets

Whenever someone is looking to add metal roofing to their home, they are undoubtedly curious what size sheets metal roofing comes in. Its tough to say the exact size or length of the metal roofing panel because it differs from one panel to another depending on the metal, style, and manufacturers specifications.

Choosing shorter metal panels for your home may leave holes on your roof, which will be prone to leakages. They will not be energy-efficient and will not protect your house from harsh weather conditions.

On the other hand, if you choose metal panels that are too wide or too long, it will cost you more in labor and there will be wastage from some of the panels.

When looking at metal panels on the market, you will notice they come in different gauges like 22, 26, 24, and 29. The length and width also vary from one panel to another. You should know the precise measurements of your roof while purchasing metal panels. Knowing the correct measurements will allow you to choose the right size of metal panels for your home so that they cover your entire roof.

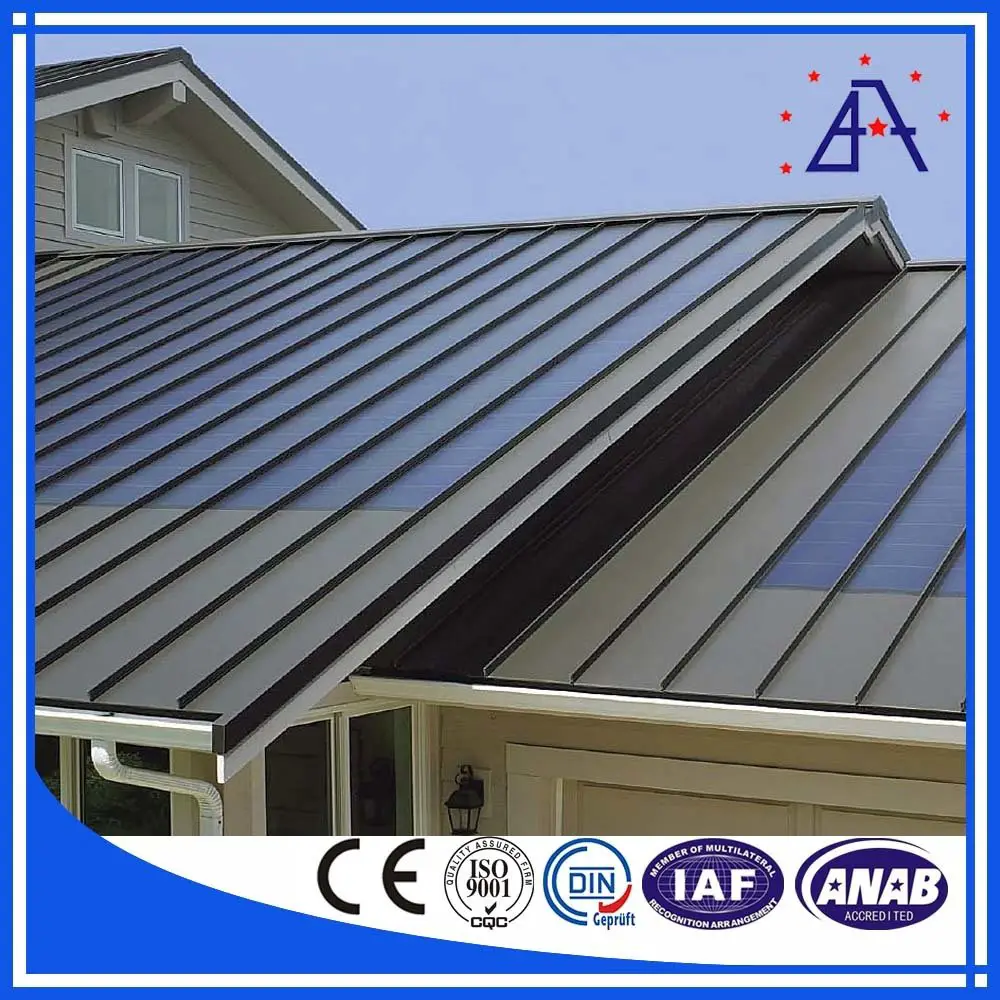

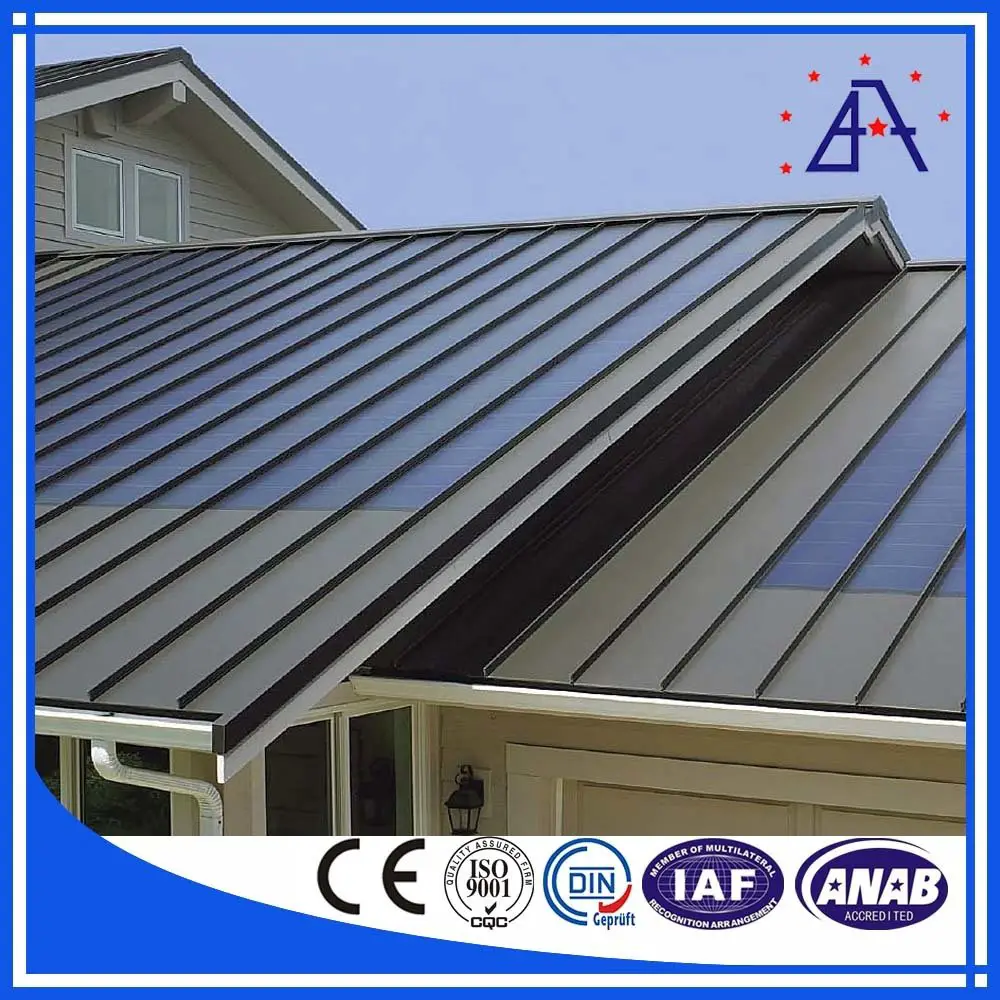

Standing Seam Metal Roof : What Homeowners Should Know

For hundreds of years, metal has been the preferred roofing material for agricultural and industrial buildings. Today, homeowners are increasingly turning to one metal roof design in particular standing seam for greater energy efficiency and a contemporary look.

The standing seam, or hidden screw, construction also provides longevity and durability that has become synonymous with metal roofs for houses. Standing seam roofs are constructed with interlocking metal panels. The seams create a seal that protects from the ravages of weather and other environmental elements.

Homeowners considering metal roofs often have questions about the advantages of the standing seam, including:

How are standing seam metal panels joined and fastened?

Installation of a standing seam roof often depends on several factors, including how the panels are manufactured. In general, metal panels are joined using portable seamer equipment, seamer caps that snap or slide in place or integrated locking systems. A system of fasteners, nails or screws is used to secure the roof onto a plywood substrate roof deck, based on the manufacturers recommendations.

What is the minimum slope for standing seam metal roofs?

At Gulf Coast Supply & Manufacturing, standing seam metal roofing panels are designed to be installed on slopes of 3:12 or greater. They can be installed on lower slopes per manufacturer directions.

What gauge metal roofing is used for private residences?

Read Also: Skylight On Metal Roof

Learn What Makes Up A Quality Metal Panel

Manufacturers offer panels that look the same, but can vary widely in quality and performance. To help you make an educated decision you should understand these specific layers: the paint layer, the anti-rust layer, and the steel core.

MAIN LAYERS OF A METAL PANEL

Use this information to make an informed decision about your next metal purchase. Ask your current metal supplier to explain the layers of protection that are included in their quote.

Gauge Of Metal Roofing With A Pvdf Coating

PVDF is the best paint finish and it is not available in light gauge steel. If you want a PVDF paint finish you will nearly certainly be purchasing 24 gauge steel. You will have a greater selection of colors including bright and vibrant colors, matte finishes, and designer paint finishes.

The single biggest advantage PVDF has when compared to SMP paint is that it will hold the color integrity longer. PVDF paint systems will fade less when compared to an SMP paint system.

If you would like to learn more about SMP and PVDF paint systems then we suggest that you read: Best Paint System For My Metal Roof Panels: SMP v. PVDF

If you decide to use a PVDF paint system then you cannot purchase a light gauge steel. You will have to purchase a minimum of 24 gauge steel. Bright colors should only be purchased in PVDF.

Recommended Reading: Skylights In Metal Roofing

Types Of Metal Roofs And How To Choose

To ensure that the roofing is reliable and durable, does not lose its attractive appearance, you need to know how to choose metal from many different manufacturers. To this end, attention should be paid to the key features of the material.

This roofing is made of galvanized steel with a double-sided protective and decorative polymer coating. The sheet profile imitates natural tiles, which gives the roof a particularly attractive appearance. Metal tile can be mounted on surfaces and constructions of any kind, including those used for laying roofs with a complicated shape. But there is also a limitation of use the slope of the ramp should be greater than 14 ° .

Considering which metal is better, it should be taken into account that this material is successfully used in almost all existing climate zones. Currently, metal coatings are used as roofing :

- private houses

But above all, it is worth assessing the manufacturers warranty. The maximum warranty period is 15 years and applies to metal plates with a polyurethane polymer coating . If the coating is made of polyester, the maximum warranty period for metal roofs shall not exceed 10 years.

When deciding which tile to choose, the following should be taken into account: unscrupulous manufacturers can specify a standard value , while in reality it is 0.45 mm or less. It is recommended to equip it with a micrometer and carry out a selective check before buying.

How to choose a metal roof for the roof?

When Should You Choose The Thinner Panel

The most common type of sheathing is plywood covered by a weather-resistant barrier, with metal panels attached to hold it in place. If the sheathing doesnt have much structural importance, 29-gauge panels work well. Of course, this type of sheathing arrangement is only appropriate for areas that dont often face harsh weather conditions. If you live in an area where there are frequent storms, you should choose a more durable type of metal panel.

In conclusion, gauge really is a simple, yet critical item to consider when selecting metal panels for your new roof or siding. Be sure to consider your environment, temperature ranges, moisture and roof slope before deciding on a proper gauge. And when in doubt, contact ASC Building Products to ensure you select the optimal product for your build!

Want a better understanding of how metal roofing and siding panels are made? Check out this article Roll Forming: What is it?

Also Check: How Much Does It Cost To Shingle A Roof

Some Metal Panels Have A Thin Coat Of Paint But Offer The Same Warranty

A thicker coat of paint fades less, but costs more since it contains more paint. The marketplace offers metal panels with 40-year warranties at a wide range of costs. Ask the manufacturer for their paint thickness on the panels you are considering buying.You may find that the metal you were quoted features a thinner, cheaper coat of paint. A full, thick coat of paint should be between .9 and 1.0 mil thick, including primer.