A Redesigned Yankee Gutter And A Well

Dyami PlotkeIssue 305 – Feb/March 2022A roof is a system.

The PVC roof on my clients midcentury-modern home was decades old and well past its useful life. The patches that seal the fasteners were split and part of a system abandoned by its manufacturer years ago. The homeowners had a local roofer attempt to fix the leaking fastener patches with a fluid-applied waterproofing, but when this didnt stop the leaks, they began to do their own research and contacted Carlisle, a commercial roofing manufacturer. As one of their premier installers, we were put in touch.

I met with the homeowners and reviewed the condition of the roof. The existing PVC was in such bad conditionand the underlying insulation and original roof were so wetthat the existing roof had to be removed, and we replaced it with an EPDM membrane roof. The process involved hundreds of hours and several days of work, but the end result is a roof finally suited for homes modern architecture and ready to stand up to the elements.

Clever Fix For Flawed Gutter

The trickiest part of this roof was the existing Yankee gutter. It was 128 ft. long, starting on the homes north side and curving to the front, over the front entrance. It had 3500 sq. ft. of roof draining into a 2-in.-deep trough framed into the roof, providing a volume of about 10 cu. ft., and it would overflow almost every time it rained. A roof this size really needs a gutter with several times the volume. With both a hanging box and a K-style gutter as aesthetic nonstarters given the homes architecture, we raised the roof edge, filled in the old system, and designed a much larger gutter that wont overflow, even with heavy rain.

Gutter must go.Fill the trough.Make a new gutter.Cover conceals the gutter.

Is Epdm Energy Efficient

There is some debate regarding the energy efficiency, or lack thereof, of EPDM. Actually, the answer to this question depends primarily on location and membrane color.

EPDM is commonly black in color, which is not ideal in warmer climates because dark membranes absorb more of the suns heat. This leads to excessive heat loads on the roof surface which increases cooling costs and accelerates deterioration of the membrane.

In colder climates, black EPDM membranes are the preferred single-ply solution because they retain more of the suns heat, which helps reduce heating costs.

White single-ply membranes such as TPO and PVC offer far greater thermal reflectivity and therefore are far better suited for warmer climates. Roofs with greater reflectivity are more apt to withstand UV exposure and provide increased energy efficiency.

Side Note: Although EPDM is manufactured in white, its not nearly as common as other default white single-ply membranes such as TPO and PVC. This is likely due to the lower material cost and ever-increasing market share of TPO and PVC.

Ultimately, determining the suitability of an EPDM roofing system as it relates to energy efficiency depends on the number of cooling and heating days in a given location.

Read Also: How Much Do New Shingles Cost

Cost To Install A Rubber Roof

Many homeowners make the mistake of assuming that flat roof installation and work is less expensive than pitched roof work. After all, flat roofs are much less complicated to access, and its a lot easier to move around on a flat surface than on a sloped one. We have some tips on hiring a flat roofing contractor for your convenience.

However, many roofers will attest to the fact that working on flat roofs is more physically taxing than working on steep ones. Flat roof work may not call for a harness and brace system, but it does involve more stooping, bending, and lifting than pitched roof work.

Additionally, flat roofs require more elaborate installation processes that involve the handling of adhesives and the use of sophisticated application techniques.

For these reasons, installation and labor costs for a flat roof can be as high asor higher thanthose of a pitched roof.

Rubber roofing materials are typically more expensive than traditional composite shingles, as well. However, a rubber roof will last longer and offer more benefits than asphalt shingles or asphalt roll roofing.

Surface Preparation For Epdm Roof

Just like any other roof product, it is very important that the surface you are working with is clean and dry. If there are any cracks in the concrete or if there are peeling shingles on your roof, these will need to be fixed before applying an EPDM rubber roofing membrane. Once the roof surface is clean and dry, you should inspect it for any damage that might need to be repaired. If there are any holes or valleys in the EPDM rubber roofing membrane, these can be repaired with an adhesive repair kit.

Read Also: Cost To Reseal Rv Roof

Before You Start To Install Epdm Roofing Make Sure That Your Roof Is Clean And Dry

Also that the temperature is likely to remain above 5 degrees C for the next 24 hrs. . In addition, check that all nails and screws have been driven below the surface of the roof deck, for obvious reasons.

Roofing membrane laid out on clean and dry roof deck

Side note: I completed the featured job in the middle of December in the UK. It was raining as I finished nailing on the last roofing boards. It then froze that night. I spent the next couple of days getting the roof to dry out in the weak, mid-winter sun. I was lucky that I then hit a dry spell. The weather warmed up enough for me to dry out the roof and to bond the roof with the expectation that the temperature would remain above 7 degrees for that night.

Laying the membrane out flat on the roof is a double check that you calculated the size correctly. I found it interesting to handle this material and see how tough and flexible it really is.

Membrane on roof prior to bonding. The membrane overhangs the roof on all edges.

Laying And Relaxing The Membrane

Before fixing the membrane in place, it needs time to relax as EPDM membranes often arrive tightly packed. This allows it to expand and contract back to its neutral state. Remember to unfold it carefully to ensure it doesnt get dirty and allow it to relax in position for around 20 to 30 minutes. This is a crucial step not factoring in relaxing time could leave you with a wrinkled surface that ponds water in the future.

Recommended Reading: How To Add A Gable Overhang

Different Types Of Rubber Roofing

A rubber roof is, you guessed it, a roof made of rubber materials. But its much more complex than that. There are actually many types of rubber roofs, each with its own benefits, disadvantages, lifespans, and installation methods. Today well walk you through each and help you determine which is best before tackling your DIY install.

Lifespan Of Rubber Roofing

Once you have an EPDM roof professionally installed, its lifespan will vary based on a few factors, the two most important being the thickness of material and weather exposure over time. Generally, if the EPDM roof you have installed has a thickness of 45 mils, it will last for a period of about 12 years. With a thickness of 65 mils, you can expect the roof to last 12 to 17 years. An EPDM roof with a thickness of 90 mils can last 25+ years.

Standing water is also a concern for EPDM roofs if water accumulates and stays on the roof for more than 48 hours, this can result in damage. However, 95 percent of EPDM roof failures are actually attributed to poor installation. An EPDM roof with a thickness of 90 mils that has been installed by a competent and professional rubber roof installer can have a lifespan of more than 30 years.

Also Check: How Much Does A Roof Cost In California

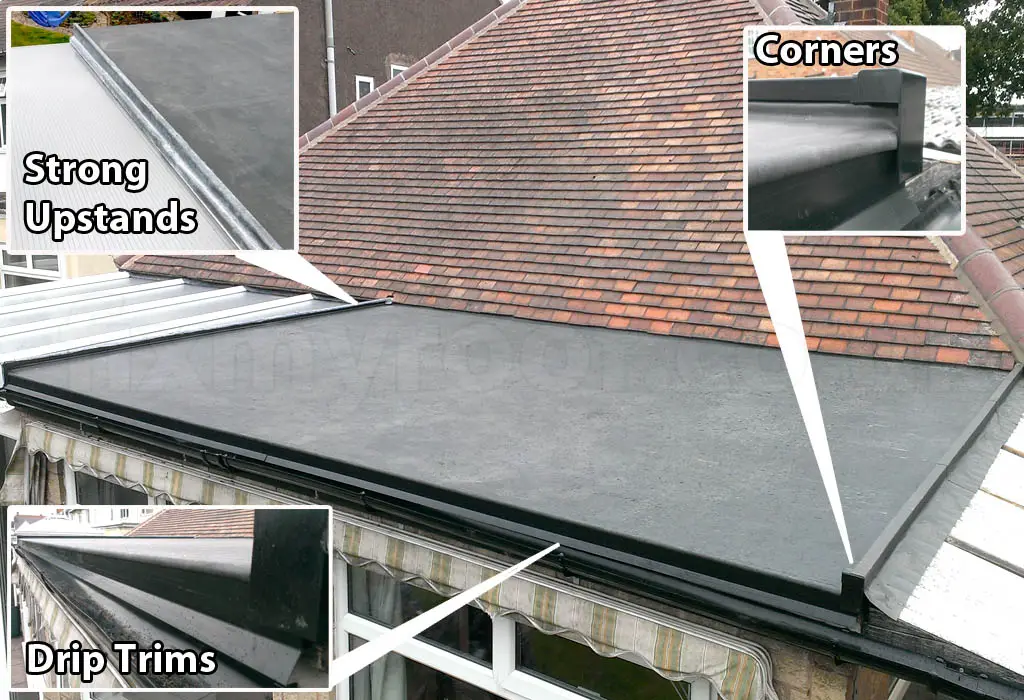

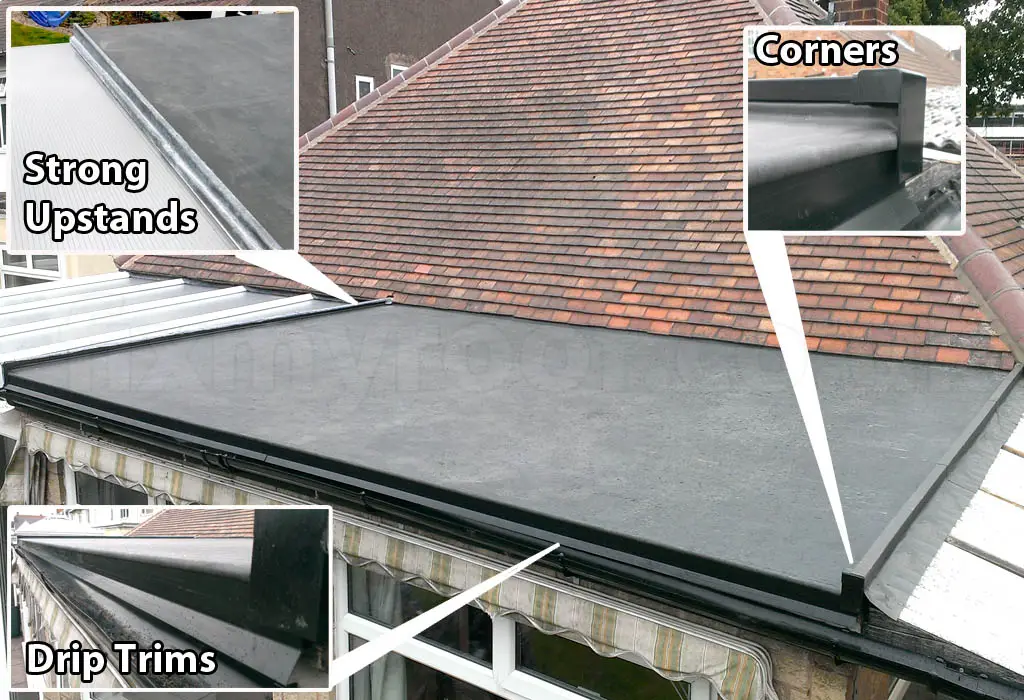

Apply Contact Adhesive To Roof Perimeter

Apply a THIN coat of Contact Adhesive to the roof deck perimeter and any vertical upstands. Also apply the Contact Adhesive to the back of the rubber membrane.

Contact Adhesive can also be used to bond the rubber membrane to most porous and non-porous surfaces so can be used in place of water based deck adhesive if necessary

What You Will Need

DIY EPDM Repair Kit: This is likely to be the easiest option, as these kits have everything youll need except for a caulk gun or scrub brush, and they have an appropriate amount of each material, so you dont end up with a lot of something left over.

One or two holes: See this repair kit .

- Cleaning Brush, Soft-Bristled

- Cleaning Rags

- Seam Roller, Handheld

Also Check: Solar Shingles Cost Per Square Foot

How Long Should A Rubber Roof Last

If you are a contractor or are familiar with the roofing game, you may have heard of EPDM. This is Ethylene Propylene Diene Monomer which is more commonly known as rubber roofing. Most contractors will recommend that owners of a commercial property invest in these rubber roofs.

Rubber membrane roofs have advanced durability, life expectancy and cost per square foot that makes it one of the best replacement options for any kind of damaged roofing material. And while it certainly has disadvantages of its own, there are more than enough reasons that EPDM roofs are one of the most common options for commercial properties.

Epdm Roof Installation: Step By Step

First comes the step of having the EPDM roof materials delivered to the job site. Your local roofing contractor will drop off all the required roofing materials at the job site before installation. For most commercial property owners, it is extremely important to keep their business operating during a commercial flat roof installation. Infinite Roofing and Construction follows an extensive safety plan and have years of experience in performing a commercial roofing installation with minimum impact to the operations of the business. We know the best way of preventing accidents is to identify all possible sources that may cause them on the job site before any work begins. Any potential hazards will be highlighted and eliminated as an issue so you can rest assured that your business is in safe hands.

Don’t Miss: How Much Shingle Roof Cost

Mechanically Attached Epdm Systems

Mechanically attached EPDM is attached using seam plates and roof fasteners dispersed across the surface area of the roof. These fasteners are screwed into the EPDM membrane in order to secure it to the roof. Fasteners are penetrations in the roof membrane which can sometimes be a cause of water issues and leaks if they are left exposed. However, many mechanically fastened EPDM roofing systems account for this and include a way to cover these potential penetration points.

Should I Consider Rubber Roofing For My Home

If you have a low-pitched home, consider rubber roof installation. This choice is also ideal if some part of your property accumulates water or ice dams during cold weather. Since determining your homes pitch may be tricky, consult residential roofing experts before choosing this material.

With their help, you can determine if installing rubber roofing will protect your home from water damage. These experts also guide you in choosing a suitable underlayment.

Read Also: How Often Does The Roof Need To Be Replaced

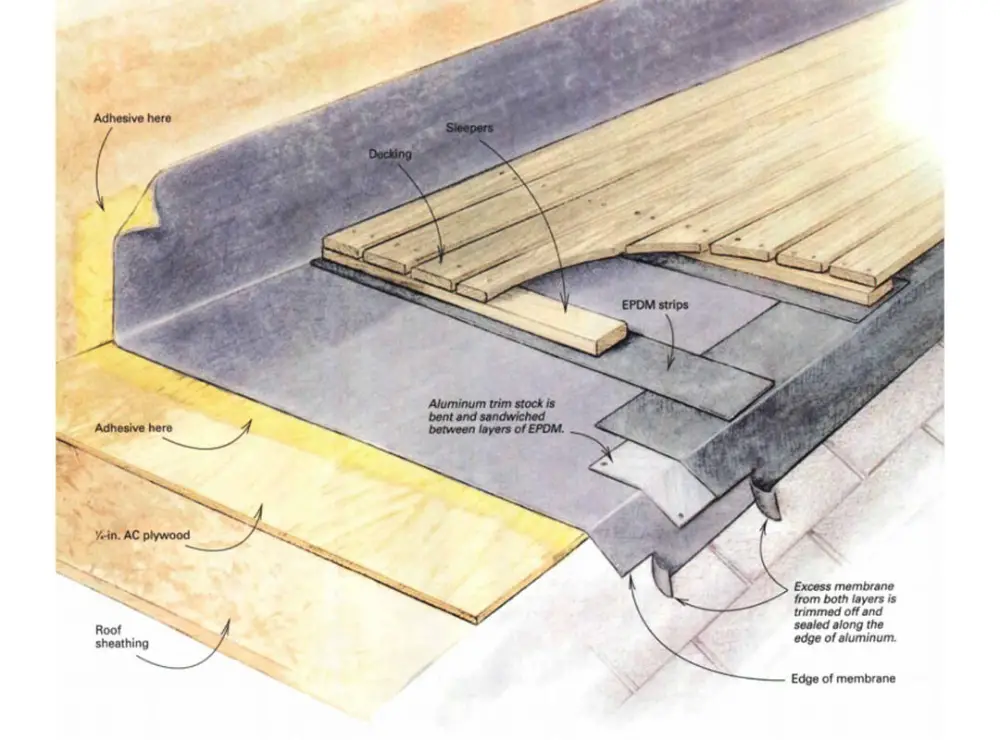

Prepare The Roof Deck

The roof deck should be thoroughly clean from any oil or grime, and you should sand any sharp edges of the plywood or OSB board. Even a small amount of moisture can lead to problems with the adhesive, so its essential that everything is dry before you begin your EPDM installation.

If youre installing your EPDM over an existing roof, you should cover it with clean, sanded plywood or OSB board to provide a barrier to protect the membrane. If youre applying the EPDM directly to roof decking, you should consider adding a layer of insulation to prevent problems with water vapor. Install it according to the manufacturers guidelines. For better insulation, you can use chemical adhesive.

How To Install Rubber Roof Yourself

Whether it is a flat roof or pitched roof, a rubber roof is a great choice to ensure against leaks from rainwater or snow. When water sits on the roof, it is easy to find ways to come into the roof structure. A rubber roof will prevent this leak by making the water goes down the roof.

Read Also: Roofing Costs In California

You May Like: Roof Overhang Extension

All About Epdm Roofing

EPDM basically is a kind of rubber material. This material is used in waterproofing the roofs. The use of this kind of roofing makes the roof water repellant and resistant. We must understand how to install rubber roofing on a flat roof. While installing the EPDM roofing, we must be very careful. We should make sure that there are no wrinkles, bubbles, stretching, ponding, dips and the presence of visible bolts. If these are present at your roof, this must be looking very ugly. Not only ugly but the presence of these factors also hampers the efficiency of the roof.

The most effective system or the most effective way to install EPDM roofing is to glue it down on the flat roof. The most important instruction here would be that the glue used for the roofing purpose should be of very good quality and also contaminant free. Getting this roof installed in the right way is the most important factor. Before getting this roof installed the contractor must check with the quality of the EPDM rubber roof. You should only move ahead if the quality of the EPDM roof is nice.

Surface Cleaning & Preparation

To achieve optimum results for your EPDM roof, you must first ensure that the roof space is correctly prepared. Brush down the roof surface using a soft brush to remove all dirt, grease, dust, debris and contaminants. Also remove any existing coverings such as asphalt layers. You need to work through this step thoroughly as any leftover waste will have an impact on the quality and ease of your EPDM application.

The roof will also need to be completely dry as the product will not adhere to wet surfaces. Any moisture or water trapped beneath is likely to vaporise which will significantly hinder the performance of your EPDM roofing system.

Carry out a thorough inspection to locate any cracks or gaps in the roof. The EPDM rubber will not adhere to any gaps larger than a quarter of an inch in size, so fill these in using wood strips.

Later on in the installation process, wall trim flashing will be installed. To prepare for this, chase out the brick mortar joint using an angle grinder or mortar chisel.

Recommended Reading: Shed Eave Overhang

Durability Of Epdm Roofing

EPDM roofing installation results in a beautiful rubber roof that maintains superior durability. Due to its ability to expand and contract, EDPM is able to resist cracking in both extreme hot and cold temperatures. When it is extremely hot outside, EPDM roofing can naturally lower the temperature of your roofs surface by as much as 80 degrees. To achieve optimal temperature regulation, it is recommended to paint a black EPDM roof with a white water-based acrylic paint.

The EPDM roofing material is also known to be extremely durable in harsh weather conditions like snow, ice, hail, and wind. When exposed to standing water for an extended period of time, though, damage can result this is why we highly recommend to ensure your roof has proper drainage before installing an EPDM roof. A roof squeegee can be used to minimize standing water on roofs that dont have a slope or pitch. And to speed up water evaporation, it is suggested to keep nearby tree limbs trimmed to allow the suns UV rays to dry the roof this will enhance and extend an EPDMs roof durability.

How Do You Fit A Rubber Roof

Installing an EPDM flat roof rubber membrane is far easier than a traditional roof. When done correctly, a roof membrane can be expected to last in excess of 50 years. Thats why its the number one choice for homeowners.

We have broken down the installation of the Flexi Proof rubber roofing membrane into 5 easy steps.

Don’t Miss: How Much Is A Shingle Roof Per Square Foot

How To Clean Epdm Roofing

Cleaning EPDM rubber roofing helps to maintain its appearance and qualities, as well as enabling you to conduct roof inspections. Any loose dirt or debris can be easily swept or hosed off, leaving you with a clear area to apply a rubber roof cleaner. Working in small areas, apply the solution to the roof in circular motions with a soft brush or mop. Rinse the area well to ensure any dirty residue is removed from the membrane.

How To Install Epdm Roofing

Single ply roofing can be installed using mechanical fasteners, a ballasted system, or fully adhered with chemical adhesive. Fully adhered installations offer the best leak resistance and the longest life expectancy, but they are also more difficult. They require experience and skill in order to avoid common mistakes that can lead to roof failure.

Don’t Miss: Cost To Reroof A House In California

Comparing Epdm Roofing To Alternative Materials

For roofs with little to no pitch, there are many roofing material options available. Which one is right for you depends on many factors, including your budget, needs, climate, design, and many other things.Here is a quick breakdown and comparison of some of the most popular EPDM roofing alternatives:

| Roofing Type |

|---|

Done With Care A Flat Roof Can Provide 20 Years Of Leak

Synopsis: Flat roofs are difficult to install properly, and as a result, many dont last for anything close to the life span theyre capable of achieving. In this article, roofing specialist Dyami Plotke describes his process for getting the details right so that a low-slope EPDM roof can last for 20 years or longer of leak-free service. Plotke begins by making sure hes working on a stable substrate, such as high-density gypsum board. He also lines up an assortment of appropriate sealantsurethane, water-block mastic, and lap caulkand uses them in the correct locations. Seams between sheets of EPDM should be connected with a special 6-in.-wide seam tape avoid the urge to use splice cement, which is seldom applied correctly and often fails prematurely. Pieces of edge metal, such as gravel stop and drip edge, are sealed in place. Also, sidewalls are a critical joint that requires counterflashing. If the roof has any pipe penetrations, they can be managed with boots, preformed pipe seals made from molded EPDM.

Editors note: If you want to learn how to build a deck on top of a flat roof, read the article

Also Check: How To Repair A Trailer Roof