Whats The Most Expensive Type Of Roofing Material For A Replacement

President at Bill Ragan Roofing Company

When choosing a roofing material for their replacement, a lot of homeowners look for affordability. This is understandable because a roof is a big investment.

But sometimes, whether its out of curiosity or genuine interest, some homeowners ask what the most expensive type of roofing material is. Because choosing the right roofing material is such a big decision, Ill answer that question and more.

For over 30 years, Bill Ragan Roofing has helped homeowners like you choose the right roofing material for their replacement. Now well help you determine if the most expensive roofing material fits your budget.

To start this article, well get right into what the most expensive type of roofing material is and how it costs. After that, youll learn the cost of 4 more popular residential roofing materials, so you can find the one that fits your budget.

And at the very end, we provide a guide with even more information to help you really determine which roofing material is right for you.

Dont Miss: Proper Screw Placement Metal Roofing

Other Factors To Consider When Buying Metal Roofing Screws

As youd expect, size is the first of many other factors you must consider when shopping for metal roof screws. Other factors to prioritize are

- Screw head types: Popular screw head types are hex washer head, flat head, pan head, oval head, round washer head, pancake head, and wafer head screws.

- Threads per inch : The number of threads per inch on the screw determines the coarseness or fineness of the screw. Generally, coarser screws are stronger and more suited for thicker metal panels. The opposite is true for fine screws.

- Specialty screws: Some screws are designed for special purposes. For instance, we use lap screws to attach the panel side lap on exposed fastener panels. Meanwhile, self-driving screws, better known as TEK screws, eliminate the need for pre-drilling.

- Drill point style: Besides self-drilling screws, self-piecing and self-tapping screws are other popular drill point styles. A self-tapping screw taps threads into the material but doesnt drill through metal. Meanwhile, a self-piercing screw pierces light-gauge metal and taps threads into the material.

Less Qualified Contractors Have Experience Installing Standing Seam Roofing

Finding a contractor who is qualified, skilled, and experienced in metal roof installation is vitally important, especially because standing seam systems require careful craftsmanship. Since standing seam installations may be considered too complicated or tedious, there are far fewer contractors to choose from who have a proven track record and the relevant experience.

Recommended Reading: Replacing Roof Trusses

You May Like: How To Change A Flat Roof

Dont Assume That All Sides Measure Equally

If you have measured one side of the roof and the panels you need to cover it you might be tempted to just double your measurements to cover the other side of the roof too. However, the two sides of the roof can be of different measures, so it is important to measure all sides and repeat the calculations. All you will need to do is add the number of panels needed for each side.

More Options For Standing Seam Systems

Striations or Stiffening Ribs

Striations, also called stiffening ribs or rib rollers, are the patterns rollformed into a metal roofing panel between the seams. These can be used to assist with the installation of a metal roof, to help reduce the visibility of oil canning, or just for curb appeal. In fact, we recommend using striations in standing seam panels, some available options include:

- Flat No indents between the seams

- Striated Small consistent indentation lines in the panel

- Ribbed Shapes or indentations between the seams

- Pencil Circular panel indents

- V-Ribs V shaped panel indents

- Bead Longer, rectangular panel indents

Thicknesses

The metal coil that is rollformed into panels comes in many different thicknesses however, standing seam panels are typically somewhere between 22 and 26 gauge, with the most common Galvalume® thickness being 24 gauge and aluminum between .032 and .040 inches.

You May Like: How Far Apart Should Screws Be On Metal Roof

Recommended Reading: Can You Pressure Wash Your Roof

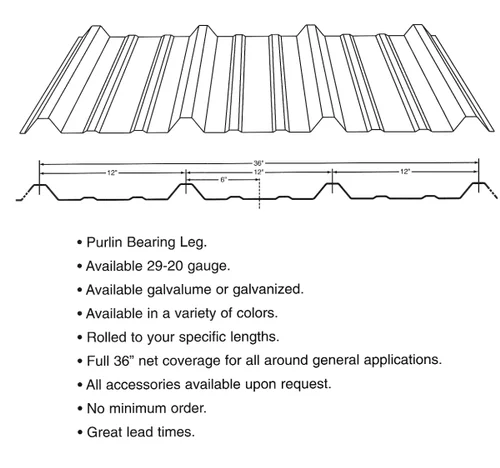

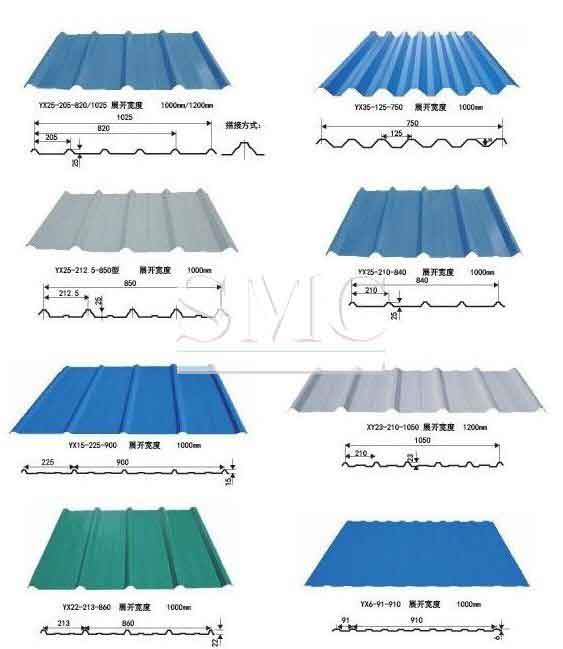

How Wide Are Metal Wall Panels

Metal wall panels come in a variety of sizes, but typically range from 24 to 48 wide. The exact width of the panel can depend on the type of metal panel and manufacturer, so it is important to consult with a professional or check the manufacturers specifications before purchasing or installing.

Generally, metal wall panels come pre-painted and can be installed without hassle. They are a popular choice for modern, industrial, or contemporary looks. Additionally, metal wall panels can be used to hide some imperfections in a wall, such as chips or cracks.

They are also known for their excellent fire and weather resistance. Metal wall panels come in a variety of finishes, from smooth to textured, allowing for a unique look depending on the customers preference.

How Wide Is A Standing Seam Roof

The width of a standing seam roof varies depending on the style and type of roofing panel you choose, as well as the height of the roof. Generally speaking, standing seam roofing is usually between 12 18 wide, but this can be customized to fit the buildings particular roofing needs.

In addition to the standard widths, custom widths are available from some manufacturers as well. The two most popular standing seam roof styles are flatlock and vertical. Flatlock panels are typically 16-18 wide and are more economical, while vertical panels can range from 12 18 wide and provide a much more modern look.

The width of the standing seam roof panel also depends on the pitch of the roof, so it is important to work with a professional installer to ensure your roof is properly sized and installed.

Read Also: What Is The Going Rate For Roofing Per Square

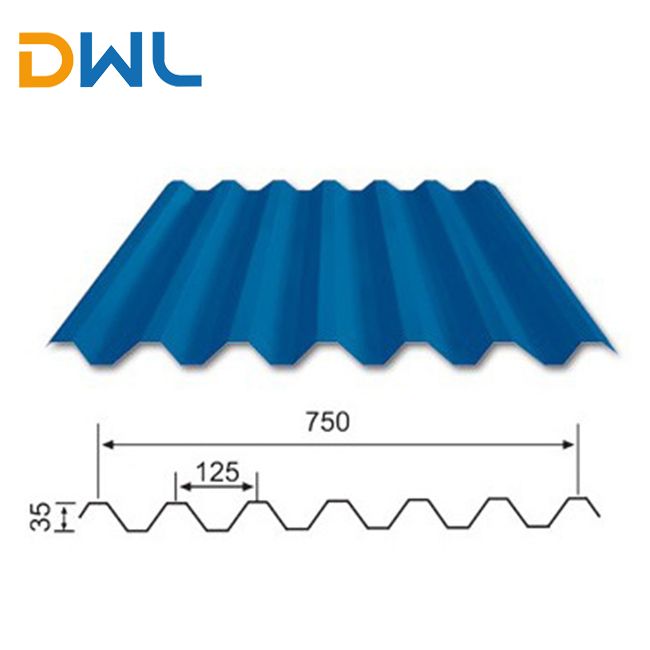

What Is A Corrugated Metal Roof

Corrugated metal roofing is one of many types of metal roofs. It features sheets that have undergone roll forming to create round and wavy panels that are more sturdy and durable. These panels are attached to the roof deck using exposed fasteners.

This type of metal roofing is preferred for its lightweight, durability, energy efficiency, and the fact that it is easy to install. It is an excellent alternative to asphalt shingles or clay tile roofs. Although it is a popular choice for roofing, people also use it for siding projects.

The term corrugated metal roofing is often mistakenly used to refer to all metal panels with roll-formed grooves and ridges. That generalization lumps corrugated metal panels together with their cousinsribbed metal panels.

What Color Is Roof Thickness

There are three thickness of yero for sale we currently have. These are 0.4, 0.5 and 0.6 millimeters. We usually recommend at least a 0.4mm for residential projects. For those who are looking into cheaper alternatives, a 0.35 millimeters thickness exist in the market.Dhul-H. 20, 1439 AH

What is thickness of GI sheet?

Galvanized Sheets

| 0.0306 inches0.77724 mm |

Which sheet is best for roofing?

Bitumen Roofing Sheets Bitumen roof sheets are one of the best priced roofing solutions on the market and are Roofinglines most affordable roofing sheets. Waterproof, low maintenance, lightweight and straightforward to install, bitumen sheets are a long-lasting option that can be modified to suit most roofing needs.Shaw. 13, 1439 AH

Don’t Miss: How Much Overlap On Metal Roofing

Benefits Of Metal Roofing Screws

Originally, roofers used nails for metal roof panels. But later, the fasteners evolved into nails with washers for leak protection. Then manufacturers began making threaded nails with sealing washers for greater holding power and weather tightness.

The evolution hasnt stopped. Today, metal roofing screws are preferred because they are easier to install and offer greater holding power. Moreover, modern-day roofing screws are beautiful and corrosion-resistant.

Above all, screws are more resistant to wind pullout but easy to remove with drills and other tools. Also, unlike nails, you can lift screws off a metal roof without damaging the panels. Therefore, previously screwed metal panels are more reusable than nailed panels.

What Size Are Corrugated Roofing Sheets

Corrugated roofing sheets come in a variety of sizes to fit the needs of homeowners and businesses. Some popular sizes include 8, 10, 12 and 16 foot sheets. The most common type used for residential buildings is the 8 foot sheets.

These measure 8 feet long by 26 inches in width. Most common colors available for corrugated roofing sheets are galvanized white, red, terra cotta, green, and metallic colors such as bronze and copper.

Some companies may offer custom colors but that will depend on the manufacturer. Depending on the manufacturer, thicknesses also differ. Typical corrugated roofing sheets range from 24 gauge to 29 gauge.

The 24 gauge is thicker and more suitable for harsh weather climates such as hurricane or high winds. The thinner 29 gauge is usually used in lighter weather climates such as moderate wind and rain areas.

Ultimately, the size of sheet you choose should depend on your local weather climate and the design of your building or structure.

Read Also: How To Keep Snow From Sliding Off Metal Roof

Industry Standards & Testing For Paint Specifications

Metal roofing paint systems come with standards and testing that ensure the success of a paint system. We wont dive too deep into these standards, but just know that there are various. However, adhering to them is the responsibility of the paint company, such as Sherwin-Williams, to test before the paint ever reaches a metal coil.

Metal roofing paint systems endure stringent testing, like the natural outdoor exposure test in the photo, to ensure the paint system stands up to chalking, fading, chipping, peeling, and other overall failures.

For example, a standard two-coat polyvinylidene fluoride typically adheres to the following standards set forth by ASTM:

- Accelerated weathering ASTM G23

- Acid resistance ASTM D Procedure 72

- Abrasion resistance ASTM D968

- Tunnel test ASTM E84

In other words, the paint goes through a lot of testing to make sure it doesnt crack, chalk, fade, peel, or succumb to any other damage prematurely. These tests are why many paint manufacturers guarantee their PVDF products with lengthy metal roofing and wall system paint warranties. If you have questions about the testing that goes into a panels given paint system, we recommend contacting the paint manufacturer.

Wider Metal Panel Widths

Standing seam panels typically come in ranges from 12 to 24 wide. Wider panels are typically more cost effective for a couple of reasons. First, they generally cost less to purchase from the manufacturer. The lower cost comes in part from personnel at the manufacturing facility physically producing less panels to cover the same square footage. There are also some freight advantages with wider width panels as there is less crating and packaging involved to cover the same roof plane.

But the bigger benefit comes in the form of labor and accessory savings. As you might imagine, a contractor can install 1-24 wide panel much more quickly than he can install 2-12 wide panels to cover the same space on the roof. In this example, in addition to handling more panels, the installer would also have the additional cost to purchase and install twice as many clips to attach the narrower panel to the substrate than he would the wider panel option. Labor and materials arent necessarily cut in half for the wider panel but the savings are significant.

Also Check: Where To Buy Cheap Shingles For Roof

Gauge Corrugated Metal Roofing

If you want an inexpensive metal roofing panel then standing seam is not the best option for you. The best value will be a 26 gauge exposed fastener panel in a SMP paint finish. Keep in mind though that an exposed fastener panel means that you will have thousands of screws that will penetrate the panel. Each screw is a potential leak point at a later date.

A corrugated panel will cost $1.00-$1.25 per square foot in a 26 gauge SMP paint finish.

If you would like to learn more about exposed fastener and concealed fastener panels, we suggest reading or watching: Exposed Fastener Metal Panels v. Standing Seam Systems For Metal Roofs

How Wide Is A Piece Of Metal Roofing

Metal roofing comes in 24 and 36-inch wide measurements. However, each of these widths also provides for 2-inch overlap on both sides. You can purchase metal roofing material in any length you need and have it cut to the appropriate length before you install it.

Similarly, you may ask, what is the standard width of metal roofing?

The two most common widths are 26 and 36 inches. Other standard widths include 24 and 39 inches. When calculating coverage using the width and length of corrugated roofing, keep in mind that each piece will need to overlap by several inches.

what is the width of corrugated iron? 850mm

Furthermore, how do you measure for metal roofing?

Divide the length of your roof by the width of the metal. In our example we will use 24-inch standing seam roofing, so we will divide 360 inches by 24, which equals 15. This is the number of metal panels needed for one side of the roof.

How wide is colorbond roofing?

762mm is the cover width which allows for 1.5 rib overlap. The actual single sheet width of the corrugated sheet is 850mm wide.

Read Also: How To Get Tesla Solar Roof

Corrugated Metal Roofing: The Cheapest Metal Roof Option

Before 1829, metal was rarely used as a roofing material since it would often warp or dent when exposed to the elements. All this changed with the invention of corrugated iron. Today, it is one of the most common metal roofing options available.

Corrugated metal roofing is relatively cheaper and easier to install when compared to other roofing options such as standing seam. In this article, we tell you all about this type of metal roofing. We also answer some of the most frequently asked questions.

How Far Apart Should The Rafters Be

The standard roof rafter spacing is 16 inches or 24 inches on-center. However, you can also space your roof rafters 12 inches or 19.2 inches on-center.

These standard rafter spacing measurements apply to standard roofing projects. For instance, Douglas fir is the standard wood rafter material in the US, UK, Australia, and Canada. Meanwhile, the standard rafter size is 2×4 for areas with low roof loads and 2×6 for regions with heavy roof loads.

The exact space between two rafters matters little, provided you use the right rafter sizes and spacing. Thats because all rafters are two inches wide when installed.

Also Check: How Are Shingles Put On A Roof

Astm E2140 Standard Test Method For Water Penetration Of Metal Roof Panel Systems By Static Water Pressure Head

ASTM E2140 is a water penetration test evaluating the resistance of roof panels, sideseams, endlaps, and roof plane penetrations to water submersion.

According to the standards scope:

This laboratory test method covers the determination of the resistance to water penetration of exterior metal roof panel system sideseams, endlaps, and roof plane penetrations when a specified static water pressure head is applied to the outside face of the roof panel.

During this test, the roof panel system is completely submerged under water to test its ability as a water barrier. This test method is intended to evaluate water-barrier roof system joints and details. These systems are also referred to as hydrostatic roof systems .

Other Factors Affecting Metal Roof Durability

Metal Type

The type of metal used varies in price. Copper and zinc cost more than aluminum or steel. The life expectancy and durability of each type of metal can affect the price. Different types of metals also can use different measuring standards, which means that two different metals that are of the same gauge may not actually be the same actual thickness. Because thicker panels are more expensive, a metal that has a thicker measurement for the same gauge than another type of metal may cost more.

Steel Hardness

If you opt to use steel as your metal of choice, youll find that harder steels are more durable. Steel is measured using grades or units of tensile toughness. For example, a full hard grade 80 steel, or 80,000 psi minimum tensile strength is stronger than a grade 50 or 50,000 psi tensile strength.

This is a major factor in determining how tough a roof is. If a roof has a higher gauge but higher-grade steel then it can be more durable than lower gauge roofs.

Fasteners

Fasteners secure the roof membrane to the structural roof deck. This improves the durability of the roof overall. These can create a stronger roof despite a higher gauge if placed at specific intervals.

Potential Damage

Location

WHICH GAUGE METAL ROOF IS BEST FOR YOU?

Recommended Reading: How Many Squares Do I Need For My Roof

Striations Stiffening Ribs Or Rib Rollers

Striations are the patterns rollformed into a metal roofing panel between the seams. These can be used to assist with installing a metal roof, to help reduce the visibility of oil canning, or just for curb appeal. In fact, we recommend using striations in standing seam panels some available options include:

- Flat No indents between the seams

- Striated Small, consistent indentation lines in the panel

- Ribbed Shapes or indentations between the seams

- Pencil Circular panel indents

- V-Ribs V shaped panel indents

- Bead Longer, rectangular panel indents

How Long Are Metal Roof Panels

Roofing systems composed of steel and metal include thin, lightweight flat roofs and pitched roofs. Metal roofing is available in 24 inches width and 36 inches width.

However, because there is a 2-inch overlap on both sides for each of these widths, its the ideal complement to the existing range. You may buy metal roofing in whatever length you want and have it cut to the right size before installing the metal roof panel.

In this regard, what size are metal rooftop panels? The steel panels are available in 18, 20, 22, and 24 gauge widths with widths of 27 to 46 inches. The panel in 48 inches can reach up to 12, 10, and 8 feet long, while the panel that is 27 inch in width can be up to 20 feet long.

Second, how can you quantify metal roofing panels in terms of length and width?

The length of your roof is divided by the width of the metal. In our scenario, well utilize 24-inch standing seam roofing, so divide 360 by 24 to get 15. The number of metal panels required for one side of the roof is 15 in this case then.

Don’t Miss: What To Use To Clean Roof Shingles