Corrugated Metal Roofing Is Resistant To Fires And Rot

Metal does not rot or support any microorganisms such as mold or mildew unlike asphalt shingles. It also isnt susceptible to termite or rodent infestation. Damage caused by all these factors are both inconvenient and expensive. Having a metal roof eliminates any worries of having to deal with those issues that are both expensive to fix and could cause health issues.

Another big advantage to metal is that its one of the few fire-resistant roofing materials. It has the best fire rating available, making it ideal for areas that are prone to wildfires. A fire-resistant roof protects your home and your family from the danger of a fire.

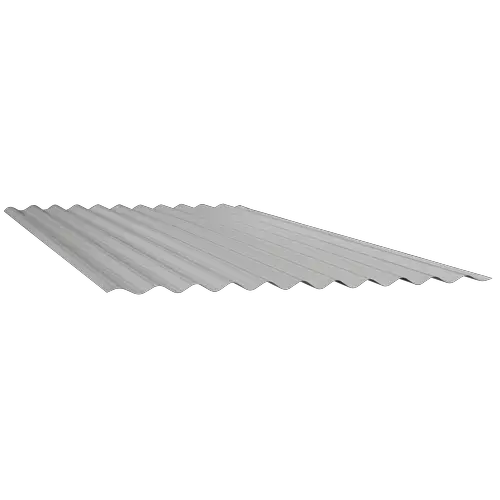

Clean Cut Corrugated Metal Ceiling Design

The clean-cut style of corrugated metal ceilings is great for those who really want the idea of corrugated metal front and center. Its typically implemented with basic, silver corrugated metal and paired with complementary, neutral-colored framing. This style works perfectly in a modern aesthetic as well as a minimalist design theme.

How Many Hours Of Daily Sunlight Does Your State Receive

The sunlight available to produce electricity varies greatly throughout the United States. Southwest states like California and Arizona get the most sunshine, while northeast states like New York and Massachusetts get the least.

However, you should not discard solar power just because you live in a state that isnt sunny. For example, New York only gets moderate sunshine, but it has very high electricity prices. Solar panels are worth it in this case, since they achieve high savings even with reduced production. Saving 750 kWh when you are charged 25 cents/kWh is better than saving 1,000 kWh at 12 cents.

After estimating how many panels are needed in your home, you can make better purchasing decisions. Keep in mind that you dont have to pay the full system cost upfront. Many banks finance for solar panels, and you can pay off the loan with the electricity savings achieved. Leasing solar panels is also a viable option, where you pay a monthly price instead of purchasing the system. Your local solar installer may offer several purchasing options, adapting to your needs.

We hope you liked this article. Please rate it or leave us a comment.

Read Also: Shingling A Shed

You May Like: How Much Solar Can I Fit On My Roof

Corrugated Metal Roofs Vs Metal Shingles

The main difference between corrugated metal roofing and metal shingles is the size of the metal. When installing a corrugated metal roof, the entire sheet of paneled metals is screwed on the roof. For metal shingles or tiles, individual pieces are attached to the roof.

Corrugated Metal Roof

- Lasts 40 to 80 years

- More expensive than corrugated metal roofing

- Hard to repair if damaged

- Shingles subject to expansion and contraction

Corrugated metal roofs are sturdy and strong and used to cover longer roofs. They are mainly used for agricultural, industrial, and commercial purposes, but can also be used for some types of residential home roofing. On the other hand, metal shingles and tiles are specifically designed for residential roofs and come in several styles and designs.

Corrugated Metal Roofing: Everything You Need To Know Before Buying

Source: Mullets Aluminum

Metal is the second most popular type of residential roofing option in the United States, according to 2019 data.

Considering the benefits of metal roofing, including longevity, return on investment, and minimal maintenance, this should come as no surprise.

Corrugated panels, one such type of metal roofing, sweeten the deal with superior durability and affordability.

Although corrugated metal roofing is certainly worth a look for these reasons, we recommend considering the costs, potential drawbacks, as well as alternatives before making any buying decisions.

Read on to get a well-rounded take and our recommendations on corrugated metal roofing.

Also Check: How To Walk On Tile Roof

Corrugated Metal Roofing Is Energy

Metal is one of the most energy-efficient roofing materials. Besides being made of 100% recyclable material, it also helps homeowners reduce monthly energy bills by reflecting solar radiation back into the atmosphere.

A metal roof can result in homeowners having a general energy savings of 7% up to 15%. One study funded by the U.S. Department of Energy showed an annual savings of 25% on cooling costs.

What Are Clips Benefits

But clips do much more than attach panels and make the roof look nice. Standing seam metal roof clips are specifically designed to interact with their corresponding roof panels to accommodate design loads, allow movement caused by thermal changes and minimize deflection due to friction, says Duane Sailors, vice president of engineering and sales, BPD, a LSI Group company, Logansport, Ind. Clips are designed to match the profile of the intended panel to allow for a nested installation. This nesting allows necessary movement as well as sealed seams and aesthetic appearance. It is important to understand the necessary movement is due to thermal influence: both interior and exterior.Standing seam metal panel clips are designed to enable dimensional change of the panel without fatigue of its fastening, allowing for the thermal cycling process, says Cindy DeBellis, sales director, SFS Group USA Inc., Wyomissing, Pa. They provide durability and protection from the elements as well as improved aesthetics as they are a concealed fastening system as opposed to through-fastened systems.

Don’t Miss: How To Repair A Mobile Home Roof

Types Of Metal Roofing

Before we get into the steps on how to install metal roofing its important to understand what types of metal roofs exist. While metal roofing can be made from a variety of metals, tin, zinc, steel, aluminum and copper are the most widely used and most commonly available options. Each metal has its own advantages and disadvantages, as well as cost considerations. Steel, for example, is the least expensive option while copper is the most expensive.

In addition to material choices, metal roofing is also available in three design styles: through-fastened panels , modular panels and standing-seam panels.

- Through-fastened corrugated metal panels are the most common and readily available type of metal roof. They can be installed over roof sheathing or purlins.

- Modular panels, which mimic other roofing materials like asphalt shingle and tile, are also available in a wide range of colors and styles. They, too, can be installed over solid sheathing or wood battens.

- Standing-seam panels install over solid or skip sheathing and have the most complex installation process, so are typically best left to professional roofing installers.

What Is The Average Cost To Replace A Tile Roof

In general, it costs between $80 and $120 per square metre to have a tiled roof installed. $80m2 is a fairly simple single storey roof. It could cost more than $120m2 for a complex roof with a steep pitch. As a rule, installers charge around $2 to $5 more for every 5 degrees the pitch increases over 35 degrees.

You May Like: How Do You Insulate A Flat Roof

Also Check: How To Repair Epdm Roofing

Should You Buy Corrugated Metal Roofing

Corrugated panels yield a compelling combination of sustainability, durability, and resistance to the elements, among other worthwhile benefits.

Price varies widely depending on the base metal, with galvanized steel and aluminum firmly on the sensible side while zinc and copper both post high barriers to entry. At a minimum, a properly installed and maintained corrugated metal roof should last 30 years.

Corrugated roofing is not perfect, however. We docked points for the exposed fasteners, maintenance needs, and questionable style.

Some other metal roofing systems, namely standing seam, are longer lasting and, in our opinion, more attractive. If you’re eager and willing to splurge on your next roof, we recommend considering standing seam metal to make the most of your investment.

Whether you choose corrugated metal, standing seam, or something else entirely, a professional roofing contractor can help you get the ball rolling. See how much your next roofing project will cost in just a few clicks.

Fixr.com provides cost guides, comparisons, and term cheat sheets for hundreds of remodeling, installation and repair projects.

Advantages Of Aluminum Roofing

In most residential cases, the slope of the roof covering the home isnt a concern because they are built specifically for traditional shingles. No matter the slope, metal roofing offers the best long-term protection for your home. In terms of longevity and variety.

Mountaintop Metal Roofing materials and installation are made to stand the test of time. With little to no maintenance, this is truly a set it and forget it upgrade. We offer a lifetime warranty with every project. Non-prorated and transferable, were confident youll never have to worry about your roof again.

Mountaintop Metal Roofing offers a range of products from Permalock, one of the most trusted roof manufacturers in the industry. From smooth, woodgrain, and slate shingles to cedar shake and standing seam profiles, we have the look youre, well, looking for. With more than 200 colors to choose from and different finishes, we will be able to match any architecture.

In the market for a new roof, whether out of necessity or to improve the look of your home, contact Mountaintop Metal Roofing for a free estimate. Unlike other roof contractors, aluminum roofing is all we do. When working with us, you can be confident that the job will be done right the first time.

Read Also: Will My Roof Support Solar Panels

Disadvantages Of Metal Roofs

Despite their many advantages, metal roofs have some potential drawbacks.

- Affordability. Metal roofs can be as much as two or three times more expensive than other roofing materials. While the life of a metal roof is much longer, investing in a metal roof only makes sense if you plan to stay in your home long enough to enjoy the cost benefits.

- Noisiness. Metal roofs may be more noisy during a heavy rain or hailstorm than other products depending on the type of decking used during installation . Adding more attic insulation can sometimes solve this problem, but that may increase costs.

- Expansion, contraction and fasteners. Metal roofing material assemblies that are attached as large panels are designed to expand and contract as they warm and cool. However, both exposed and concealed fasteners have varying lifespans. Depending on the climate, neoprene washers and the screws used during installation may degrade and become dislodged over time.

- Inconsistency of color match. If a repair is required or a home extension is added years later, it may be difficult to find an exact match to the existing metal.

- Performance. If water accumulates anywhere on the roof because of poor-quality installation or repair, it can eventually cause serious damage. Low-grade metals may also be thinner gauge and less durable. Some metals rust in certain climates or dent more easily than others during hailstorms or installation.

What Types Of Roofing Sheets Are Available

Whichever roofing sheet you choose will boast its own series of benefits, and the right one for you depends on your budget and the structure youre roofing. Weve got an excellent roofing sheets buyers guide which goes into our range in more detail. But if you want to stick around, heres a quick run down of the main types available and how to use their calculators:

Don’t Miss: How Much Does The Tesla Roof Cost

How Do You Seal The Ends Of A Corrugated Roof

To seal the ends of a corrugated roof, you will need to insert a tube of butyl caulking into a caulk gun and then snip the end of using sharp scissors. Once this is done, you must apply a 1/4-inch wide bead of caulk over the seam where the two panels overlap.

Once you have done this, you will need to work your way across the entire roof to apply caulk to all remaining seams in order to seal them.

Are Roof Coatings Any Good

There are legitimate roof painting companies out there who are very good at what they do. They do not make outrageous claims about what their service or product will do for your roof. Genuine roof painting companies can do an excellent job of cleaning your roof and painting it the color you require.

You May Like: How Much To Charge For A Square Of Roofing

Corrugated Steel Metal Roofs

Corrugated steel metal roofing sheets come with a built-in, natural gray finish. Though some homeowners like the industrial look, changing the color of the sheets with paint can be challenging. Corrugated steel roofing is more expensive than aluminum roofing.

Roof Installation Cost Calculator

How Does The Gauge Of The Steel Affect The Corrugated Roofing Cost

There are lots of options when you are choosing the gauge or thickness of corrugated metal roofing. The gauge of the steel can be a bit confusing as a lower gauge is actually heavier steel. For example, 24 gauge is heavier than 26 gauge steel.

The vast majority of corrugated roofing is either 24 gauge or 26 gauge. Either gauge is appropriate for a corrugated roof. However, if you want a PVDF paint system then you must purchase a 24 gauge. If you would like a 26 gauge roof then it would only be available in a SMP paint finish. Corrugated roofing in a 24 gauge vs 26 gauge will add 25% to 35% to the price.

The lightest gauge that you can purchase is a 29 gauge corrugated roof. It is our opinion that 29 gauge is a bad investment. The 10% material savings vs the overall installed price of the roof just does not justify the lighter gauge.

If you have further interest in this subject we suggest that you read: What Gauge Metal Roofing Should I Use For My Corrugated Roof?

Also Check: Will Baking Soda Kill Moss On Roof

Minimum Slope For Asphalt Shingles

The requirements for an asphalt shingles roof are contained in the International Building Code. According to this code, the minimum slope for asphalt shingles is 17 degrees or two vertical units to twelve units in the horizontal.

In case a slope greater than this is necessary, then a double underlayment application must be used as per the requirements of the International Building Code.

How Do I Verify Measurements For My Metal Roof

Are you a do it yourself person or a contractor thats familiar with shingles but new to metal roofing? If thats you, or if you just want to answer the question How do I verify measurements for my metal roof then this vlog post is definitely for you!When it comes to figuring materials for your roof it all starts with a sketch. And over the years Ive seen all sorts of sketches. Ive seen them range from a doodle on a napkin to full-blown architectural drawings.

Recommended Reading: What Is The Cost Of Tesla Solar Roof

Also Check: How Long Does A New Roof Take To Install

Minimum Roof Pitch For Shingles

It is important for shingle roofs to function properly, and one method of ensuring that this is achieved is to observe the pitch requirements for the shingles.

The recommended minimum roof pitch for shingles is 2/12, or simply two units of vertical rise to every twelve units of horizontal span.

However, it is regrettable that many installers usually ignore this requirement due to the desire for a quick installation process. However great a shingles roof installation might look, if the minimum slope requirement is not observed, there are no guarantees that it will last long, let alone serve its purpose correctly.

The Process Of Purchasing Metal Roofing From A Manufacturer

The process of purchasing metal roofing is different depending upon the type of vendor that you will use. Purchasing metal roofing through a distributor, supplier, or roofing contractor is simple. Basically, you pay them a premium to help you figure out what exactly you need. But what does the process look like for you if you purchase metal roofing directly from the manufacturer?

The main disadvantage when purchasing directly from the manufacturer is that you need to know exactly what you need. Its the homeowners responsibility to provide the manufacturer with a take-off or materials list.

This is a list that contains the materials needed for your job such as: how many panels, sheet lengths for each panel, list of trim and flashing pieces, the pitch of your roof, metal roofing underlayment, and accessories.

If you generally know what you need, but require a little help and guidance, then a manufacturer will typically provide enough help to bridge the gap. At Western States Metal Roofing, we are always happy to answer basic questions and steer our customers in the right direction. However, if you have no clue of whats required and you cannot provide a materials list or take off than you have four choices:

Don’t Miss: Does House Insurance Cover Roof Leaks

S To Estimate Metal Roofing

Measure the length and width of each roof section in feet, then multiply together to get the square footage.

If you are unable to crawl on the roof, you can estimate by measuring the roofs footprint and finding its square footage. Multiply the footprint square footage by the multiplier for your roof pitch to find the actual square footage of the roof. Use our to find the pitch of your roof.

Next, find the square footage of the metal roofing panels you want to use. Measure the length and width in feet, then multiply together to find the square footage. Panels are often measured in inches, so you can use our to convert to feet.

Finally, divide the square footage of the roof by the square footage of the metal roofing panel to find the number of panels needed for your roof. Its a good idea to order an extra 10% to account for cutoffs and waste material.

For more complex roofs with many peaks and sections, find the square footage of each roof section and add them all together to find the total square footage. Consider ordering a few extra panels to account for more cuts and waste.