Minimum Pitch For Corrugated Metal Roof

by Mountaintop Metal Roofing | Sep 10, 2020 | Residential

For the most part, there are two types of roofs: pitched and flat. Used mostly for industrial, commercial, or manufacturing facilities, flat roofing choices arent as plentiful as pitched roofs. Made mostly of bitumen, rubber membranes, or even tar, these roofs have a very slight slope to ensure the water drains away.

There cant be any spaces, seams, cracks, etc. or else water will find a way through. Ponding is a huge issue, although some flat roofs drain to the middle of the roof to a drain system. There are some residential flat roofs, but slope roofing is much more common.

With pitched roofs, taking water away from the home is a much easier proposition. The steeper the slope, the easier it is for rainwater and other precipitation to find its way to the gutters. If it isnt a very steep slope, water may not drain away as well, causing issues.

When choosing a roofing covering, its important to know what the slope of your roof is. Although different jurisdictions may have different regulations, even flat roofs must have a general slope of at least ¼ inch rise for every 12 inches. From there, different roof surfaces need different slopes.

For aluminum shingles, the slope reaches 3 inches for every 12 inches. There are more seams and fasteners with shingles, so it makes sense to have a steeper pitch than with the panels. However, this slope can be minimized if additional sealants or special underlayments are used.

A Maintained Skylight Is A Clear Light

Proper skylight maintenance doesnt end with installation. We recommend keeping your skylight clean and clear with regular check-ups and maintenance throughout the year. Keep an eye on the ceilings, floors and walls in your skylight room for possible leaks or damp spots. Any water residue found could indicate a leak in the skylight and possible build up of mold. Also be sure to dust your skylights from the inside and cleaned on the outside to ensure clear window viewing.

What Type Of Screw Gun Should I Use To Fasten Metal Roofing Panels

Use an actual screw gun with an adjustable clutch and a depth sensing control feature. Screw guns are designed so that you can adjust the torque which will help eliminate over tightening of the screws. In addition, use a variable speed screw gun which will permit you to change the speed.

If youre a homeowner and its just too expensive to purchase a screw gun for a one time installation there is a solid second option. A variable speed and adjustable driver will still get the job done and you may even already own one of these.

Don’t Miss: Skylight Metal Roof

Drive Screws Just Right

- Fastening the panels just right is the key to a watertight roof. Here is what you should know:

- At the eave, place screws on both sides of every rib and lined up to go through the foam closure strip.

- Each row should be spaced no more than 24 inches with one screw at each rib on the overlapping side.

- Start at the bottom, fastening across the panel in rows, working toward the ridge.

- Drive screws to seat flat on the roof a crooked screw wont seal.

- Dont over-tighten or under-tighten. Tighten just enough to compress the rubber gasket to the edge of the screw head, not past it.

- Clean up any metal shavings or burrs right away. They will rust.

How Much Will It Cost To Install A Metal Roof On Your Flat Roof

Pricing is the biggest factor homeowners account for when deciding if they should get a metal roof over their flat roof. Unfortunately, its impossible to give you an exact price without a roof inspection.

However, I can at least give you a rough estimate for the price of each type of metal roof based on square footage.

A screw down panel metal roof starts around $4.50 per square foot. A screw down metal panel will be the cheaper option, but youll end up spending money on the maintenance it requires.

For a flat roof with no penetrations, you can expect a 24 gauge steel standing seam metal roof to cost around $12.00-$15.00 per square foot. This number could be more or less depending on the size of your flat roof, the roofing contractor you hire, and other factors.

However, its a good number to give you an idea of the budget youll need for a standing seam metal roof.

Don’t Miss: How Many Screws Per Square For Metal Roofing

Overtightening Or Undertightening Can Both Result In Leak Points

Sinking screws to fasten a metal roof doesnt sound like a very complicated process, so many well-intentioned folks just assume they can take on metal roofing installation as a DIY project. The problem with this assumption is that if you dont have particular training and experience in this area, you could end up doing more harm than good. One of the most common errors revolves around overtightening or under-tightening the screw fasteners.

Most err on the side of overtightening. Its a natural reaction to simply try and sink the screw as far down as it will possibly go. The tighter the screw, the more secure it must be, right? Unfortunately, no. The problem with this approach is that it overcompresses the washer and creates too much stress. This will cause the washer to fail prematurely, or worse, you could break the washer right from the start. Overcompressed or broken washers can easily result in leaks.

You dont want to overtighten, but you really dont want to under tighten your screws either. A screw thats underdriven doesnt create a proper seal for the washer, and that can results in leaks, too. If you can still spin the washer after youve put in your screw, thats a good indication that the screw is still under tightened. A professional installer is able to avoid both extremes by utilizing a specialized screw gun which is set to exact speed and/or torque specifications for metal roofing gasket fasteners.

Roof Space Available For Solar Panels

One obvious factor to be taken into consideration when mounting panels on a roof is the amount of space available on it. A typical polycrystalline or monocrystalline panelmeasures about 1.6m x 1m, and depending on the capacity of your system, for an average 2 or 3-bedroom home, you should be able to fit enough panels to significantly offset your electricity costs on one, or in a stretch, two parts of your roof. Closeness of the panels to your home is not an absolute requirement: the roofs of sheds, garages, and balconies that stand slightly apart from your house may also provide options for placement.

You May Like: How Do You Get Rid Of Moss On Your Roof

Read Also: How Often Does The Roof Need To Be Replaced

How Is Corrugated Metal Made

Corrugated metal roofing is either made from galvanized steel or aluminum. The panels are manufactured through a process called roll forming.

First, plain sheets of metal are put in a machine that has rolling dies. The rollers then shape the metal to create round and wavy panels. Afterward, the excess length is sheared off to get the desired panel length.

Corrugating metal gives it considerable structural strength. If you want panels with different shapes, all you have to do is change the rolling dies.

Snap A Square Reference Line

- A square reference line is important for installing roofing panels evenly. Use the 3-4-5 method to establish a reference line 90 degrees to the eave.

- First, make a mark along the eave three feet from the corner. At that mark, measure four feet toward the ridge. Then, from the original corner, measure five feet and mark where it intersects the second mark.

- Snap a line from the first three-foot mark through the intersection of the second and third marks. Since the Getaway roof is larger, I measured to 21 feet, 28 feet and 35 feet to make my square reference line.

Recommended Reading: How Much Roof Overhang On Shed

Is The Company Licensed

When looking for doctors to treat your ailment, there is a high chance that youll be on the lookout for top doctors who are specialists in the area of your interest. The same rule should apply to your search for a roofer. Look for a roofer that has a license to practice in your state. Also, make sure that the roofer is registered with the local roofers association.

What Is The Right Screw Gun Speed Setting When Installing A Metal Roof

In order to avoid installation errors, have your screw gun set to the correct drill speed settings. The correct speed for the drill depends on the substrate and screw type.

- Use a 2,500 RPM screw gun for wood and steel substrates that are less than 1/4-inch thick.

- Use a 2,000 RPM screw gun for steel substrates that are 1/4-inch thick and heavier.

- Use a1,000 RPM to 2,000 RPM screw gun for 304 stainless steel screws.

Once you have your tools and know your fastener type, quantity, and panel youll be working with, you can prepare for the installation of the fasteners.

Watch our fastener installation video for proper installation:

To see how screws are placed on a corrugated panel, watch this video:

You May Like: How Many Screws Per Square For Metal Roofing

Corrugated Metal Roofing’s Width

The width is measured from one edge of the panel to another without following the ridges and grooves. Different corrugated panels will vary in size, but the most common widths are 26 and 36 inches. Other popular standard widths include 24 and 39 inches.

When measuring the roof coverage, remember each panel will overlap the other by two grooves. For instance, a 39-inch panel will only provide a roof coverage of 34.67 inches. Similarly, a 26-inch panel will only cover 21.33 inches.

Three Big Differences Between Corrugated Metal Roofing And Standing Seam Roofing

The three key differences between corrugated and standing seam metal roofing are:

Each material offers its own mix of benefits and drawbacks.

Read Also: Corrugated Roofing Overhang

Metal Roofing General Information

Metal roofs are often made of steel or aluminum, but zinc is also a popular option.

Some metal roofing requires standing seam panels while other types can be installed with just interlocking pieces and screws.

The roofing material is usually made with a corrugated metal profile and the panels are attached to special clips or tracks.

Standing seam roofs require two people for installation, but most other types of metal roofs can be handled by one person if you have help installing the rafters.

Engineered To Expand & Contract With Ease

All roofs undergo some serious temperature extremes, and any roofing material has to endure expansion and contraction cycles.

Standing seam metal roofs are perfectly suited for this challenge. The raised metal seams interlock for effective water protection, but they can also float on their clip mounts as temperatures rise and fall.

Don’t Miss: How Much Is A Shingle Roof Per Square Foot

Solar Panels Can Maximize The Cooling Benefits Of A Metal Roof

Homebuilders and contractors often tout the benefits of cool metal roofing to keep your home cool in the summer and reduce your energy use. Metal roofs reflect more sunlight than traditional black asphalt shingles, and some also have reflective paint to increase this effect. Installing PV solar panels can take your electric bill savings a step further simply by shading the roofs surface.

Read Also: What Plywood Do You Use For Roofing

Skylights And Hail Damage

While glass manufacturers continue to make advances in impact resistance, hail remains a challenge. Plexiglass is the worst choice when it comes to hail resistance, as it may scratch and will break much easier than glass. Tempered and laminated glass resists small and medium hail quite well, but there is always the possibility of abnormally large hail breaking through a roof skylight. When that happens, skylight repair or replacement are your only options.

But skylight repair doesnt have to be expensive. Some skylight manufacturers offer warranties that cover hail damage, and home insurance can provide you with an additional layer of protection.

You can also use exterior skylight covers to protect skylights from hail. For example, wire cages may defend acrylic skylights, though they may spoil the view. It is ideal to have the covers or shades produced by the manufacturer so that they wont void the overall warranty on the product.

Recommended Reading: Cutting Roof Trusses

Advantages Of Aluminum Roofing

In most residential cases, the slope of the roof covering the home isnt a concern because they are built specifically for traditional shingles. No matter the slope, metal roofing offers the best long-term protection for your home. In terms of longevity and variety.

Mountaintop Metal Roofing materials and installation are made to stand the test of time. With little to no maintenance, this is truly a set it and forget it upgrade. We offer a lifetime warranty with every project. Non-prorated and transferable, were confident youll never have to worry about your roof again.

Mountaintop Metal Roofing offers a range of products from Permalock, one of the most trusted roof manufacturers in the industry. From smooth, woodgrain, and slate shingles to cedar shake and standing seam profiles, we have the look youre, well, looking for. With more than 200 colors to choose from and different finishes, we will be able to match any architecture.

In the market for a new roof, whether out of necessity or to improve the look of your home, contact Mountaintop Metal Roofing for a free estimate. Unlike other roof contractors, aluminum roofing is all we do. When working with us, you can be confident that the job will be done right the first time.

Are Skylights Out Of Style

We dont think so! Depending on the architectural style of your home, skylights can add a good deal of aesthetic appeal, illuminating the interior with gorgeous natural light. In fact, skylights are making a comeback, as many people are discovering or rediscovering their beauty.

That said, a common worry about skylights used to be that they are not very efficient. Fortunately, skylight technology has come a long way. Not only are todays skylights more energy efficient than they ever used to be, but some Velux models come with built-in solar panels, for eco-friendly energy use, and sensors that enable them to close at the first sign of bad weather.

Also Check: How To Build Gable Overhang

There Are Two Main Reasons Why Corrugated Roof Sheeting And Low Pitches Do Not Mix:

Flat skillion roofs are the most common way to increase the size of a traditional bungalow house and many builders and roofers simply slapped on some corrugated iron for the roof. This is the cause of most of the roof leakage problems with skillion metal roofs.

Modern architecture has birthed the demand for low profile roofs and builders and roofers still have a problem in this modern era of simply not understanding the limitations of corrugated roofing. I see countless examples of corrugated roofing on brand new low pitched roofs. These are water leakage time bombs. and many roofers think they can fix these roofs with a bit of roofers silicone until they find that roofers silicone is not always the way to do a roof repair properly.

UPDATE:

Answer to a smart question: As a roof gets longer, does the slope need to increase?

Lay And Secure The First Metal Panel

When laying the metal, you will need to start from the bottom corner of the roof and work across. After you have finished each row of panels, you will then need to start a new row that overlaps the old row by at least 4 inches.

You can think of this process as moving across the bottom of the roof and then progressively getting higher and higher until you reach the peak.

When you start with the first metal panel, position it so that it overhangs the edge by at least 4 inches. Now slide a washer onto a 1 ½-inch wood screw and use your screwdriver to secure it to the plywood of the roof.

As a rule of thumb, you want it to be tight enough to hold it in place, but not so tight that youâve dimpled the metal. Then, add screws approximately every 8 inches along the outside edge and bottom of the panel.

You May Like: Attic Trusses Cost

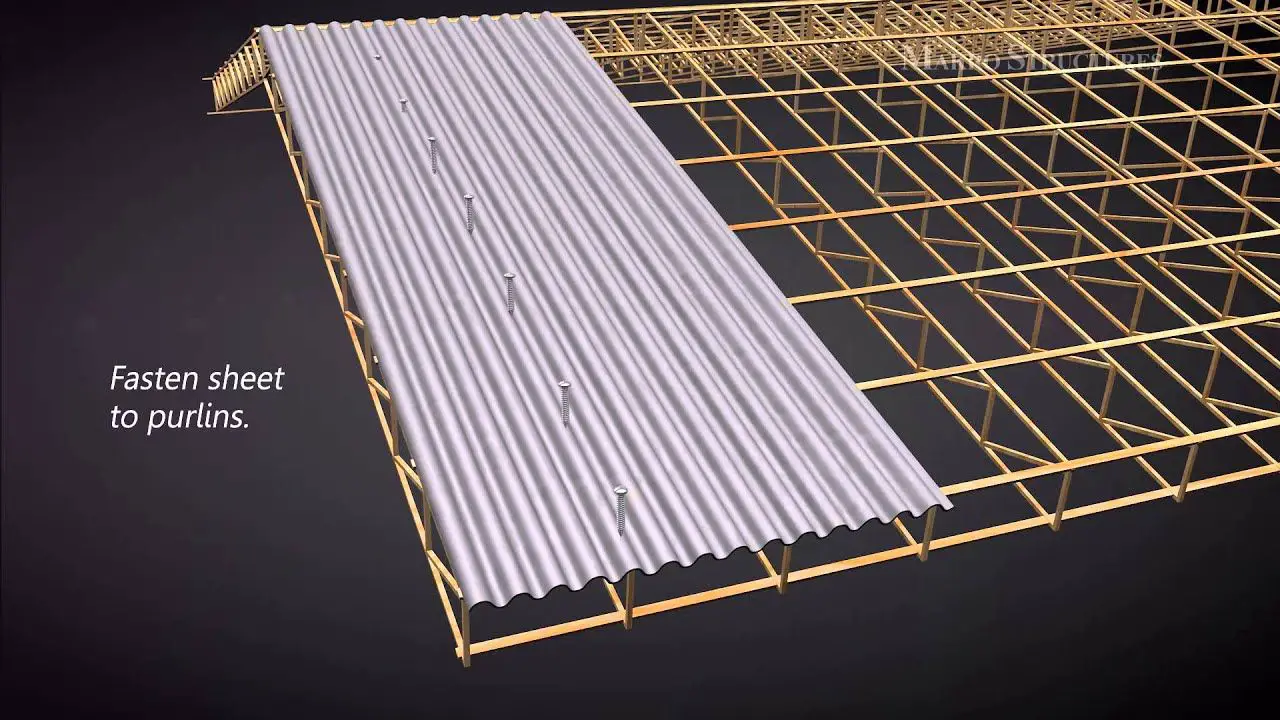

How To Install Corrugated Metal Roofing Panels

You will need to square your roof before you begin installing the metal sheets. Discover how to use the 3,4,5 triangle method.

After the roof is square we will show you how to install the first corrugated panel, how to overlap your panels, and fastening the panels.

Screw location is a critical component of a corrugated metal roofing installation.

- Do the screws go in the panel high or low? Why?

- Where are the fasteners located?

- How many screws do I need?

- How do I overlap the corrugated?

This video answers all of these questions.