Where To Use Epdm

EPDM hasnt replaced on all my jobs, but I use it for flat or low-slope roofs, and primarily on roofs that cant be seen from the ground. I tell customers that EPDM makes the ugliest roof theyll ever see but that they wont see it. Typically, a flat roof on a one-story addition can be seen from a second-floor window, but thats it. On rooftop , EPDM can be covered with a wood deck on pressure-treated sleepers, with outdoor or Astroturf, and even with concrete pavers. EPDM can also be painted with Hypalon paint, but the paint will have to be recoated every three or four years.

Mechanically Attached Epdm Systems

Mechanically attached EPDM is attached using seam plates and roof fasteners dispersed across the surface area of the roof. These fasteners are screwed into the EPDM membrane in order to secure it to the roof. Fasteners are penetrations in the roof membrane which can sometimes be a cause of water issues and leaks if they are left exposed. However, many mechanically fastened EPDM roofing systems account for this and include a way to cover these potential penetration points.

Different Types Of Rubber Roofing

A rubber roof is, you guessed it, a roof made of rubber materials. But its much more complex than that. There are actually many types of rubber roofs, each with its own benefits, disadvantages, lifespans, and installation methods. Today well walk you through each and help you determine which is best before tackling your DIY install.

Recommended Reading: Overhang Extension

Quick And Easy To Install

When it comes to EPDM roofing membrane installation, this material is both quick and easy to install for EPDM roofing companies. This is due to the fact that its manufactured in large sheets or rolls. Instead of placing each shingle at a time, you can simply roll out the EPDM and cover more area faster.

Modified Bitumen And Built

Modified bitumen is also known as roofing tar, and its a popular choice for flat and low-sloped roofs.

Modified bitumen systems can be applied as a self-adhering compound or using torch-down application. It is also used in built-up roofing systems.

Modified bitumen and BUR roofs tend to have a shorter lifespan than rubber roofs, and they dont offer the same energy-saving benefits.

Also Check: Shed Eave Overhang

Lay The Rubber Roofing

Now that your insulation is laid down, you can begin laying the rubber roofing. As mentioned earlier in this guide, different types of roofs require a specific installation method. But generally speaking, for all methods, lay out the sheets and pull them taught over any ridges or valleys to create a tight seal across the entire surface area before securing it into place.

Forget The Mess Of Asphalt Roll Roofingfor Flat Or Low

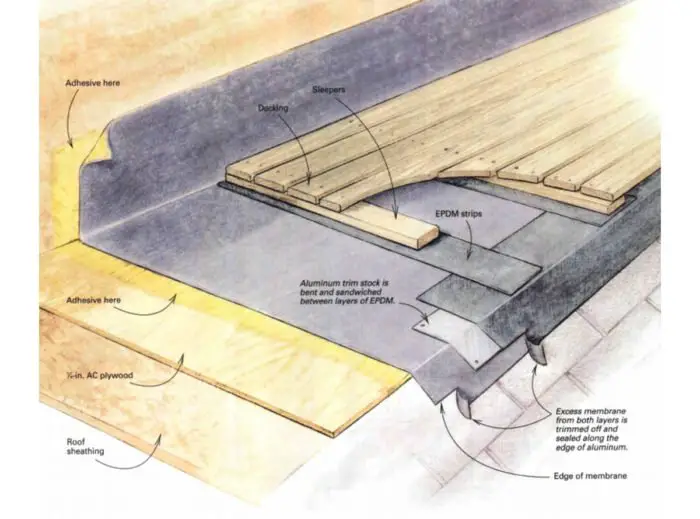

Synopsis: This article explains how to install a low-slope roof made from EPDM, a synthetic rubberlike material with many advantages over more conventional asphalt materials. Basically, the roof is glued to a substrate. But details count.

Not long ago, wed cringe whenever wed get a job that had a flat roof or a roof with a really shallow pitch. Add a couple of extra details such as a 6-ft. French door opening onto a wooden deck over the roof with kneewalls on two sides, and wed hear voices screaming in our sleep: Im going to leak, Im going to leak.

The only way we could guarantee a watertight job was to have a copper roof pan fabricated to cover the flat part of the roof. But copperwork aint cheap, and wed still have to do some fancy flashing. In most cases we were forced to fall back on that old inferior standby, roll roofing. Because of roll roofings poor track record, we always left the homeowners a bucket of tar at the end of the job. Eventually, theyd need it.

EPDM membrane is sold by the yard

There are many different systems for installing EPDM membranes, including loose-laid and ballasted mechanically fastened, hot-applied fully adhered and fully adhered. Each system has different performance characteristics that make it suitable for specific applications.

To read the entire article, click the View PDF button below:

Sign up for eletters today and get the latest how-to from Fine Homebuilding, plus special offers.

Read Also: Skylight Metal Roof

Should I Consider Rubber Roofing For My Home

If you have a low-pitched home, consider rubber roof installation. This choice is also ideal if some part of your property accumulates water or ice dams during cold weather. Since determining your homes pitch may be tricky, consult residential roofing experts before choosing this material.

With their help, you can determine if installing rubber roofing will protect your home from water damage. These experts also guide you in choosing a suitable underlayment.

How Much Does Epdm Rubber Roofing Cost

The most up to date pricing for our products is available by following the links in the section below.

Although EPDM rubber roofing systems can be a little more expensive than its alternatives, the return on your investment is significantly higher. The cost for professional installation will depend on the total square footage of the job. The complexity of the roof itself will also factor in. Smaller, straightforward jobs can be completed quickly and easily at a more affordable rate. Larger, bespoke projects will be reflected in the cost.

Fix-R EPDM Membrane

As a rough guideline, we would estimate that a professional company would charge between £60-£80 per square metre. This is not factoring in the VAT, labour costs, disposal and any scaffolding required to complete the job.

If you have the experience to install the rubber membrane yourself or wish to purchase the materials for someone else to install, it helps to know the costs involved. A high-quality membrane is essential and Fix-R EPDM Membrane provides just that.

Youll also need an adhesive, which Fix-R EPDM Water Based Acrylic Deck Adhesive offers the perfect solution for. Fix-R EPDM Bonding Adhesive is ideal to use around the edges of the roof, or in more complex areas where bonding may prove to be an issue.

BUY ONLINE NOW

Read Also: Large Overhang Roof

Things Youll Need To Install Rubber Roofing

Now the fun parthow to install your own rubber roofing. Because many rubber roofs might have a lower lifespan compared to other roofing materials , it can save a lot of money by knowing how to DIY rubber roofing repair and replacement.

So today, well walk you through the steps to get it done right the first time. Of course, if you doubt your abilities and instead have the pros take care of itcall Gouge Roofing.

What Are The Benefits Of Epdm Rubber Roofing

EPDM rolls are large and lightweight, allowing them to cover more area in a shorter time for quick installation. This ultimately means a lower bottom line price for customers. While structural failures are uncommon, the design of rubber roofing makes repairs somewhat simple compared to other materials such as shingles or metal roofing.

Recommended Reading: How Do I Know If My Roof Is Leaking

Is A Rubber Roof Easy To Install

Installing a rubber roof is relatively easy compared to fixing other traditional materials like clay. Still, its always best to get these services from a professional. This precaution will help you avoid wasting materials after an incorrect installation. It also prevents accidents and physical injuries while ensuring you achieve a seamless look.

How To Install A Rubber Roof:

How to install rubber roofing on flat roof. Roll out the rubber membrane. The rolls are applied to a completely cleaned, stripped roof deck that has been coated in adhesive. Align the first metal roofing panel so that it overlaps the edging by 1/2 to 3/4 of an inch and is square to the roof line.

The thickness of said material and whether the installer fully adheres , mechanically fastens , or uses ballast , also plays a role in pricing. Be sure the larger edge is laid so that. Make sure it is clean and clear of all debris.

Ensure the glue does not exceed 150 mm at the adhesive point for the. After 30 minutes, fold the lower half of the rubber strip on top of the upper section and clean it with a broom over the exposed rubber and roof. On the rubber strip of your roof, make sure that your material adheres.

Rolls, although some manufacturers offer various lengths and widths. Roll the epdm membrane back in to position immediately whilst the adhesive is still wet. The rubber has to be cut away in order to accommodate these.

This video shows you the basic steps involved in a fully adhered epdm roof, sometimes known as the classic bond. The rolls are cut to fit, then unrolled across the roof and smoothed out to avoid air bubbles. Allow the adhesive to dry slightly, unfold the rubber back onto the roof and then push out any air bubbles with a push broom by going over the entire surface.

Starting from one side of the roof, roll out the materials of the rubber roof.

Read Also: Travel Trailer Roof Repair Kits

How Much Does A Full Roof Replacement Cost In The Uk

Getting a full roof replacement will vary a great deal depending on the location and the roof type. The UK national average cost to replace a roof is £5,500 with most homeowners spending between £3,000 and £16,300. Roof installation cost ranges from £300 to £380 per square meter depending on the roof size and materials used in roofing.

Epdm Roof Maintenance And Cleanings

Like any other roofing material, EPDM roofs may require occasional maintenance and repairs. The good news is that repairs for rubber roofs are normally quick and inexpensive. Applying special tape or liquid rubber may be all thats needed to fix a leak.

Also, the maintenance needed is minimal compared to other roofing types. Some EPDM roofs require no maintenance other than an acrylic paint job once every decade. This is recommended to keep the color of the roof vibrant throughout its lifespan.

Cleaning should be done along with an inspection about once a year. The roofs should be kept clean and free from debris.

Don’t Miss: How Often Should A Roof Be Replaced

Epdm Roofing Installation Info

One of the primary benefits of EPDM rubber roofing is ease of installation. Since EPDM is easily installed with large sheets, it is far less labor intensive than conventional roofing methods. We recommend the âfully adheredâ method of installation. Simply use Roof-Top® bonding adhesive to adhere EPDM to the underlying surface.

For easy step-by-step instructions on installing your EPDM rubber roofing, please review the installation instructions below and/or order our installation DVD. For additional information, please feel free to contact our knowledgeable and experienced sales staff at 630-7660.

Bond The Membrane To The Roof Deck

This roof was 3.5×4.0 metres with a relatively shallow roof slope. The roof was asymmetrical, the front cantilevered section was relatively short in comparison to the longer slope at the rear. The shallow slope meant that I felt comfortable walking on this roof to install the membrane.

I started to install epdm roofing on the short front section of the roof first. To do this I folded back the front section of the roof membrane. And started the glue application process by pouring a good dollop of glue into the paint tray.

Glue and roller, ready to start application of adhesive

The glue loaded well on to the roller and it was easy to get an even layer over the whole front section of roof . I then flipped back the section of the membrane that I had folded back, on to the glued area. I smoothed out the membrane over the glued section using a ‘soft’ broom. This had the function of getting rid of any air bubbles between the deck and the membrane. Also, the pressure from the brush helped to create contact between the membrane and the roof so increasing the bond between the two.

Application of glue to the front section of roof

With the front section complete. I repeated the process to install epdm roofing on the rear slope of the shed.

Ready to start application of glue to the rear section

Unfolding the membrane over the glued rear section of the roof

Completed section of rear roof, with yellow brush handle visible

Don’t Miss: How To Repair Roof Trusses

Contact Absolute Construction For High

Installing rubber roofing is the ultimate way to enjoy reliable protection for an extended period. Getting these services from an expert will simplify identifying an ideal design and color.

At Absolute Construction, we offer residential rubber roof installation and repair services. Our experts can also recommend maintenance practices to preserve your homes aesthetic and protect it from water damage. Contact us for an estimate if you want high-quality rubber roofing services.

What Is A Rubber Roof

A rubber roof, or membrane roof, is a durable, low-maintenance alternative to traditional materials like asphalt shingles.

Rubber roofs are typically found on commercial buildings, warehouses, garages and other industrial sites where conventional roofing materials are not ideal.

Typically made of EPDM Ethylene Propylene Diene Monomer a synthetic rubber that is resistant to ozone, ultraviolet light and aging. The roofing material is then molded into shingles or sheets.

While most roofs are built with layers of felt paper, asphalt and shingles on top, a rubber roof consists of a single sheet of EPDM membrane glued to the surface underneath.

Because this material is a single layer, it does not have seams that can trap water or moisture.

Compared to asphalt shingles, rubber roofs are more durable and offer better insulation from temperature extremes.

Rubber roofings long lifespan means lower maintenance costs throughout its lifetime. In addition, EPDM becomes softer in hot weather and stiffer in cold weather, so it wont crack as asphalt shingles commonly do.

You May Like: Should I Replace The Screws On My Metal Roof

How To Fitting Epdm Membrane

For fitting the EPDM membrane properly on the roof, it should be trimmed at the required. After that according to the required roof dimension trimmed the membrane and installed it on the roof.

Before installing the membrane on the roof, you have to ensure that the cutting part of the membrane did not cut too large or too short. In this way, you can fit the EPDM membrane on your roof.

The Pros And Cons Of Single

Before installing rubber roofing, its advisable to learn more about its pros and cons. This way, you can weigh their costs against benefits and make an informed choice.

One significant advantage of rubber roofs is that they are an affordable option. Compared to other choices, they are also relatively lightweight, reducing labor and installation expenses. They also need less repair and maintenance, allowing you to save more in the long run.

Other pros of rubber roofing are:

- They improve curb appeal

- High resistance to water damage

- Fire resistance

- Environmentally friendly

Despite rubber roofs having many benefits, they also have some cons. For example, the installation process requires dry conditions for proper attachment. Hence, when planning to get rubber roofing, its advisable to do it during summer or fall.

Another drawback about rubber roofs is that they are prone to punctures. Still, you can prevent this issue by trimming tree branches hanging over your property. Besides, avoid mounting objects like satellite dishes on the surface or hire an expert for the process.

Also Check: Skylight Installation Metal Roof

How To Install Epdm Rubber Roofing

EPDM rubber roofing installation is a very easy process and it is widely used nowadays. EPDM rubber roofing is a type of roofing that is installed with large sheets. EPDM rubber roofing process is a step-by-step process that provides rubber roofing to protect your flat roof.

This type of method is a fully adhered method where an adhesive material is used to bond together. There are have many steeps and required experience to avoid many mistakes that cause damage to the roof.

The steeps are showing below.

- Prepare the roof deck.

- Apply the finishing touches.

How To Install Rubber Roof Yourself

Whether it is a flat roof or pitched roof, a rubber roof is a great choice to ensure against leaks from rainwater or snow. When water sits on the roof, it is easy to find ways to come into the roof structure. A rubber roof will prevent this leak by making the water goes down the roof.

Read Also: Roofing Costs In California

Widths Ranging And Thicknesses

EPDM roofing systems are sold in a variety of widths and thicknesses to help meet any homeowners needs. Its widths range from 7.5 to 50, and its thicknesses are available in 45 mil , 60 mil , 75 mil and 90 mil . The roof can be attached through adhesives, ballasting, or mechanical attachment. Its good to know that the thicker material you choose, the longer your roof is designed to last. The average lifespans for each thickness include:

- 45 mils About 12 years

- 60-75 mils About 12-17 years

- 90 mils At least 25 years

EPDM should be installed by professional roofers. Contact us today to schedule a free consultation.

Cost To Install A Rubber Roof

Many homeowners make the mistake of assuming that flat roof installation and work is less expensive than pitched roof work. After all, flat roofs are much less complicated to access, and its a lot easier to move around on a flat surface than on a sloped one. We have some tips on hiring a flat roofing contractor for your convenience.

However, many roofers will attest to the fact that working on flat roofs is more physically taxing than working on steep ones. Flat roof work may not call for a harness and brace system, but it does involve more stooping, bending, and lifting than pitched roof work.

Additionally, flat roofs require more elaborate installation processes that involve the handling of adhesives and the use of sophisticated application techniques.

For these reasons, installation and labor costs for a flat roof can be as high asor higher thanthose of a pitched roof.

Rubber roofing materials are typically more expensive than traditional composite shingles, as well. However, a rubber roof will last longer and offer more benefits than asphalt shingles or asphalt roll roofing.

Recommended Reading: Shed With Overhang Roof