How Do I Know What Size Purlins I Need

A purlin is one of the most important tools in architecture. This is a horizontal beam that provides structural support in buildings, typically the roof. Purlins themselves are usually supported by the walls of the building. While they are commonly used in metal buildings, they are sometimes used in structures that have a wooden frame. Purlins come in different types and sizes. Therefore, it is important for you to use the right purlin.

What Is The Purlin Spacing For 26 Gauge Metal Roofing

The purlin spacing for 26-gauge metal roofing is 4.5 feet. Youll note that this is slightly larger than the recommended spacing for 29 gauge metal roofs. The reason is that 26-gauge metal roofs are a lot heavier than their 29-gauge counterparts. Heavier metal roofs dont need as much support as lighter alternatives.

Q What Is A Purlin And What Does The Purlin System Do

A purlin is a roof framing member which is installed perpendicular to rafters. Traditionally purlins were used in heavy timber framing but have been replaced by plywood sheathing in most modern houses. We use true 1x4s installed directly on top of the existing shingles and spaced at 24 as seen below.

The purlin system has 3 major benefits: Insulation/airflow, strength and sustainability. By installing purlins on top of shingles we keep a lot of waste out of the landfill and we are able to recycle our metal scraps . Purlins add strength to the existing roof and can also be shimmed to visually eliminate sagging sections of old roofs. Finally By installing the purlins and then metal we create an air gap that allows the metal to act as a radiant heat barrier. The ribs in the metal also act as natural vents, allowing hot air to flow up and out at the ridge vent, drastically reducing attic heat in the summer while retaining some heat in that air pocket in the winter!

Read Also: How To Figure Square Footage For Roof Shingles

Do Metal Roofs Need Furring Strips Underneath

Furring strips are best described as long, slender strips that are constructed from wood or metal. Theyre usually 1 x 2 or 1 x 3 in size and can be applied both vertically and horizontally. If youre installing a metal roof over another roof, you will need furring strips. Make sure you correctly space the furring strips to decrease the amount of condensation. Common spacing is 24 inches.

Is Underlayment Necessary For A Metal Roof

In simplest terms, yes, you should use underlayment with your metal roof. It might not be absolutely necessary, but it is highly recommended, especially because metal roofing is notorious for being cold in the winter, hot in the summer, and loud when it rains. High winds may also affect your roof. Fortunately, adding underlayment will provide an extra layer of protection for your home, and it will improve everything from insulation to waterproofing.

If you need help deciding on a type of underlayment that would work for your home, dont hesitate to ask our team at Legacy Service.

Recommended Reading: What Is The Average Cost Of New Roof

Factors To Consider When Installing A Metal Roof Over Shingles

- What we said above about installing metal over shingles is true in the majority of cases. But its always best to check with your local building and zoning departments to make sure they approve metal-over-shingle installations.

- If your shingle roof has leaks, youll need to inspect for rotting rafters or sheeting. These problems should be fixed before installing the new roof.

- If the current roofs weight has caused structural problems like buckled trusses or decking that is sagging, these issues need to be addressed before new installation begins.

- Its usually a good idea to consider adding some type of underlayment on top of the shingles to prevent their granules from contacting the metal and leading to corrosion. Your metal roofing contractor will tell you about options for this.

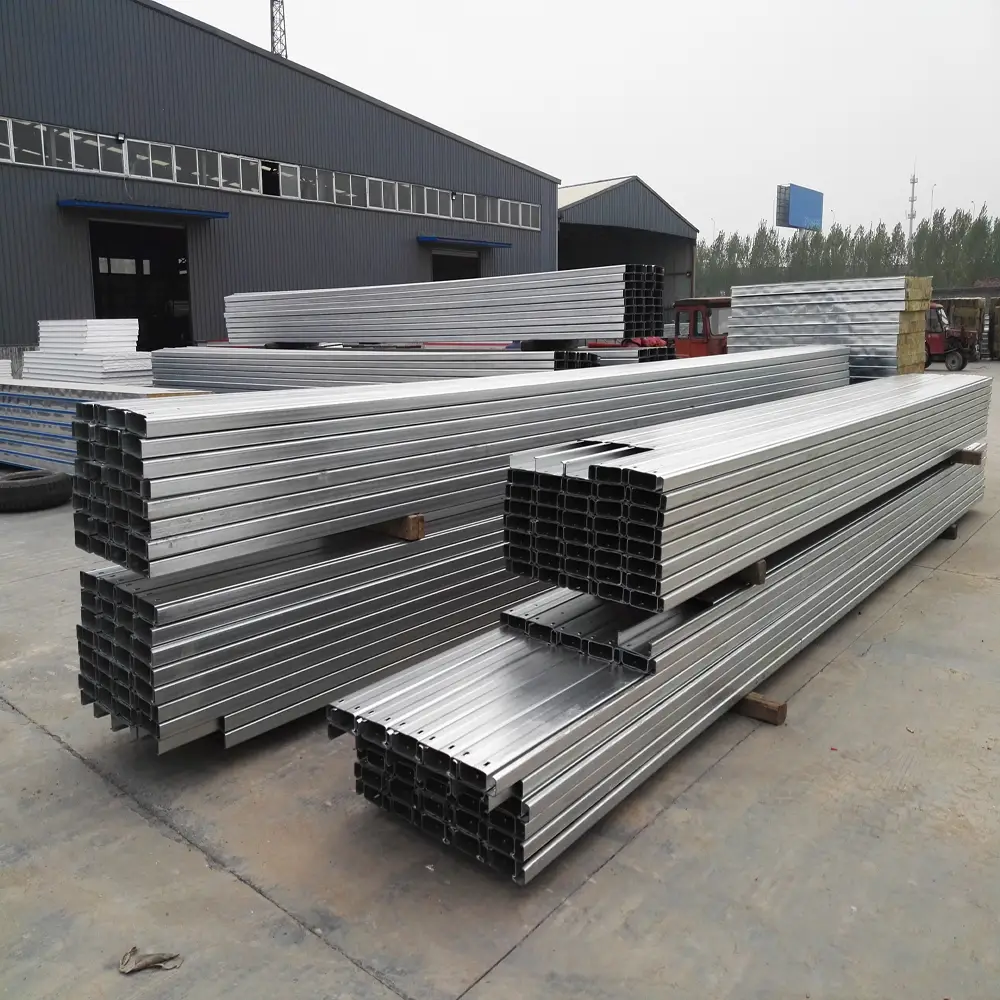

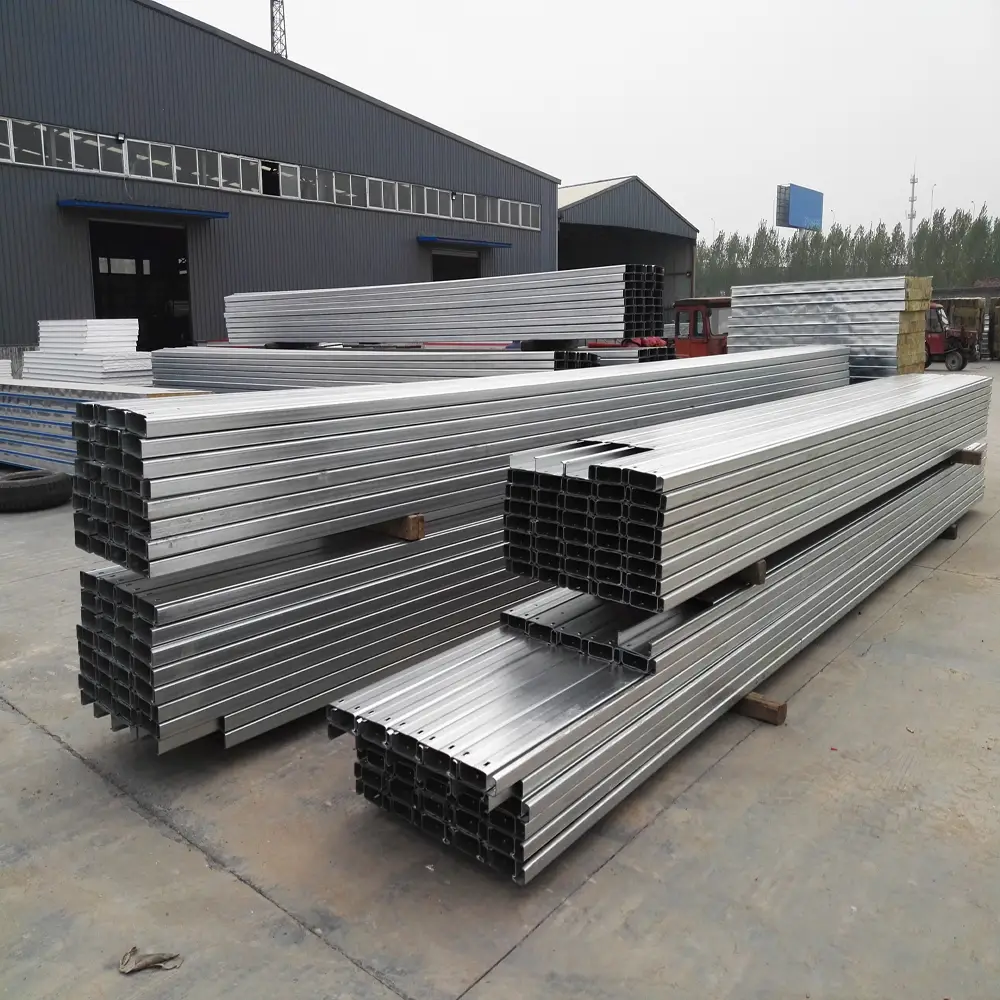

How Rhino Purlins Are Better

Some steel building companies provide purlin connections that butt flush against each other on the rafter.

However, at RHINO, we design our purlin systems for maximum strength.

The greater the amount of overlap between connecting purlins, the stronger the connection will be. Consequently, all RHINO purlins overlap by design. The amount of lapping increases as the load increases.

Moreover, RHINO rafters have factory-welded clips already installed for attaching purlins. Pre-welded clips simplify construction and speed up the framing process.

Call RHINO today at to learn more about the cost-effective RHINO Difference of low-rise construction. Our experts are standing by to take your call now to answer questions about our metal building roof purlins.

You May Like: How To Open Mini Cooper Convertible Roof Manually

Can You Put Metal Roofing Directly On Rafters

Yes, a metal roof can be installed directly over rafters. Since corrugated metal panels are relatively lightweight, they can fit almost any type of situation. You can install the roof with or without insulation, but installing rolled insulation is usually a good idea because it can help keep the inside of the building at a comfortable temperature.

Will A Metal Roof Make My House Hotter

Actually, a metal roofing system can save you money on your a/c costs because it has a higher heat reflectivity than other roofing products like asphalt/fiberglass shingles, wood, tile, ect. During the summer, metal roofs make buildings cooler by efficiently reflecting away sunlight and reducing the amount of heat transmitted into the building. Likewise, it makes buildings warmer in the winter by reflecting inside heat from the underside of the roof back into the building. This good thermal reflectivity translates into energy savings by reducing cooling costs in the summer and heating costs in the winter.

4Ever Metal Roofing is a metal roofing contractor that strives to provide permanent roofing solutions that are durable, beautiful, and affordable. We specialize in metal roofs, metal shingles, gutters, and siding.

Read Also: What Is The Longest Lasting Roof

Benefits Of Sturdy Metal Roofs

When you install your new metal roof over an existing shingle roof, you immediately save money that normally would be spent to have the old roof torn off. But this is just one of many benefits of a metal roof. Here are four more:

1. Long life: A properly installed metal roof should last for 40 or 50 years or more before a replacement is needed.

2. Virtually impervious to damage: Metal roofs hold up in the most intense weather events from pounding hail and ice storms to gale-force winds and searing summer heat.

3. Very low maintenance: Because of their strength, metal roofs wont require regular, expensive repair jobs. Year after year, decade after decade, they retain their soundness.

4. Lowered cooling bills: As noted above, special coatings on metal roofs allow them to reflect and block heat rather than absorb it. This results in cooler interior temperatures in the summer and less need to use your AC system.

If youd like to know more about metal roof installation or metal roofing in general, contact the experts, Advanced Aluminum of Lakeland, FL. We manufacture top-grade metal roofing products used by leading contractors across the Lakeland region. Reach us with questions at 648-5787.

Underlayment Vs Purlins Installation

When youre installing your new roof, its important that you dont place the metal panels directly on the asphalt shingles. The abrasive surface from your old roofing can scratch the underside of the sheet metal, which will remove the protective coating that prevents corrosion. There are two options to choose from.

You can use an underlayment to cover your old roof. You can use a water-resistant asphalt-saturated felt or a water-resistant synthetic underlayment. For areas with extreme winters or heavy rain fail, you can use waterproof rubberized asphalt. The underlayment will protect your new roof from scratching and provide a moisture barrier.

Purlins can be used to provide space between the old roofing and the new metal roofing panels. You can stall them on your old roof deck and screw your metal roofing panels to the purlins. This will provide ventilation while protecting your new roof from the abrasive shingles. It will also give you a nice, flat surface to install your panels on.

There are pros and cons to each method, and every roof installation is unique. Using purlins is the more expensive option, but its not always the best one. A roofing contractor will have the expertise and experience to make the right call for your situation.

Also Check: What Is A Timberline Roof

Can You Use Pressure Treated Wood Under Metal Roof

Yes, you can use pressure treated wood under a metal roof. The pressure treated wood will help to protect the roof from the elements and will also add an extra layer of insulation.

Is it a wise decision to put a vapor barrier over plywood to prevent condensation from getting absorbed into the plywood from the steel roof? It is common for metal roofing instructions to be incomplete and lacking important details, which can have a negative impact on the project. Condensation is a major issue with metal roofing, as you correctly point out. Metal roof companies typically recommend the use of felt paper on roof sheathing. The asphalt in felt paper adheres to the untreated wood very well, making it waterproof and protecting the wood from damage. Condensation is unlikely to pose a problem if youre simply covering the patio with sun and rain. Make sure to lay a 1/4 inch gap between the two places. Youll almost certainly want to use one long 2-by-4 as you walk up the roof. Where does condensate flow if it gets trapped in a tube?

Types Of Metal Roofing

Before we get into the steps on how to install metal roofing its important to understand what types of metal roofs exist. While metal roofing can be made from a variety of metals, tin, zinc, steel, aluminum and copper are the most widely used and most commonly available options. Each metal has its own advantages and disadvantages, as well as cost considerations. Steel, for example, is the least expensive option while copper is the most expensive.

In addition to material choices, metal roofing is also available in three design styles: through-fastened panels , modular panels and standing-seam panels.

- Through-fastened corrugated metal panels are the most common and readily available type of metal roof. They can be installed over roof sheathing or purlins.

- Modular panels, which mimic other roofing materials like asphalt shingle and tile, are also available in a wide range of colors and styles. They, too, can be installed over solid sheathing or wood battens.

- Standing-seam panels install over solid or skip sheathing and have the most complex installation process, so are typically best left to professional roofing installers.

You May Like: How To Tell When You Need A New Roof

Should You Remove Old Shingles Before Installing A Metal Roof

Metal roofs can be installed over your existing roof without tearing off shingles, provided local building codes allow it. While shingle removal is the preferred route, tear-off is messy and raises the cost of the job. If trapped between the metal roofing and old roofing, moisture can build up and cause mold and rot.

Metal Roof Purlins Spacing And Rafter Distance Details

By: Author Ryan M.

A metal roofing system is a great choice for any building that needs protection from the elements. One of the main components of this type of system is the purlins and rafters.

There are many things to consider when you choose your spacing and distance, and we will go through them in this post!

Don’t Miss: How Much Should It Cost To Replace A Roof

The Pros And Cons Of Shingle And Metal Roofing

While installing a shingle or metal roof is a personal decision, there are some general costs to keep in mind. Metal roofs can cost as much as $900 per 100 square feet, whereas shingle roofs are much more affordable at first. Furthermore, installation will be more expensive for metal because it is a specialized job. Corrugated steel panels are the most affordable type of metal roofing, with prices ranging from $3.50 to $6.50 per square foot.

What Is A Purlin In A Roof

A purlin is a horizontal bar that supports the weight of your roof decking and prevents it from being blown away by strong winds. They are commonly used in metal structures to tie rafters on the roof to enhance the stability of the building. For wood-frame buildings, the purlins may replace narrowly spaced rafters.

Purlins are essential and beneficial components when roofing. Therefore, it is good to know different types of purlins, their installation, selection, and maintenance for effective roofing.

This article explores all the necessities of purlins that will come in handy when roofing.

Jump To A Section

Don’t Miss: What Is My Rv Roof Made Of

Metal Roofing In And Near Lakeland

If you are looking for the best roofing company in and near Lakeland with experience working with metal roofs, contact Roofing Depot of FL. Our experienced roofers can do metal roof installation, repair, and inspection.

In addition to traditional residential roofing, our roofing services include installation and repair of:

- Commercial roofing

- Mobile home roofing

We offer a variety of roofing options to meet our customers needs, both aesthetic and budget:

- Shingle roofing 3-tab and architectural shingles

- Tile roofing Clay tile and concrete tile

Roofing Depot of FL is pleased to offer our valued customers roof financing options that allow homeowners to pay for their roof repair or roof installation with predictable monthly payments.

Having worked with many clients over the years, we also can assist with the roof insurance claims process if damage to a roof might be covered by homeowners insurance.

Contact us today for a free roof inspection. Roof Depot of FL Well knock your shingles off.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all comments are moderated according to our comment policy, and your email address will NOT be published. Please Do NOT use keywords in the name field. Lets have a personal and meaningful conversation.

What Is The Minimum Spacing Of Purlins

How to Install Purlins. In order for the sheets to be easily fixed to the purlins, as a rough guide they should be at least 50mm wide. When positioned, roof purlins should be spaced no further than 1.2 metres apart when using sheeting with a thickness of 0.7mm, and 1 metre when using 0.5mm sheeting.

Don’t Miss: How To Shingle A Shed Roof

Metal Roofing Installation In San Diego

Preman Roofing-Solar has serviced San Diego for over 20 years. We dont use independent contractorsall of our roofers are employees trained to safely and professionally install your roof.

We service, repair, and install both metal and shingle style roofs, and all of our estimates are guaranteed. And its not just the cost you can count on-we stick to our schedule so you always know when to expect us and exactly when you can count on the work to be completed. Contact us today for a quote on roof replacement, installation, repair, and explore our financing options. We also offer residential and commercial solar panels in San Diego if youre interested in getting solar panels for your metal roof.

How To Install Metal Roofing

Difficulty

Duration

Over 1 day

Whether you are looking to replace your existing roof or add a roof to a new building, metal roofing can be an attractive alternative to asphalt shingles. Metal roofing is strong enough to survive hurricanes, hail and wildfires. It is an extremely durable material offering a life span of 50 years or more, depending on the climate and type of metal used.

Metal roofing can also save energy in some climates thanks to its ability to reflect the suns heat. While most metal roofing styles can be installed as an advanced DIY project, metal roofing installation is complicated and can vary slightly based on the brand of panels or shingles that you select. We recommend that you install a metal roof with one or two helpers and fall protection equipment designed for roof work.

This guide will teach you about the types of metal roofing and give you step-by-step instructions on metal roofing installation for a basic corrugated through-fastened metal roof.

Don’t Miss: How To Build A Roof On A Mobile Home

Steel Building Vs Wood Building Roofing

Wood framing employs decking to tie roof trusses together and support the roof. Decking is heavy and expensive. It is also time-consuming to install, driving up labor costs.

Steel building purlins eliminate the need for oriented strand board or plywood decking. Consequently, a metal building system saves money on both building material and labor.

How To Arrange Purlins When Roofing

Generally, most roofers arrange purlins depending on the roof slope. This means they are installed horizontally if the roof slopes at a 90-degree angle.

You also want to ensure the purlins are spaced evenly to provide adequate support for the trusses. The purlins shouldnt be placed close to each other to prevent the roof from bending or the shape from being distorted.

You can achieve this by placing the purlins at the trusses nodes rather than on the members for even distribution and a straight roof.

Also Check: How Much To Put Solar Panels On Roof

The 7 Unique Components Of A Standing Seam Metal Roof

1. Frame

Purlins play a very important role in a structure by providing support to roof, stabilize and strengthen the building structure and provide additional support between the spans of individual framing bays. While installing a new roof, if the existing channels are found to be damaged, itâs recommended to get them replaced. If the roof decking is sound then it can hold your new standing seam roof.

2. Lock Strip

Lock Strips lock the standing seam metal panels to the edges of the roof and help them stay in place during rough weather conditions. They are attached to the eaves – which are the bottom edge of the roof, and rakes – that are the slanting edge of the roof. Ensure to opt for roofing systems with sturdy lock strips that prevent the roof from flapping due to strong winds.

3. Underlayment

A significant part of a metal roof, Underlayment is often a felt material that gives extra protection to the roof decking. In a standing seam roofing system, a high heat ice and water shield is used as an underlayment. Itâs suggested to install the underlayment over the lock strip of the standing seam roof.

4. Metal panels

Metal panels are connected to the roof deck with lock strips and with clips to the seams. The standing seams seen on metal panels, also known as ribs, are locked together at the seam. This lets the metal panels slide backwards and forwards with ease, allowing free expansion and contraction of the roof.

5. Clips

6. Z bar

7. Ridge capping