What Is The Correct Screw Pattern And Spacing For R

The screw placement for R-Panelis straight forward. The screws are located in the same location for both metal roofing and metal siding applications. One item of importance is that you will have additional screws at the ends of the panels. This lessens the likelihood of strong winds ripping the panels off of your building.

There will be five panel screws and one lap screw per screw line at the panel ends. The remaining interior panels will have three panel screws and one lap screw at each screw line. Pay close attention to the diagram above in which the top left is circled. This is blown up larger and shown in the diagram as detail AA. You must attach a panel screw in this exact location. In addition, there are lap screws that are connected at 12 to 18 on center and butyl tape seal, which is the same thing as mastic tape.

The screw placement for 7.2 Panel and Western Rib is simple. Panel screws are located in every panel low. There will be five panel screws and one lap screw per screw line. Lap screws are connected at 12 to 18 on center and butyl tape seal is used at the panel sidelap.

What Is The Most Cost

While metal roofing offers tremendous long-term benefits, most building owners still have a strong desire to spend the smallest amount possible to get the biggest bang for their buck. And with the plethora of places to spend money on their businesses including everything from facility infrastructure, to inventory and staffing expenses and manufacturing to marketing spend, the fight for dollars is real.

Thats probably why one of the most frequent questions we are asked involves finding the most cost effective way to put standing seam on a project.

Unfortunately, every project has different variables so its pretty dangerous to provide one absolute answer. With that said there are a few things to consider.

Trim For Corrugated Metal

If youre learning about how to screw down a metal roof then theres a good chance you will need help installing the corrugated metal trim or the corrugated metal panels. Our easy to navigate Metal Roofing Learning Center has step by step installation videos for all of your corrugated trim installation details.

Read Also: How Much Does It Cost To Install Roof Rails

Standing Seam Panel Profile Types

One of the most significant selling points of standing seam metal roofing is the variety of choices and options for customers. These choices stretch far beyond just the panels color to include the length, width, profile, shape, thickness, etc. One of these choices is the panel profile type.

A panel profile refers to the shape and way two or more panels are seamed together. Depending on what type of roof you have, how steep it is, what environment your property is in, and various other factors, it will dictate what profile you should pick with the help of a contractor or architect. Many panel profiles comprise the standing seam category, including snap-lock, mechanical seam, batten panel, and nail/fastener flange.

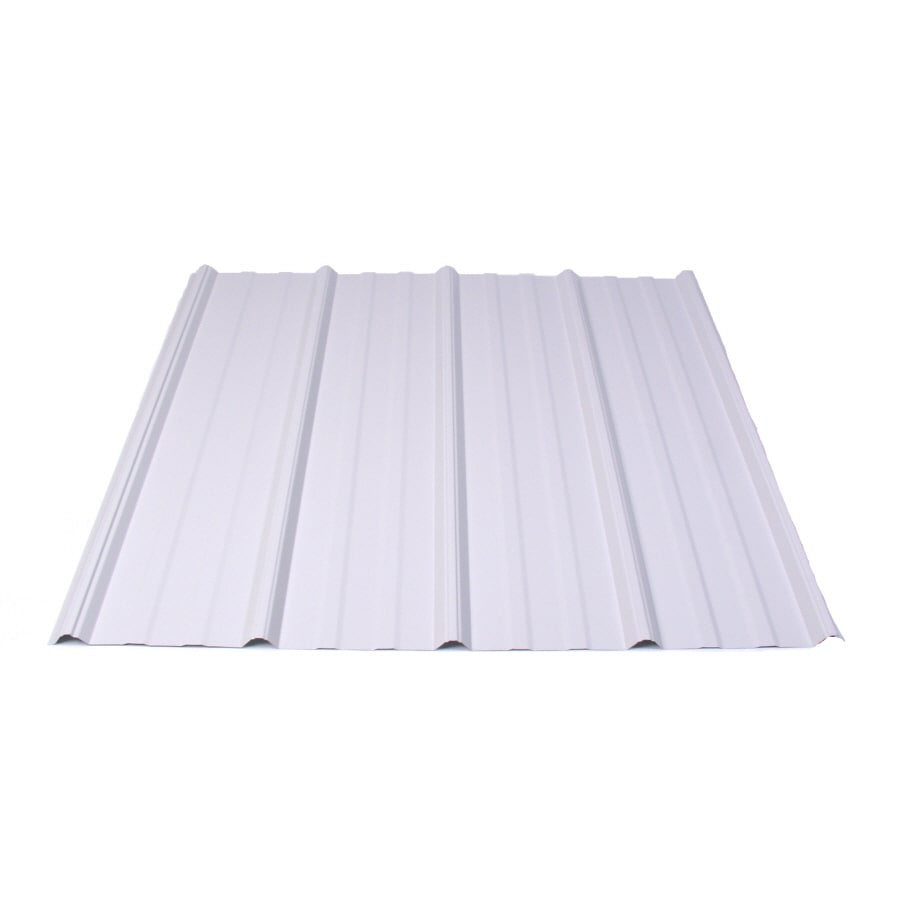

What Is R Panel Roofing Definition Alternatives Cost And Colors

Metal | Homeowner Education | Corrugated Roofing | roof

If youre searching for the right metal panel for your project, youve most likely realized there are many different options to choose from. One metal panel that does not get discussed as often as some other panels, yet provides a great value at a lower price, is R-Panel.

At Western States Metal Roofing, we have been manufacturing R-Panel, along with our other metal panels, for over 20 years. We tell our customers that we believe R-Panel is the nicest panel at the lowest price point. However, its still an exposed fastener panel which has quite a few advantages and disadvantages when compared to standing seampanels.

For more on the differences between exposed fastener and standing seam, please watch:

Perhaps you either havent heard of R-Panel before or dont know much about it. Our goal in this article is to change that by educating you on R-Panel so that you can decide if its a material to consider for your next project. We will discuss:

- What is R-Panel?

Don’t Miss: How Much Does It Cost To Fix A Roof Leak

Calculate The Number Of Metal Panels

You must be wondering now how many metal sheets do I need for my roof. You need to divide the length of one side of the roof with the width of the metal sheet. In our case, the length of the roof is 21 feet, and the Width of the panel is 26 inches or 2.1 feet.

Now divide 21 by 2.1 which comes out to 10. You will therefore require ten panels for your roof. You have a calculation for one side of your roof, so repeat the procedure to find out how many panels you need for the other side. The number should be almost identical.

In our example, the total number of panels needed is ten, and the length of each panel should be 254 inches.

Drive Screws Just Right

- Fastening the panels just right is the key to a watertight roof. Here is what you should know:

- At the eave, place screws on both sides of every rib and lined up to go through the foam closure strip.

- Each row should be spaced no more than 24 inches with one screw at each rib on the overlapping side.

- Start at the bottom, fastening across the panel in rows, working toward the ridge.

- Drive screws to seat flat on the roof a crooked screw wont seal.

- Dont over-tighten or under-tighten. Tighten just enough to compress the rubber gasket to the edge of the screw head, not past it.

- Clean up any metal shavings or burrs right away. They will rust.

You May Like: Where To Buy Roof Top Tents

What Gauge Metal Roofing Is Best For Houses

It depends on where you live, but most homes in the United States that have metal roofs use 29-gauge panels. 29-gauge panels are the thinnest, so they tend to be the cheapest for homeowners. Houses dont typically need thicker panels, so unless you live in an area that gets plenty of hailstorms throughout the year, your best bet would probably be 29-gauge.

What Is A Metal Roof Panel

Panels are a fantastic metal roofing alternative for people searching for a long-lasting and budget-friendly material. A metal roof panel is a sheet of metal that covers your homes top.

It can be made from any number of materials, including steel and aluminum. In some cases the panels are painted to give them color or protection from rusting or corrosion, but in other situations they have no coating at all! Metal roofs come with many advantages over traditional roofing materials.

For example, they are extremely durable and can last for many decades with little to no maintenance! However, metal roof panels do come in different sizes.

Read Also: What Are The Advantages And Disadvantages Of A Metal Roof

How To Install R Panel

R Panels have an exposed fastener system, meaning the fasteners penetrate the panels. Each time this occurs its a potential leak point. Also there are visible screw heads throughout the panel post-installation.

A benefit of an exposed fastener system is that the installation is generally faster and simpler compared to a concealed fastener system. As a result, the installation costs on R-Panel are usually 30% to 50% less expensive than the installation of a standing seam metal roofing.

A simpler installation also makes R-Panel a good choice for a DIY project, as less time, tools, and experience is required for installation.

What Is The Cheapest Metal Roof

Types of metal roofing: quick overview. Corrugated steel panels. The least expensive option is a corrugated steel roof, also commonly known as a tin roof. Curved metal roof, stone-coated steel tiles, did you know? Standing seam metal panels, concealed vs exposed fastener metal roof, metal shingles, and zinc and copper roofing are a couple more things to keep in mind.

Recommended Reading: Where Do The Screws Go On A Metal Roof

What Exactly Is Corrugated And Ribbed Metal Paneling

Sheet metal coil gets fed into a roll-forming machine that shapes the metal sheet into the curvy U-shaped, wavy pattern the primary variation for corrugated metal roof and wall panels.

Corrugation gives metal panels considerable structural strength, which makes it possible to use these otherwise thin sheet metal panels for building envelope applications, such as roofing and cladding.

Check out the video below to see how its made:

Old School Corrugated Steel Panels

During the height of the Industrial Age, steel became relatively cheap and abundant. Metal was viewed as the kind of material that offers an economically viable way to cover the roofs on large agricultural and industrial buildings. Back then, the corrugated steel panels were often non-coated, but that was not a problem since there were plenty of spare steel roofing and wall panels to replace any corroded ones as needed.

As steel corrodes, it develops visible rust. When the old steel panels would get too unsightly or worse yet, develop holes resulting in leaks, they would get replaced with the shiny new pieces.

Today, corrugated metal panels are often chosen because of their old school appearance and relatively low cost compared to standing seam and architectural metal shingles and tiles.

G-60 vs. G-90 Galvanized Steel Panels and their Paint Finishes

Corrugated Metal Panels vs. Crimped or Ribbed Metal Roofs

Metal Roofing Colors For R Panel

R Panel is offered in more color options than most metal panels. This is because its also offered in multiple paint finishes. In fact at Western States Metal Roofing, we offer R-Panel in over 100 unique specialty paint prints and colors in both paint finishes. You will find the panels in both the premium PVDF or the more affordable SMP paint.

If you need help choosing a metal roofing color the article below has tons of great tips and suggestions that will make it easy to pick the perfect metal roofing color.

Keep in mind though that the main reason most people use R Panel is for the cost savings. The best bang for your buck is an SMP paint finish in a 26 gauge thickness. PVDF paint is only available in 24 gauge material and this will increase the cost by 50% when compared to SMP/26GA.

Its critically important to understand the key differences between both paint systems. In some instances a 26 gauge SMP paint is the correct product, but in other cases the product should be heavier gauge PVDF. We suggest that you read:

Also Check: What Size Dumpster For Roof Shingles

Which Is Better: Steel Or Aluminum Roofing

Neither type is better than the other its all about your preferences. However, if youre trying to choose between steel and aluminum roofing, do as much research as possible before you make your decision. In the previous sections, you can read about the pros, cons, and costs compared to the other types.

To make the most informed decision, contact your local roofing experts to schedule a consultation. Our team at Legacy Service will guide you throughout the process, from helping you determine the best choice during the inital consultation to communicating with you every step of the way if you decide to go through with the project.

Also Check: How Do You Know If Your Roof Is Leaking

What Sizes Does Metal Roof Come In

The most common gauges for metal roofing are 29, 26, 24, and 22 gauge.

What is the spacing for metal roofing?

For heavier material such as gage steel, the metal roof purlins spacing length could go up to 4 feet. The typical spacing standards for residential and commercial buildings are about 1 to 2 feet. The support system for the roof is comprised of ridgepole and rafters or purlins.

Also Check: Should I Install Solar Panels On My Roof

Corrugated Roofing Sheets: Dimensions And Size

Corrugated sheeting is a popular choice for both domestic homes and industrial/agricultural applications due to its design. The âwavyâ design of the corrugated metal sheets provides efficient water run-off to reduce water pooling on top of the corrugated sheets in wet climates, helping to minimise maintenance and keep your roof cost-effective. They are also a popular choice for cladding the side of your build.

The recommended length for corrugated sheets is up to 6 metres. This is when choosing the corrugated metal thickness of 0.7mm. If youâre planning to use the roofing materials for steel cladding, then sheet length runs go up to a maximum of 5 metres. For wall cladding applications, it is recommended to use a sheet gauge of 0.5mm for corrugated roof sheets.

The width of Corrugated roof sheets provides 990mm horizontal coverage when lapped by one corrugation, which is the desired amount for corrugated roofing sheets. Bear this in mind when measuring and ordering roofing sheets, as this will affect the number of runs youâll need to secure.

Benefits Of Standing Seam Metal Roofing

Compared to other panel profiles, a standing seam metal roof has quite a few benefits. Here are just a few:

- Aesthetics: The sleek lines and crisp, seamless look of the panels make them highly attractive to anyone looking for high-end or modern looking finished roof.

- High-Performance: Standing Seam panels are typically tested heavily against extreme weather conditions, like high-speed winds or heavy hail, and come out performing wonderfully.

- Fastener System: The hidden fastener system used in Standing Seam metal roofing eliminates most issues related to faulty, improperly installed, or rusting fasteners, which can occur with exposed fastener systems.

- Longevity: Like the majority of metal roofing options, Standing Seam roofs have an average lifetime of 40-70 years, compared to other materials like shingles, which typically only last between 10-20 years.

- Durability: Just like other metal roofs, Standing Seams durability is a huge advantage it stands up extremely well in all different types of environments with ease.

Read Also: Can You Mount Solar Panels On A Metal Roof

Read Also: What Are The Different Types Of Roof Shingles

What Size Are Metal Roof Panels

Metal roofing has gained incredible popularity in the lastfew years. Because of green construction and the need for sustainability inincreasing hostile climates, new and used metal roofing has become the toptrending 21st century roofing choice. More durable and versatilethan traditional asphalt roofing, metal roofs save energy and offer superiorprotection. When choosing metal roofing, one aspect to consider is size. Whatsize do you need for your project?

Snap A Square Reference Line

- A square reference line is important for installing roofing panels evenly. Use the 3-4-5 method to establish a reference line 90 degrees to the eave.

- First, make a mark along the eave three feet from the corner. At that mark, measure four feet toward the ridge. Then, from the original corner, measure five feet and mark where it intersects the second mark.

- Snap a line from the first three-foot mark through the intersection of the second and third marks. Since the Getaway roof is larger, I measured to 21 feet, 28 feet and 35 feet to make my square reference line.

You May Like: How Much Does A Roof Cost In Houston

Standing Seam And Corrugated Metal Roof

Standing seam metal roofs have been used predominantly on commercial buildings for many years, but recently they have gained popularity as a hip roof replacement system for residential homes.

Standing seam installations are covered by ASTM Specification A730/A730M for Installation of Metal Roof Deck, G90.7.31 Standard Practices for Installation of Standing Seam Metal Roof Systems, and G90.7.32 Standard Practices for Installation of Corrugated Metal Roof Panels.

Since 1938 the standing seam roof has been a staple on commercial buildings because of its durable nature, lasting 50 years or more with little or no maintenance needed to repair leaks.

Due to its simplicity and durability the standing seam roof has been used all over the world and is one of the most accepted metal roofs.

Corrugated metal sheets are commonly used on commercial buildings such as warehouses, big-box stores and car dealerships where aesthetics are not a high priority because corrugated panels add strength and give this type of structure its big rig appearance.

In recent years, corrugated metal roofing has been gaining acceptance as a residential roofing material because it is more affordable, environmentally friendly and has a more appealing look than other types of exterior cladding materials such as asphalt shingles or wood shakes.

Also Check: Roofing Costs In California

How Wide Is A Piece Of Metal Roofing

Metal roofing comes in 24 and 36-inch wide measurements. However, each of these widths also provides for 2-inch overlap on both sides. You can purchase metal roofing material in any length you need and have it cut to the appropriate length before you install it.

Similarly, you may ask, what is the standard width of metal roofing?

The two most common widths are 26 and 36 inches. Other standard widths include 24 and 39 inches. When calculating coverage using the width and length of corrugated roofing, keep in mind that each piece will need to overlap by several inches.

what is the width of corrugated iron? 850mm

Furthermore, how do you measure for metal roofing?

Divide the length of your roof by the width of the metal. In our example we will use 24-inch standing seam roofing, so we will divide 360 inches by 24, which equals 15. This is the number of metal panels needed for one side of the roof.

How wide is colorbond roofing?

762mm is the cover width which allows for 1.5 rib overlap. The actual single sheet width of the corrugated sheet is 850mm wide.

You May Like: Can You Use Flex Seal On Camper Roof