Metal Roofing Components Definitions

- Accessories Accessories are the additional components needed to complete a metal roof installation. This includes fasteners, clips, underlayment, sealant, pipe boots, and anything else beyond the metal panels that make up a roofing system.

- Metal coils & sheets Metal coils are long, continuous metal rolls that have been treated and/or coated with a paint system. All metal roofing starts out as coil, which is then rolled out, processed , and then rollformed into panels for installation.

- Panels Panels are rollformed pieces of a metal coil that have been shaped into the desired profile/ribbing structure and are ready to be connected or seamed together to form a metal roof.

- Profile The shape that the metal panels are formed into. The profiles are what determine how the panels fit, connect together, and are attached to the structure.

- Rollforming machinery/equipment The machinery, either in-plant or portable, that forms and shapes the coil into individual panels.

- Seam The side rib at which two metal panels come together and are connected. Seams are formed using a rollformer and are then snapped or mechanically seamed together.

Stone Coated Metal Roofing

A metal slate roof gives you the look and feel of a natural stone roof without the high price tag

-

Lighter weight than natural stone

-

Lower installation cost

Average Cost per sq. ft:

$5 – $12

Stone coated metal roof types allow for aesthetic diversity by offering the benefits of metal roofing with the look of more traditional clay or slate shingles at a fraction of the cost. Stone coated metal roofing is lightweight, durable and will offer a long lasting roofing option.

Stone coated steel roofing costs can range from $5 to $12 per square foot of roofing material. The total cost for installation on a standard 3,000 square foot roof would average to be around $24,000.

Metal Material Types: How To Choose The Best Material For Your Roof

Whether youre a contractor, installer, architect, distributor, or building owner, knowing the pros and cons of the most popular metal roofing materials can help you make the best choice for a structures roofing project.

Whether youre in the market to purchase a new metal roof, a distributor trying to sell metal coils or sheets to customers, or a contractor dealing directly with a home or business owner, its vital to know the pros and cons of different metal roofing materials.

Five of the most common materials used in metal roofing are Galvalume®, aluminum, zinc, copper, and stainless steel. Luckily, there isnt just one solution for every single customer, so the advantages and disadvantages of each metal should be discussed in depth with the contractor, distributor, architect, or manufacturer before making a final decision.

As one of the leading distributors of coated and bare metal products in the industry, Sheffield Metals helps individuals find the solution that will work best for their specific residence, building or business every day.

You May Like: How To Patch A Leaking Shingle Roof

Also Check: How Much Is A Roofing Permit

Cons Of Stainless Steel Roofing

No substrate warranty One of the significant drawbacks to stainless steel is that it doesnt carry a substrate warranty. Remember that a stainless steel roof may perform well if handled and installed correctly, but it doesnt come with that additional guarantee in the form of a substrate warranty.

Expensive The cost of stainless steel is in line with the price of zinc and copper, making it a high-end metal roofing choice. Stainless steel roofing can cost anywhere from $500 to $1,300 per roofing square , depending on the finish, panel type, and thickness.

Expansion and contraction concerns In climates with striking temperature differences, stainless steel roofing systems expand and contract during heating and cooling cycles . Your contractor should ensure that your system can accommodate this thermal movement.

Not recommended where there is standing water Roofing made with stainless steel, especially if its in contact with other non-stainless steel metals, requires adequate draining methods to remain durable and functional. Too much standing water on stainless steel can act as an electrolyte and cause galvanic corrosion.

Tin Roofing Pros & Cons

Tin Roofing is an often-requested item by enthusiasts around the United States and Canada. The term “tin roofing” is used interchangeably with metal roofing, steel roofing, or galvanized steel. In fact, tin is actually a rarely used type of metal for roofing. Tin itself is an element, like Copper or Zinc. Tin was introduced as a canning material, which was then adapted by rural DIYers who flattened out the material and used it as a shingle when other materials were not available.

When Aluminum became the standard for containers, which replaced tin roof sheets, so went the use of it as a DIY building material. In reality, when you hear reference of “tin roofing” in modern times, this is normally referring to either a galvanized steel or aluminum material rather than actual tin roof sheets.

For its DIY use in the 19th century, and its ability to remain a part of our vernacular long after it left, Tin Roofing could be fondly considered the Willys Jeep of roofing. While it still has many uses in science and technology, Tin is no longer generally used as a building material option and tin roof sheets have been virtually phased out.

Don’t Miss: How Do I Pick A Good Roofer

Common Metal Roofing Materials

Metal roofing is typically made from recycled and recyclable materials. This makes metal roofing a sustainable option in addition to being extremely durable and long-lasting. You can feel good about choosing a metal roof, knowing youve made an environmentally-friendly choice thats worth the cost.

Here are a few of the most common types of metal roofing materials and their pros and cons.

How To Find The Right Contractor

A quality job depends on hiring a pro who specializes in the style of metal roofing youre after. You can start with an online product search, and then work directly with the manufacturer to find a qualified contractor in your area. Or visit the Metal Roofing Alliances website to connect with local pros and to view their websites for examples of their work.

Tip: Look for a roofer who will offer a warranty that covers labor in case of a leak for at least five years after installation. If a metal roof doesnt leak in that time, theres little chance of it leaking afterward.

You May Like: What Is Average Cost For Roof Replacement

How Roofing Companies Process Metal Roofing Panels

Roofing companies get the thick coils of steel from the mine. Afterward, they reduce them to the necessary thickness for roofing generally between 22 gauges and 28 gauges. They will pass through four phases to be galvanized and painted. These phases are the following:

What To Look For In Steel Roofing

A high-quality steel roof can meet the needs of homeowners who have a modest budget and realistic expectations of the roofs functional and cosmetic life.

- Experienced Installer: Choose a reputable, experienced steel roofing installer. Although highly durable once installed, steel roofing must be handled with care during installation to avoid dents and scratches.

- Galvanized Steel: Go with Galvanized steel roofing products, not galvalume. Galvanized steel offers more protection from rust than cheaper galvalume products

- Warranty: Read your warranty carefully! Many 50-year steel roofing warranties do not actually cover rust formation where steel has been exposed during the installation process. Learn more about metal roofing warranties.

Dont Miss: How Much Flat Roof Cost

Read Also: What Are The Best Shingles To Put On A Roof

Exposed Fastener Metal Roofing

The exposed fastener types of metal roofing are the most popular types because they offer a nice, clean look even with visible screws. And, best of all they arent as expensive as hidden fastener roofing. Now, the big downside that youll notice with this type is that its not as resistant to aging and can break down over time, especially around the exposed fasteners.

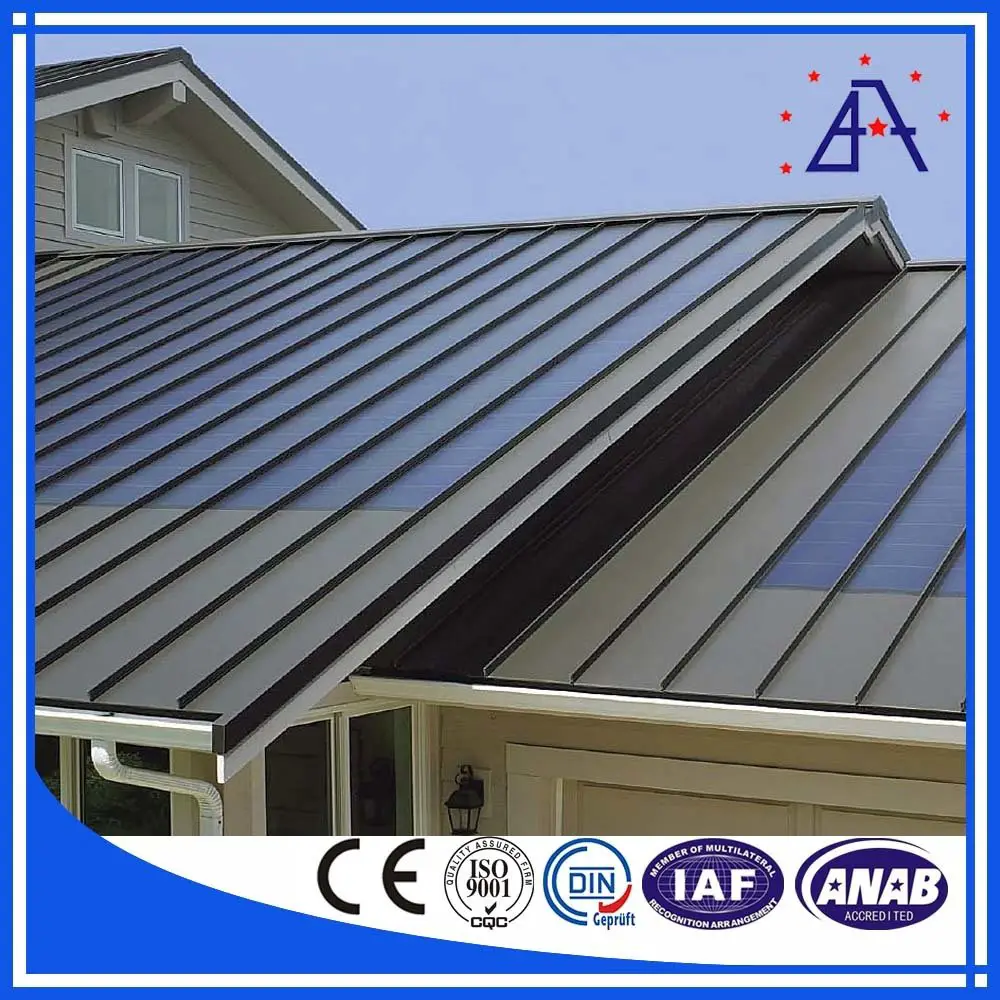

What Materials Make Up A Standing Seam Metal Roof System

Are you ready for a roof replacement? Are you thinking about getting a metal roof over the widely used asphalt? If so, youre probably looking at getting a standing seam metal roof system.

But what is a standing seam roof, and what are the roofing materials that make it up? Luckily, were here to give you a breakdown.

The team at Bill Ragan Roofing has installed metal roof systems in the Nashville area since 1990. Our workmanship ensures you get the maximum life out of your new metal roof investment. Thats why we offer a lifetime warranty.

So, what are the materials that make up a standing seam roof? Always eager to educate on the art of roofing, Im going to answer that question.

Continue reading to learn what a standing seam roof is and the 7 materials that make it up.

Don’t Miss: How Much Do Roofing Company Owners Make

What Are The Different Types Of Metal Roofing Materials

Wood Shingles And Shake

The go-to roofing choice for hundreds of years, many homeowners love the look of wood shingles and shakes and how they weather to an attractive shade of gray. Wood shakes are handmade and rougher-looking than wood shingles, which are usually cut by machine.

If you live in a fire-prone area, look for Class A fire-rated wood roofing products that include shingles treated with a fire-resistant coating.

Pros: Wood shingles offer a rustic look and are a natural product usually made from cedar, redwood and southern pine.

Cons: Fire codes in some areas prohibit use. Wood shingles can be a concern in wet climates, and can mold, split or rot.

House Styles: Shakes rustic aesthetic pairs well with bungalow, Cape Cod, cottage, Craftsman and Tudor-style homes.

Cost and Life Span: Prices start at around $100 to $150 a square and will last around 25 to 30 years.

Read Also: Can You Get A New Roof In The Winter

How Is A Standing Seam Metal Roof Installed

Now you know what a standing seam metal roof is and the 7 materials that make up this roof system. Knowing these materials gives you a better understanding of the individual components coming together to give you a new metal roof.

The day these materials are installed is the most important day in the life of your roof. That’s why it’s important to know what the installation process will look like.

To help you further understand your standing seam metal roof replacement, we broke it down for you.

The team at Bill Ragan Roofing has provided high-quality metal roof replacements since 1990. Our workmanship ensures your new standing seam metal roof lasts for decades. When you work with us, youll never worry about your roof again.

Check out this article on How is Your Standing Seam Metal Roof Installed? to learn what happens on the day of your metal roof replacement.

Stainless Steel Metal Roofing

Stainless steel is an iron alloy made up of at least 10.5% chromium and contains other elements and metals/materials to obtain desired properties.

When people think of stainless steel, they often think of large architectural structures such as elevators, bridges, building columns, handrails, etc. Or perhaps their kitchen appliances, cutlery, cookware, or beyond.

However, stainless steel is also an option in the metal roofing industry primarily because this material is known for its strength which makes it a high-end specialty metal that could be the right material choice for some projects.

Recommended Reading: A To Z Roofing St Augustine Fl

Pros Of Copper Roofing

Lightweight Compared to different metal substances and other roofing materials such as shingles, concrete, or tiles, copper is extremely lightweight. Not only does this make it easier for installers and contractors to work with, but it also puts less stress on the structure of a home over time.

Durability Copper is a durable element and can withstand numerous decades as a roof. If properly installed, copper roofing can last 100+ years in some instances. Copper also works well in locations with heavy snow, frequent rainfall, and strong winds.

Aesthetically pleasing Copper is often referred to as a premium roofing material, as it enriches the outside of a building and adds a metallic reddish-orange/brown focal point to a structure. As the copper ages, it develops a blue-green covering called patina, which happens because of oxidation and sun exposure. Many building owners specifically buy copper because of how it ages and adds to the curb appeal of a structure over time.

Highly recyclable Though not as recyclable as zinc, copper can be recycled and reused if still in good condition. Copper is also a naturally sourced metal and can be used in its original mined metallic form.

Solderable Copper can be soldered, unlike other roofing materials. This means roof/wall flashings and gutter joints can be weather-tight with a soldered connection.

Standing Seam Profile Options

Snap-lock Metal roofing panels that have been carefully rollformed with specific panel profile edges that snap together and require no hand or mechanical seaming during installation. Snap-lock seams tend to be a little more popular in the roofing industry because they are engineered to defend against the elements while making installation a little easier on the contractor.

Mechanical seam Mechanically seamed panels are also rollformed with specific edges that line up with each other on the roof. Once the two edges are put together, a hand or robotic seamer is used to bend the edges and lock the panels together. The locked seam resembles the shape of a paper clip. There are two kinds of mechanical seaming:

- Single lock / 90-degree seam one fold of the seam

- Double lock / 180-degree seam two folds of the seam

Tee panel A type of standing seam where the two panels come together and are connected at the top by a cap, which is then mechanically seamed in place to lock the panels together. Once the seaming is complete, the top of the standing seam is in the shape of a T.

Nail/fastener flange Nail flange is similar to a snap-lock panel system, but instead of using a clip to attach the panel to the roof deck, its directly fastened down to the deck through the male leg of the metal panel. Once the fasteners are in place, the female leg of the panel snaps over the entirety of the male leg, which hides the fastener head.

Read Also: Does Insurance Cover Roof Damage

Choosing Which Metal And Style Fit You Best

Your geography, neighborhood association, and budget will take a major role in your choice of style. In the grand scheme of things your personal taste will dictate this decision the most. While I have given you a brief introduction to metal roofing materials and styles, it will be important for you to connect with a local expert in metal roof repairs in Indianapolis to learn more about your options.

Table Of Content

Breakdown Of Costs By The Material Type And Installation Expenses

Heres the raw data on the cost of each type of roof for the material and installation. In most, there is a range of costs because both materials and installers are available in good/better/best options. You get what you pay for!

All costs below are listed on a per sq.ft. basis:

| Material Cost |

|---|

Also Check: What Is The Best Roof Coating

Also Check: How To Find Out If A Roofing Company Is Licensed

Different Types Of Metal Roofs

Galvanized steel and corrugated galvanized iron are some of the popular materials used for metal roofing. Stainless steel is also preferred by users for its stain-free quality.

Aluminum roofs are also used for metal roofing, because of its lightweight and corrosion-resistant nature. Copper and stone-coated steel are also used as metal roof materials.

Copper roofs are popular among consumers for their durability.

Copper Roofing Pros & Cons

Considered to be the grandfather of metal roofing, copper roofs have been used for centuries around the world. Copper is an extremely long-lasting metal that in ideal environments, can last well over 200+ years. Copper roofs are 100% recyclable too, making them wonderful green roof options.

Copper is an extremely soft metal, which makes it among the quietest types of metal roofing. However, with modern installation practices, all metal roofing now recommends proper substrates and insulation that minimize noise from rain or hail at the same level. The softer nature of Copper Roofing also means that in hail prone regions, it may be easily damaged. As a softer metal, hailstones will easily dent the copper. While this lowers the aesthetic value, it also performs better than a harder metal that, with a large enough hailstone, will puncture rather than simply dent the roof.

If metal roofs are the SUVs of roofing, copper roofs are the Range Rovers of their class. This brings up an apparent downside to copper. Like the Range Rover, it is extremely expensive and depending on your needs, may be more than you need to get the job done. Another negative aspect of copper is its tendency to expand and contract with swings in temperatures. While this can be controlled with the proper panel or shingle, it does need to carefully be considered when choosing this metal.

You May Like: How To Replace Roof With Solar Panels