What Causes A Chimney Leak

After reading this article, you now know what goes around your chimney. Both roof flashing and crickets are crucial to preventing water from getting into your chimney and leaking into your home.

Remember, problems with the roof flashing can lead to a chimney leak. However, thats not the only reason a chimney could be leaking.

To help you understand whats causing your chimney leak, we wrote another article breaking down the common chimney leaks and who you should call when you notice one.

Bill Ragan Roofing has proudly helped homeowners in the Nashville area with their chimney and roofing problems since 1990. Whether you need repairs or a full roof replacement, you can count on our workmanship and attention to detail to give you a roof that lasts for decades. To back that statement up, we provide a lifetime warranty on our work.

Install The Chimney Saddle

Slide the prebent and soldered chimney saddle into place behind the chimney. Nail it to the roof along the top edge. Space 1-in. galvanized roofing nails about every 6 in. along the edges or closer if necessary to flatten the metal.

Seal the sides of the chimney with prebent pieces of step flashing under each course of shingles . Slightly flatten the step flashing before you nail it in to ensure a tighter, spring-tensioned fit against the chimney. Pay close attention to overlapping each piece of flashing onto the preceding one in such a way that water is diverted over the top of the shingles. This is the key to a successful flashing job.

Complete the base flashing by nailing the saddle to the roof and sealing it with additional strips of membrane . Shingle over the portion of the saddle that rests on the roof and cut the shingles neatly along the valley, leaving about 2 in. of metal exposed.

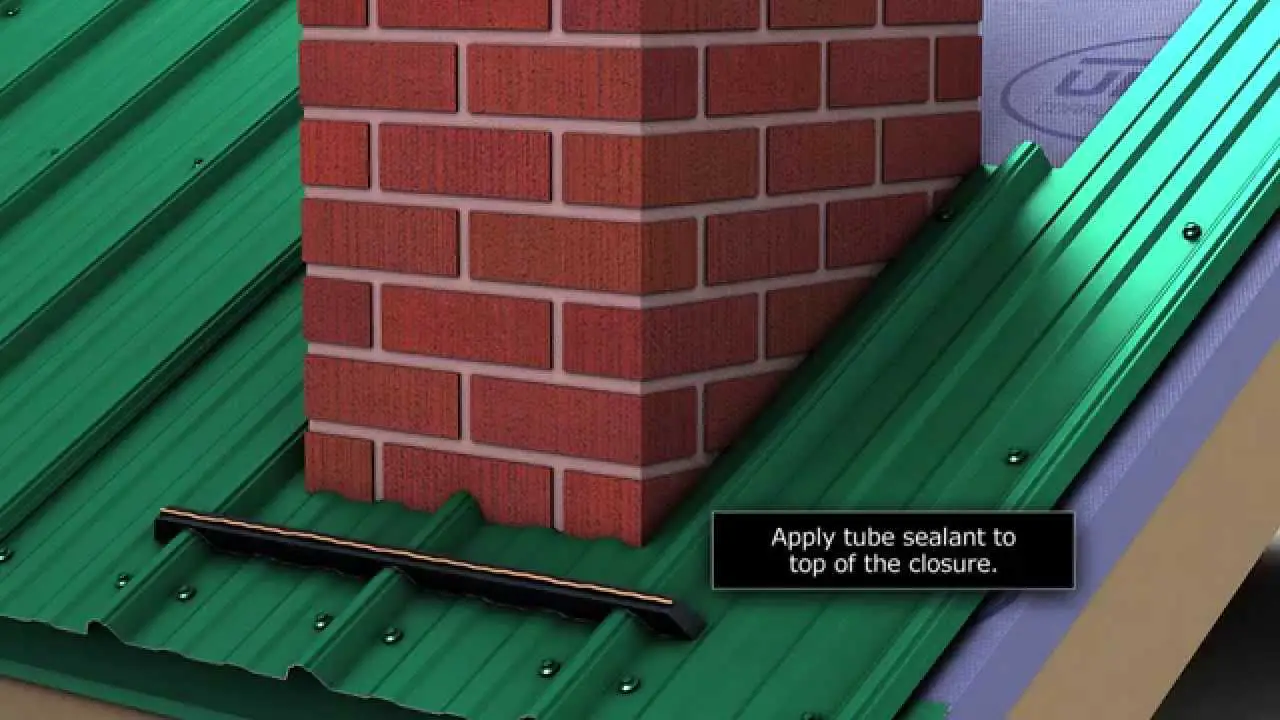

How To Flash A Chimney On A Corrugated Metal Roof

How To Flash A Chimney On A Corrugated Metal Roof. Ad browse our selection of solar sky lights. I have to flash a chimney where it penetrates a corrugated metal roof with ridges 8 inches o.c.

In this video you will be introduced to the best metal roofing flashing detail for chimneys, curbs, hvac units, and skylights you have ever seen. The local stove shop sells a part for this at $200. Chimney boot for metal roof, metal plastic asphalt shingle roof repair roof and look at the chimney pipe not need any roofing fasteners accessories and pipes on your roof repair roof jointsdue to seal it was.

Source: murida.muscglamorganandgwent.com

How to flash a chimney on a corrugated metal roof. Create an outline for the place to install the new flashing.

Source: www.jlconline.com

I have to flash a chimney where it penetrates a corrugated metal roof with ridges 8 inches o.c. Available in galvalume and stainless steel and in a variety of pitches.

Source: www.youtube.com

The local stove shop sells a part for this at $200. Bring the roofing as close to the chimney and caulk the heck out of it .

Source: www.youtube.com

Their typical stove installation costs $750.yup. Create an outline for the place to install the new flashing.

Source: www.youtube.com

If you see sealant, it means the metal isnt the first thing water, uv, or other damaging elements will touch. You can either use prefabricated flashing in these areas, or you can use a sheet metal brake to make your own.

You May Like: How Much Is A New Roof In California

Tips For Installing Chimney Flashing On A Metal Roof

- Written by on Jan 03, 2011To ensure our content is always up-to-date with current information, best practices, and professional advice, articles are routinely reviewed by industry experts with years of hands-on experience.Reviewed by

- 1-100

Installing chimney flashing on a metal roofis a laborious business but if you love to work with your hands and you want to save some money on professional fees, you may want to try doing this carpentry job on your own. To help you install chimney flashing on a metal roof, here are some tips for you.

Prevent Bubbles on the Caulking

Before you attempt to install a new chimney flashing on your metal roof, you need to clean up the area where you want to install the flashing and make sure that it is smooth and dry. This way, it will be easier for you to install your chimney flashing and prevent possible bubbles on your caulking. Bubbles in the caulking can weaken your flashing so rainwater may find its way into your chimney and cause problems so make sure that you take precautions to prevent this from happening.

Pay Attention to the Overlaps

If you install a number of flashing segments, you need to overlap these segments at about 4 to 6 inches from the previous sheet to prevent gaps. Use metal screws or nails to hold the overlaps together then apply caulking material on the seams to seal them off. If you use nails to hold the overlaps, you should use a nail gun instead of a hammer to drive the nails into the flashing.

Gather All Materials First Then Remove Old Flashing

Pry, chisel and scrape off old metal flashings and roofing cement.

Before you do anything, get your ladder, roof brackets and safety harness set up so you can work safely and efficiently on the roof. Then measure the chimney and order the saddle and flashing parts .

We ordered all our 26-gauge galvanized metal flashing bent to the correct angles and dimensions from a sheet metal shop specializing in roofing. The shop did a great job. I dropped off the dimensions and three days later the stuff was ready to pick up. Even with the custom-made saddle, the flashing was inexpensive. In addition to the flashing and shingles, buy a roll of self-adhering roofing membrane , two tubes of polyurethane caulk, and a package of 25 drive-in expanding anchors from a home center or roofing store.

Besides basic hand tools like a hammer, tape measure, 2-ft. level and square, you’ll need a few special tools for working with sheet metal and cutting and drilling masonry. Buy a good pair of straight-cutting tin snips, a 3/16-in. masonry bit and a grinder or a circular saw fitted with a drycut diamond blade for grooving the mortar .

Don’t forget safety equipment. You’ll need a sturdy extension ladder to get on the roof, and roof brackets and top-quality 2×10 planks to work safely once you get there. For maximum safety, especially if the roof is steep or high, buy a personal fall arrest system consisting of a safety harness, lanyard, rope-grab, rope and roof anchor.

You May Like: Roof Cost California

What Should A Roof Cricket Cost

You should not attempt DIY roofing, including a cricket installation. Simply purchase a roof cricket through the professional roofer youve chosen to install it. Most home improvement stores will not carry the wooden skeleton of a roof saddle as most roofers simply make it custom for their clients.

The cost of your roof cricket installation will vary depending on your location. Expect to pay at least $100 for the chimney cricket itself, and more for its flashing or shingles. Then you must factor in extra cost for the roofers time.

Typically, the cost of a roof cricket will be included in the overall cost of re-flashing the chimney, which can vary widely depending on what your chimney needs, its size, and the flashing materials. While installing steel flashing may only cost a few hundred dollars, copper flashing will be much more expensive.

Necessary Tools To Seal A Metal Roof Around A Chimney

It will be easier to seal if all the necessary tools are gathered before starting the process. Necessary tools to seal. The required tools are as follows:

- A hammer

- Pair of straight-cutting tin snips

- A grinder or a circular saw

- 6-gauge galvanized metal flashing bent to the correct angles and dimensions

- A roll of self-adhering roofing membrane

- Two tubes of polyurethane caulk

- Nails

Read Also: Skylights In Metal Roofing

What Type Of Metal Is Best

The standard construction method uses sheet metal. Standard galvanized steel is inexpensive and easy to work with.

Zincalume steel or aluminum are alternatives to standard galvanized steel.

These products offer the benefit of corrosion resistance, which is important in coastal areas where humidity is high.

When choosing your sheet metal, be sure that it comes pre-painted with a baked-on enamel paint. This type of coating will last longer than plain surfaces and resist rust longer.

Avoid steel that is painted on only one side or that doesnt have an enamel coating.

Certain types of steel are not recommended for stovepipe applications because they are combustible, conduct heat poorly or are easily damaged by rust.

Be sure to check the metals material safety data sheet before use.

Install Front Base Flashing

Snug this bent end against one side of the chimney front. Mark the edge of the chimney on the opposite end and snip and bend this end. Pound four evenly spaced 1-in. galvanized roofing nails through the front edge of the flashing to hold it in place.

Once you complete the tearout and clean up, shingle up to the bottom of the chimney and seal around it with 12-in. wide strips of ice-and-water barrier. Lap the strips 4 in. up onto the bricks and overlap adjacent strips to shed water. Run a full 36-in.wide strip across the top of the chimney. Stick this piece to the roof boards and up 8 in. onto the back of the chimney. Later you’ll seal the new metal saddle to this piece with additional strips of the membrane and then install roofing paper and shingles over the metal saddle.

Start the flashing job by installing the first piece of base flashing across the bottom of the chimney and over the top of the shingles .

Also Check: Adding Eaves To Gable End

How To Buy Chimney Flashing

Making sharp, straight bends in sheet metal is tricky unless you have access to a tool called a sheet metal bending brake. Even then, you need experience to bend complicated shapes. That’s why we’re recommending that you order your chimney flashing from a sheet metal fabricating shop. Large roofing companies often have their own sheet metal shops and are the best place to buy the chimney saddle and flashing they’ll know exactly what you need. Otherwise, check the Yellow Pages under Sheet Metal. We used 26-gauge galvanized sheet steel for our flashing and saddle, but prefinished steel or copper are other possibilities.

Most chimneys have a small rooflike structure behind them, called saddle , that diverts snow and water to both sides of the chimney. Whether your chimney has a wooden saddle covered with shingles, a sheet metal saddle or no saddle at all , we recommend installing a new custom-made sheet metal saddle .

Custom-made saddles are soldered together at critical spots that are hard to seal on saddles that are built in place. Soldered sheet metal saddles less than 3 ft. wide are self-supporting and easier to install if you just tear out any existing metal or wood saddle. Most old saddles were built right over the top of the roof boards and need no patching. Otherwise, fill in the missing boards before installing the new saddle. Saddles wider than 3 ft. may need additional support. Ask your sheet metal fabricator for advice.

How To Install Step Flashing With A Wall Corner

If a wall corner is on the rooftop, you will need to create a corner flashing piece using a typical step flashing piece. These instructions will tell you how to create a corner piece and how to install step flashing generally:

- Step One: Install your underlayment completely and your shingles up to where the wall begins, so that the first piece of flashing, or the corner flashing, will rest on a shingle.

- Step Two: To make corner flashing, take your tin snips and cut a 45-degree line from an outside corner to the center fold. Then, cut along the center fold and remove the resulting triangle. This will allow you to bend the step flashing around the corner cleanly. If you do not wish to form your own corner flashing, you can buy pre-bent pieces and cut them to size, or use a piece of corrugated aluminum, which is easier to bend.

Roof shingle over step flashing

Step flashing on roof peak

Don’t Miss: Shed Eave Overhang

What Is A Wood Stove Pipe

A wood stove pipe is a metal tube that carries the smoke and heated air produced by a wood stove up and out through the roof of your home.

The inside diameter of wood stove pipes are much larger than chimneys, which allows for the slow accumulation of creosote after numerous fires.

Creosote can make its way onto flue tiles, eventually blocking airflow if left unchecked. Pipes should be cleaned each heating season to avoid blockages.

Chimney Flashing Installation On A Standing Seam Metal Roof

Any penetration in a metal roof offers the potential for leaks if it is not flashed properly, and a chimney is no different.

Today on The Metal Roofing Channel, Matt Lane from Metal Construction Solutions and Installations shows how to flash a chimney on a standing seam metal roof using a pre-manufactured curb. The curb is made of welded aluminum and gives superior lifetime protection, and is installed onto the chimney by way of a reglet flashing.

Please note the installation details and methods shown in this video are for reference only. Sheffield Metals recommends following their published installation details or for WTW projects following the required details issued and marked approved for that specific project.

You May Like: Average Shingle Roof Cost

How To Install Step Flashing Where There Is No Wall Corner

If your roof face connects to the wall cleanly without creating a corner, then you dont need to create a corner flashing piece. Instead, you will need to install kickout flashing to help guide the water into the gutter. While some professional roofers will make their kickout flashing by hand in copper, if youre using galvanized steel, it will be too tough to bend properly. Instead, buy a premade kickout flashing piece.

Heres how to install kickout and step flashing:

- Step One: Place your kickout flashing on the base of the roof, snugly against the wall. Briefly remove the piece and apply roofing cement where it will sit.

- Step Two: Place the first piece of step flashing over the end of the starter strip, ensuring it leads directly into the kickout flashing. Use roofing cement and two nails to secure it to the roof deck. Place the nails on the base of the step flashing piece, so youre nailing into the deck. Also place the nails high, so the next course of shingles will cover them.

- Step Three: Once the kick flashing and first piece of step flashing are secure, you have to apply a shingle. First, apply sealant to the base of the flashing. Lay a shingle on top of the flashing and nail it as usual. Notice that the bottom of the shingle covers the flashing base and nail.

- Step Four: Finish the whole shingle course.

- Step Five: To complete the step flashing, follow the same procedure as described above for installed step flashing with a corner piece, starting at step seven.

Seal The Flashing With Caulk

Now it’s time for chimney flashing sealant. Seal the cap flashing by caulking along the mortar joint with polyurethane caulk.

The next step is to mark and cut the grooves in the chimney’s mortar joints to accept the cap flashing. Start at the front of the chimney and mark the third mortar joint up from the roof. Extend this mark around both front corners about 6 in. Now mark the mortar joints on the sides of the chimney so the flashing steps up until you reach the back . Depending on the slope of the roof, each step will jump up one or two mortar joints and should lap over the previous piece of flashing at least 4 in. Mark straight across the back of the chimney to cover the saddle .

Cutting the groove in the mortar is easiest with a grinder and a diamond blade . A circular saw with an inexpensive abrasive masonry blade will also work. Wear goggles, a good dust mask and hearing protection. Cut close to the brick on the lower edge of the mortar joint. This way, the final caulk joint will be less visible. Cut the slots about 1 in. deep and 1/8 in. wide. Make them a few inches longer than you think is necessary, keeping in mind that each piece of cap flashing has to overlap the one below it by about 2 in.

Your new flashing will last longer with a coat of paint. But don’t paint the bare galvanized metal without cleaning it first with lacquer thinner. Another option is to order the slightly more expensive prepainted metal flashing.

Read Also: How Much Shingle Roof Cost

How To Install A Flashing On A Metal Roof

I prefer to use a DSA flashing also known as a dead soft aluminum flashing. This flashing is super thin and very flexible to curve around the humps in the metal roofing. Following is the proceedure for installing the DSA flashing. You can call us with any questions you may have.

On this install we are replaceing a rubber boot flashing that was previously installed. The first picture shows the rubber boot flashing removed and this is what you would start a brand new installation with.

The next step is to clean the roof surface. this one is dirty so we used a scrub pad shown in the following photo. Then you can see how clean we made the roof where we are putting high temp silicone. You also see how thin and flexible the flashing is.

Following making the outline of the flashing with a marker or pencil

Following put a large bead of silicane inside of your mark all the way around the flashing.

Screw it down in a way that its fits tight over the humps of the metal roof.

Use your feet to flatten the flashing down over the contour of the roof.

After screwing it down securely, do another bead of silicone around the edge also put some silicone on all the screws as well. Use your finger or a tool to smooth the silicone around.

I like to put a bead if silicone around the base of the flashing as well.

I also like to put a bead of silicone around the top of the flashing.

Place the storm collar on the pipe and make sure its tight.

Install your cap and your done.