Asphalt & Sbs Roll Roofing Installation Detailshow To Install Roll Roofing

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Roll roofing installation.

Here we include detailed step-by-step instructions for a typical roll roofing installation job using either traditional asphalt roll roofing or SBS roofing. .

This article series describes mineral-granule coated asphalt or SBS roll roofing roofing materials, choices, installations, inspection, defects, roofing repairs, and product sources.

This article includes a description of severe wear and early failure of a mineral-granule-surfaced roll roofing installation over an older metal roof.

We also provide an ARTICLE INDEX for this topic, or you can try the page top or bottom SEARCH BOX as a quick way to find information you need.

Mark Your Working Area With The Chalk

Keep that measuring tape handy because youll need it when you begin the installation process. Keep in mind that rolled roofing is typically installed horizontally.

Grab your measuring tape and chalk line, measure 35 inches up from the bottom edge of the roof, and mark it with the chalk line. Use a meter stick to ensure your line is straight and even across the roof. You dont want crooked roofing!

They Save Time And Labor

Due to their innovative design, ADESO self-adhered membranes are incredibly quick, easy, and cost-efficient to install without the need for torches or extra adhesive. They also offer a granule-free application not having to deal with granules can save a lot of time and fuss during the installation process.

Also Check: How Much Is A New Asphalt Shingle Roof

How To Install Roll Roofing For Maximum Life

Nonetheless roll roofing installations will have a longer life if installed according to the product manufacturer’s instructions, nailed at proper intervals, and with seams properly sealed.

It’s also important to install roll roofing over a smooth sound roof deck.

If the roof decking sags, ponding on the roof surface after rain may reduce its life.

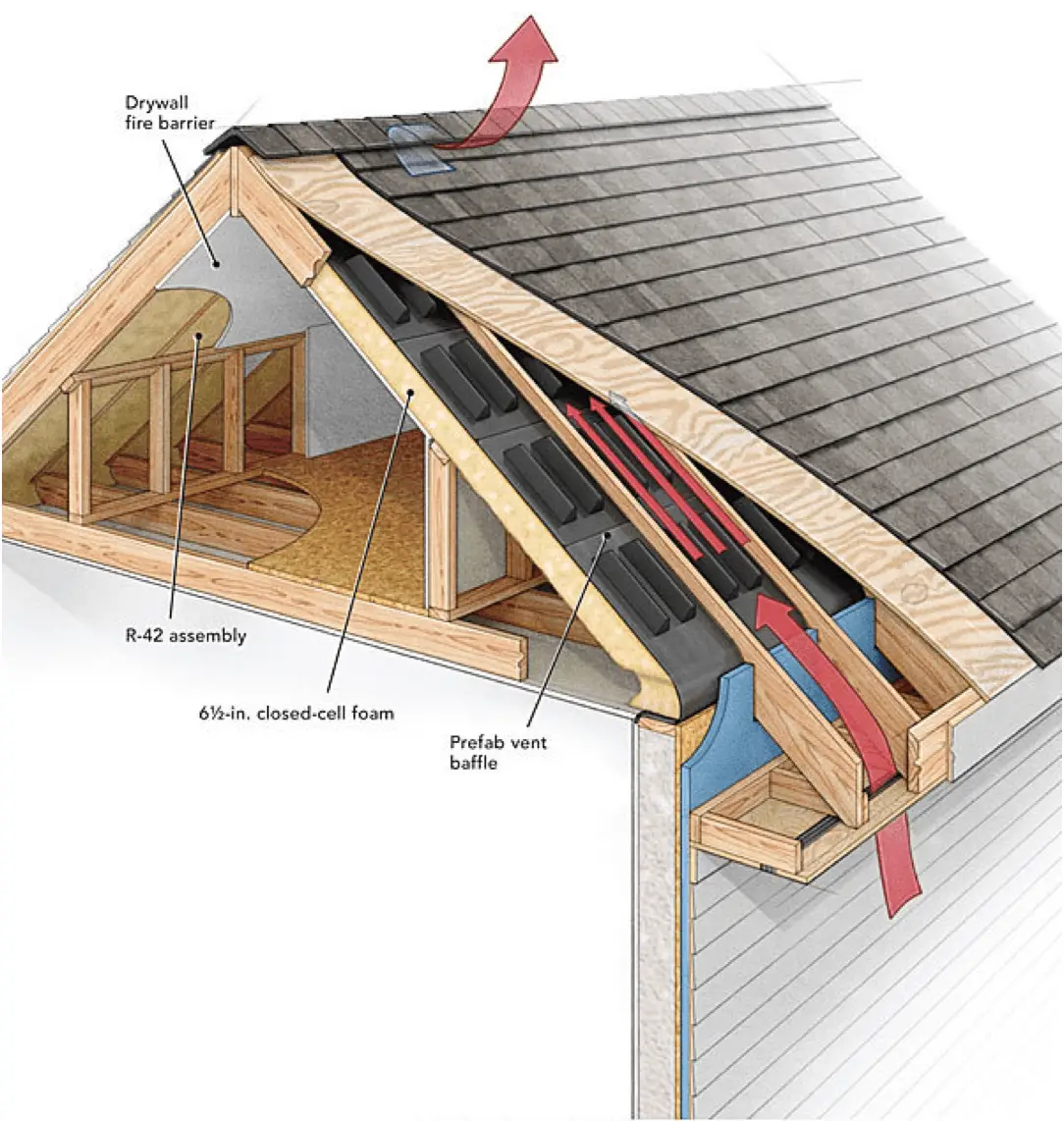

Overlapping strips of asphalt roll roofing are installed over the roof surfaces with overlapped edge joints sealed, usually with a heated asphalt compound, or cold-applied using a similar sealant that functions at lower temperatures.

Sketch courtesy of Carson Dunlop Associates .

Probably in part because asphalt roll roofing is typically used on low slope and nearly flat roofs, it can have an anticipated wear life of less than ten years, often five years.

The life of roll roofing may be extended by coatings.

Roll Roofing Manufacturer’s Installation Instructions & Product Specifications

Illustration: SBS type roll roofing or BUR rolls from MTechnology cited below.

- BP Slate Surface Roll Roofing and BP Mineral Surface roll roofing and related products are described in BP’s FIBERGLASS CAP SHEET RR701 INSTRUCTIONS – retrieved 2022/0717

- BP ASPHALT SHINGLE APPLICATION INSTRUCTIONS , Building Products of Canada, Co., 9510, St. Patrick Street, LaSalle , Canada H8R 1R9 and BP Canada 3703-101 Avenue N.E., Edmonton , Canada T5J 2K8, retrieved 2019/05/01

Suggested citation for this web page

ROLL ROOFING, ASPHALT & SBS INSTALLATION at InspectApedia.com – online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Don’t Miss: What Does A Roofing Consultant Do

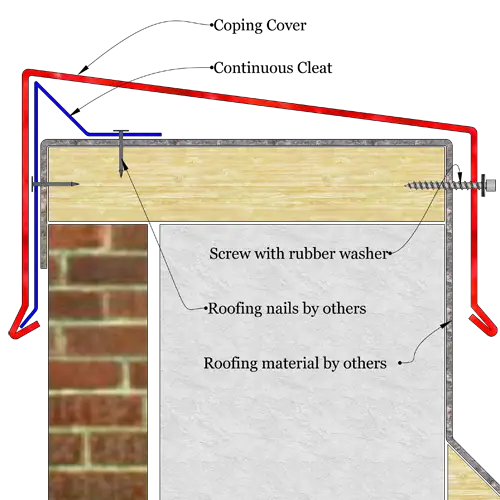

How To Install A Roof Cap

When it comes to finishing off a roof project, the roof capis the most important. A roof cap covers the ridge of a roof in order to deflect water down the sides instead of onto the roofing material. Roof caps are available in many different styles from individual shingles to pre-fabricated caps that run the length of the ridge line. Installing a roof cap is an easy process, but does require some attention to detail for eliminating water damage. Here are the steps to take to install a roof cap yourself.

Tips On Installing Self Adhering Roof Membrane For Flat Or Low Slope Roofs

Low slope areas such as car ports, garages, porches and sun rooms – anything below a 2 / 12 pitch requires special attention. Without the drainage of a steep slope, these roofs can take a hard beating from rain, ice and snow. You’ve probably seen the problem leaks that occur where these low sloped roofs tie in with the main house. To provide you with materials that can meet these challenges GAF has developed a series of self-adhering membranes that go down easy, apply with simple tools, and provide maximum protection. Let’s take a look at these revolutionary low slope products and see how they install.

Liberty is a system for low slopes, with a pitch between 1/2 inch to 6 inches per foot. Designed as a complete roofing system, these membranes serve as a waterproofing for the field of the roof and also are applied as flashings at parapets, perimeter terminations, and typical rooftop penetrations. The Liberty product line consists of three membranes.

The substrate for the Liberty system must be clean and dry. All penetration curbs, perimeter cants, nailers etc, must be in place.

DC Roofing of Arizona

Also Check: Does A New Roof Qualify For Solar Tax Credit

Why Do I Need A Roofing Cap Sheet

A cap sheet is required if you are putting additional insulation on top of the existing roof deck.

It may also be called a modified bitumen membrane, ballast sheet or an ice and water shield.

A combination of layers to create one seamless barrier against the elements.

The underside is covered with sealant to prevent any moisture penetration while the upper surface meets most roof coverings and is appropriate with most building codes.

Typical Roll Roofing Installation Steps & Specifications

Weather conditions: for applying roll roofing: the roof should be clean and dry, and ambient temperatures should be at or above 50°F.Watch out: If you must install roll roofing at lower temperatures store it indoors and warm it to permit unrolling without cracking the material. We can sometimes spot roll roofing installed from too-cold rolls by later failures appearing as cracks, at regular intervals across the width of the material.

Our photo shows our client pointing to a low slope area on a roof where mineral-granule coated asphalt roll roofing was applied after shingles in that location had leaked repeatedly.

Recommended Reading: How To Seal Corrugated Metal Roof

How To Install Roofing Sheet End Cap

The Process To Follow While Installing Roofing Sheets

Cutting the roofing sheet

Many roofing sheets come pre-cut from the manufacturing site, so you wont really need to worry about it. But in case you end up doing it yourself then there are some things that you should keep in mind.

- First, mark the layout with a marker.

- Use proper cutting tools like a circular saw, angle grinder, nibbler or tip snips.

- Do not use excessive heat. Heat can damage the coating, or at the very least, cause discolouration, which never looks good.

- Remove any leftover swarf.

Laying Sheet

This step is the trickiest part, as the sheets need to be aligned in a proper way or youll have to do it all over again.

- Start with cleaning out the roof and taking care of old shingles.

- After cleaning, spread the sheets directly over the purlins, which are attached to the trusses on the roof. Always start laying the sheets from the outside edge.

Screw The Panels

Use appropriate roof fasteners with polycarbonate washers. Lap over the panels by at least 5.5 cm, and adjust the lap so that the last installed panel completes the layout without making additional lengthwise cuts.

In terms of a two-sided roof repeat the steps and install a ridge cap.

Read Also: How To Measure A Roof With Google Maps

What Are They Made Of

- Modified bitumen

- Protective finish

Reinforcement base

The continued development and popularity of roofing felt is due to the weatherproofing and adhesive properties of bitumen, but it is the nature of reinforcing base which dominates the strength and fatigue resistance of the membrane.

Most high-performance felts are made on a polyester fibre base which is more than strong enough for roofing purposes, and has a high-elongation at break which exceeds all demands likely to be met in service.

Polymer modified bitumen

The addition of a polymer to the bitumen improves its properties as a roofing material and in particular its flexibility, strength and fatigue resistance allowing the cap sheet to better cope with thermal and structural movements.

two most commonly used modifying additives are APP and SBS. Whats the difference?

Clean And Prepare The Roof

Before you get started installing, unroll the rolled roofing material on the ground to flatten it out. As the material uncurls, thoroughly clean your roof.

Use a push broom to remove loose debris from the roof. If you notice any nails sticking up from the wood sheathing, hammer them down.

Prepare the roof by ensuring you have an adequate base layer to install the roll roofing over. Roll roofing is usually installed over bare wood sheathing. However, applying roofing felt over the sheathing will help protect against leaking.

Technically, you can install roll roofing over the top of existing shingles. However, when it comes to almost any roofing project, its best to avoid roof layovers and opt for a clean base instead.

It is also a good idea to install drip edge flashing before laying the rolled roof. Drip edge is a type of metal flashing that is installed at the edges of your roof to keep water from getting underneath your roofing materials. Use roofing cement and roofing nails to attach the drip edge flashing around the bottom edge of the roof.

Also Check: What Does Per Square Mean In Roofing

How To Install Self

Self-adhered roofing systems are roofing materials that can be installed quickly through the use of a factory-applied adhesive layer so that contractors can avoid harsh processes like torching.

This article will cover how to install Polyglasss innovative ADESO® self-adhered roofing systems, but first, lets do a quick crash course on what self-adhered technology is and what benefits it offers.

What Is A Roofing Cap Sheet

By: Author Ryan M.

A roofing cap sheet is a metal or plastic material that covers the top of your roof.

It protects the shingles and other materials from damage, which could lead to leaks.

In this blog post, we will discuss how you can find out if you need a roofing cap sheet, what it does for your home, and why its important to have one installed.

You May Like: How Long Do Solar Roofs Last

Snap A Square Reference Line

- A square reference line is important for installing roofing panels evenly. Use the 3-4-5 method to establish a reference line 90 degrees to the eave.

- First, make a mark along the eave three feet from the corner. At that mark, measure four feet toward the ridge. Then, from the original corner, measure five feet and mark where it intersects the second mark.

- Snap a line from the first three-foot mark through the intersection of the second and third marks. Since the Getaway roof is larger, I measured to 21 feet, 28 feet and 35 feet to make my square reference line.

How Do I Maintain My Cap Sheet

A clear coat of mineral-based, water-based, or solvent based sealer should be applied at least once a year to the upper side of the membrane.

This will help protect it from UV rays that can cause the cap sheet to lose its elasticity and shrink.

Also, be sure to stay off the roof surface unless absolutely necessary as you dont want to puncture or tear the cap sheet.

Conversely, if youre planning on re-roofing your home in the near future and think your existing cap sheet may still have some life left in it there are a few steps you can take.

- First, youll want to make sure the upper side of the cap sheet is clean and free of debris before applying any sealant or coating.

- Next, if the upper side isnt smooth its best to lightly scarify that surface in order to give the new coat something to adhere to.

- Finally, youll need to follow the same cleaning and coating procedures for this new layer of cap sheet that you used on the previous surface with one crucial difference when installing the new layer be sure that its sealant overlaps onto the old layer in order to prevent moisture penetration between them.

Don’t Miss: How Do You Put A Tarp On A Roof

Rolled Roofing By Restoration Roofing

Rolled roofing can be a beautiful and very effective roofing material if its installed correctly. I hope this content has been helpful. As always, if you need help with your Memphis roof, give us a call at 901-854-3402! Working with a skilled Memphis roofer who specializes in rolled roofing installation and repairs will ensure your roof is installed correctly and with quality materials.

If you are having issues with your roof, call us to inspect, find the issue and provide a solution that will get you set for years to come. To get in touch with one of our project managers, give us a call at 901-854-3402 or click here to set up a free inspection. We offer free inspections that are easy and completed quickly. Make sure to follow us on and for more tips on taking care of your Memphis roof.

If You Are In Need Of Roof Repair Services

Contact us at Roof Power today to get an estimate on how much it will cost for our professionals to inspect and replace your roofing cap sheet!

We provide fast, professional services that are guaranteed to give you the peace of mind knowing that your roof is well protected from water damage and other weather-related issues.

You May Like: What Is Roof Cement Used For

They Are Durable And Versatile For Any Job

ADESO self-adhered membranes can be specifically tailored to withstand several weather conditions and roofing environments. For example, our specialized Polystick IR-XE is designed for optimum ice and water protection. With our extensive range of options, youll be able to find an ADESO membrane thats perfect for your next client job.

Lay The First Layer Of Rolled Roofing

Once your first layer is cut to size, carefully line up your edges. Lay the first layer down little by little, stretching it as you go to avoid wrinkles. The first layer should cover the length of your roof, as far up as the chalk line. Push the rolled roofing firmly into the wet cement to secure it.

Once the layer is secured by the cement, its time to hammer nails into the layer to secure it further. Use 1 inch galvanized roofing nails and a strong hammer. Make sure you feel steady on the roof before you begin hammering.

Hammer the nails 6 to 10 inches apart across the length of the roof. The nails should only be 1 inch away from the edges. All nails should be flush with the roofing material. Dont leave nails sticking up above the roof.

Recommended Reading: Do Insurance Companies Cover Metal Roofs

Give The Roof A Final Cleaning

Before you can officially say that youre done, bring your push broom back up the roof and clear off any dirt and debris. There shouldnt be too much dirt, but mud from your shoes, twigs, and loose nails may be present.

Once youve brushed off your roof and sprayed it down with a hose , you can step back and admire a job well done.

And thats that! After all these steps have been completed, you have officially installed your very own rolled roof.

What Other Fixtures And Fittings Do I Need On My Roof

There a three main Glazing Bar ranges for use with Polycarbonate Roofing:

Alukap-SS Self Supporting Glazing Bars – Fully Self supporting Aluminium Glazing Bars. No need for any timber on your roof. For maximum quality and lifespan.

Alukap-XR Rafter Supported Glazing Bars – Quality Aluminium Glazing Bars for where you have a rafter in place, wooden or steel or other.

Snapa PVC Snapa Fix Glazing Bars – The PVC Snap fix budget glazing bar.

For example, here is a lean to pergola roof built with our Alukap-XR Glazing Bars and Axiome Sheeting.

Would you like further help with your Roofing Sheet Project?

Simply jump on our Live Chat or via email where our Teams will provide you with all the advice and support you require for your project.

Place Your Order Today Get Same Day Despatch, Free Returns & Flexible Payment!

At Clear Amber Shop you can have total peace of mind with:

You May Like: What To Clean Metal Roof With