Moisture Entering House Wall Improper Roof And Wall Flashing

The picture below is a before picture of a recent rot repair job we did. From the driveway this discolored wall looks like a mildew problem that could easily be cured by cleaning with bleach.

Well thats what I thought too until I was up on a ladder and noticed a small hole and missing and improperly installed roof and wall flashing.

View from above shows a hole on the top section of the fascia and clapboard, hidden from ground view.

Close up of hole. Water has been getting behind the siding. When I pushed on the siding the entire wall flexed which indicated improper roof and side wall flashing not a good sign.

My nail punch pushed easily through the clapboards and plywood sheathing. Another bad sign.

This house is 20 years old the gutter contractor installed this rain divert-er or kick out divert-er which probably kept the majority of water out of this wall.

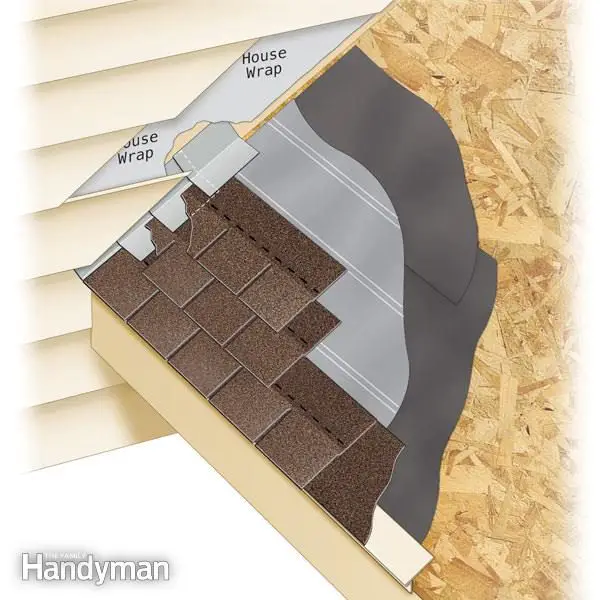

This kick out divert-er certainly helped but was not tall enough and was not installed under the step flashing above it. This house was also missing one final piece of flashing which was the main reason this wall flashing system failed to keep water from entering the building envelope.

If you look closely where the clapboards angle turns and becomes a vertical butt joint this area should have had flashing installed under it and overlapping the clapboard below. Instead if curls out and ends at the but joint.

Recommended Reading: Hydrostop Premium Coat System

How To Install Flashing On An Existing Roof What You Need To Know

Mar 10, 2017 | Roof

Need to know how to install flashing on existing roof? Weve got the information you need to learn about flashing, its functionality, and how to install flashing on existing roof applications.

Flashing itself is quite simple flashing can refer to any impermeable metal barrier used to prevent the ingress of water into roof systems, or to channel water and rain away from your home.

This makes high-quality flashing crucial to the overall health and well-being of your roof. So if your roof flashing is in poor condition, your roof could be at risk of water buildup, rot, and other expensive conditions that could require a roofing contractor to repair them.

To help you avoid costly roof replacements, well go over the basics about metal flashing installation now, and help you replace roof flashing thats gone bad with high-quality, durable metal flashing.

Using Too Many Nails To Install Roof Flashing

The flashing should only be nailed to the wall, not the roof deck. This keeps the roofing shingles intact with no holes, which could allow water seepage. The flashing should not nailed to both surfaces. Buildings, including your home, move in response to temperature changes or shifting in the ground. By not nailing the flashing to the both sections, you are allowing for any slight movements in your homes walls.

You May Like: How To Put A Roof On A Patio

How To Install Endwall Flashing For A Metal Roof Step By Step Guide

When planning your metal roofing project, if you have metal roofing panels that are running up into a wall, youre going to need to install endwall to help control where water flows to protect your structure. Before we begin here is a list of the steps that need to be taken.

- Install sidewall trim prior to the installation of the endwall flashing

- Cut and finish the endwall flashing at the sidewall trim

- Foam closure installation

- Fasten the endwall flashing

At Western States Metal Roofing, our goal is to make the installation of your metal roofing panels easy and stress-free. This installation article will help guide you step by step through installing your endwall trim. To help you visualize this process, please check out our endwall flashing installation detail and the endwall trim installation video to help you even further.

Below, we will walk you through each step of how to install your endwall flashing for your metal roofing project.

To begin, please note that if your roof has a sidewall condition, all sidewall trim must be installed prior to fastening the endwall.

How To Fasten Endwall Flashing

NOTE: Its important to clean off all metal shavings if your project will take multiple days. The shavings can easily rust overnight, staining your roof.

If you have corrugated metal siding panels, your panels should overlap as seen below:

If youre using another material – like stucco – you will need to use a reglet.

You can find step-by-step video tutorials on reglets and much more by going to our learning channel.

You May Like: Do Dentures Cover The Roof Of Your Mouth

Nail The Flashing To The Wall

Slice along the bend line about 4 inches into the first piece of flashing at the bottom of the roof with tin snips. Fold the roof side of the flashing down over the facing board along the roof line. Bend the vertical edge at about a 45-degree angle to make a tab to âkick outâ water, away from the wall and over the bottom of the roof. Nail the flashing to the wall with two galvanized roofing nails and a hammer, instructs Renovation Headquarters.

Lay Down The Shingles

Once youve installed the flashing pieces, install a row of shingles covering the roof and a piece of seam flashing. The first shingles end should extend over the flashing and onto the flat section of the corner flashing piece.

Install the next flashing piece, ensuring that the bend lies in the seam between the roof and the house. The bottom edge of the piece should end immediately below the nail line of the shingles you just laid. Nail the upper part to the wall in the upper corner.

Continue up the roof in that manner as you alternate the flashings with rows of shingles. Make sure that the nails are not visible, except the last one hammered.

Also Check: How Much Solar Energy Can My Roof Produce

What Should I Do If My Chimney Is Leaking

There are several causes of chimney leaks, either roof or masonry related. Best practice is to check chimney flashing first, where the metal or seal at the masonry may have broken. The masonry, i.e., brick, block, or stone, itself can often absorb water, especially if the chimney is made from stone. If the masonry becomes saturated, water will drip through and cause leaks. Defects in the mortar joints can also cause chimney leaks. Lastly, the chimney crown may be cracked and need repairing.

If you are worried about a problem with your roof flashing, request a free estimate here. One of our inspectors will be in touch to walk you through the process. Deer Park Roofing is happy to answer any questions you may have.

This article was authored by Deer Park Roofing, LLC President Nick Sabino.

If you have any other questions about roof flashing or any other part of your roof, contact the experts at Deer Park Roofing in Louisville, KY

Tags:

Cut Along The Fold Line

After installing all the pieces, youll eventually reach the roof peak. Since the roof peak is two slopes that meet, youll have to do this step for both sides.

Recommended Reading: How Much For Roofing Per Square

Letting The Siding Touch The Roof Surface

There should be a gap of at least 2 inches between the bottom of the exterior wall and the top of the roofing shingles. This gap is important to prevent water damage. If the exterior wall covering touches the top of the shingles, it can wick up moisture from the roofs surface. This moisture can lead to peeling paint or wood rot along the junction area. The spacing provides an air gap, which allows water to drain out completely and the siding ends to dry out.

this infographic.

How To Find Your Roof Slope

Find the slope of the roof. Label one edge of a 2-ft. square scrap of plywood or cardboard roof and lay the labeled edge against the roof. Draw a level line at least 12 in. long on the plywood and label the line run.

Measure 12 in. along the run line and make a mark. Use a framing square to draw a square line from this mark down to the edge of the plywood labeled roof. Label this line rise. Measure the length of the line labeled rise to determine the slope, expressed as inches of rise for every 12 in. of run. In our case, the roof slope is 6 in. of rise for every 12 in. of run.

You May Like: What Kinds Of Roofs Are There

Installing The New Vent Pipe Flashing

Now it gets a little tricky to install the new vent pipe flashing you first need to work the opening of the rubber where the pipe will pass through by stretching it. You just want it flexible so the pipe will pass through easily.

Now put a small amount of silicon on the inside of the rubber flashing and spread it around so it will slip over the pipe without problem.

Lower the flashing onto the pipe rotated 90 degrees or the opposite way that it came off.

At the same time you want to lift the top two rows so that the metal flashing can be rotated under the middle row of shingles.

BEFORE the flashing is pressed down to the surface of the roof you want to apply a bead of silicon on the shingles about an inch in from the edges.

Now press the aluminum flashing flush to the shingle surface.

Nail the bottom two corners about an inch in from each side the same position as when you took the flashing off.

Nail the two middle edges of the flashing.

Nail the top shingles in place through the flashing on the outside corners.

How To Install A Roof Plumbing Vent Flashing Boot

Installing a roof plumbing vent is typically an easier task than flashing a chimney. Here is how you do it:

- Step One: Install shingles as normal up to the base of the plumbing vent.

- Step Two: Place the flashing or boot onto the plumbing vent, so the base is resting on shingles. Momentarily lift the boot and apply sealant to hold the flashing in place.

- Step Three: Firmly push the flashing back down into place.

- Step Four: Install the next course of shingles. When you reach the plumbing vent, allow the shingles to overlap the top of the flashing.

- Step Five: To make room for the vent itself, cut out a circular piece of the shingles, as shown below.

- Step Six: To secure the circular edge of the shingle, apply roofing cement beneath it. Ensure you also nail it where you normally would.

Do you need information about how to install the other kinds of roof flashing? IKO has already explained how to install drip edge flashing and how to install metal valley flashing.

Old roof plumbing vent flashing boot

New roof plumbing vent flashing boot

Don’t Miss: How Much Should It Cost To Replace My Roof

How To Install Step Flashing On Your Roof

Lee has over two decades of hands-on experience remodeling, fixing, and improving homes, and has been providing home improvement advice for over 13 years.

- Working Time: 1 hr, 30 mins

- Total Time: 2 hrs

- Yield: 6 feet of step flashing

- Skill Level: Intermediate

- Estimated Cost: $50 to $75

An effective system of step flashing on a roof is crucial to maintaining not just your roof but your entire home. Mold, rot, insects, and structural failure are the main byproducts of moisture intrusion inside walls, attics, roofs, and floors. Learn how to install step flashing to keep your house dry and in good condition.

Roof Flashing In A Nutshell

An incredibly versatile flashing material option is Polyisobutylene, which our Wakaflex comprises. It requires no specialist tools and is compatible with most roof materials, making it quick and easy to install using the techniques above.

Though flashing isnt the most exciting part of roofing, it is undoubtedly one of the most vital elements in making your roof safe, secure and watertight. Check out the range of roof flashings we offer, using the most durable and flexible materials.

Also Check: Does Choice Home Warranty Cover Roof

What Is It Made Out Of

Step flashing comes in many different materials. The most common and cheapest kind of step flashing is aluminum. Aluminum step flashing is durable and will never rust, but it is very flimsy and can be damaged easily during installation. The second most common step flashing material is galvanized steel step flashing. This is much thicker and stronger, but it can rust over time. Finally, theres copper step flashing. This step flashing can technically last forever as long as it does not come in contact with metals that are not copper. Copper is the most expensive material to make step flashing out of, but it works great on lifetime shingles and designer shingles.

How To Install Roof Flashing On A Shingle Roof

About the Author

Jose Rodriguez

Jose Rodriguez founded Red Canyon Roofing with Arturo Vasquez in 2015. Since then he has overseen the growth of the company, and is passionate about finding meaningful ways for Red Canyon Roofing to make an impact in their community.

Tags:

Roof flashing, while it may not be a widely known concept to the general public, is a vital part of the roofing process.

Roof flashing seals areas of the roof that are prone to leaking when it rains or snows. Typically composed of a thin metal material, you should place flashing in areas where water runs off or does not have a solid seal. Before we go over the 5 simple steps to install roof flashing, lets take a look at the different types.

Read Also: Are Metal Roofs Cheaper Than Regular Roofs

What Is A Roof Flashing And Why Is It Important

While roofs are purposely constructed to allow rainwater run-off, they can often have several vertical features or protrusions, such as chimneys, parapet walls, half walls, dormers, skylights, vent pipes, and the like, where water can pool up and/or drip into the crevices between. The areas can eventually become damaged and allow water seepage and leaks into the house. To prevent this, professional roofers apply roof flashing to divert rainwater down the sides of the vertical surfaces, keeping the water from stagnating.

Roof flashing is typically a thin metal material fabricated from rust-resistant metal, such as G-90 galvanized steel, a frequently used flashing material, copper, or aluminum. Depending on the company, flashing may even be available in lead or zinc alloy.

Steel, copper, and aluminum are particularly used because of how malleable these metals are, rendering them easier to shape. However, the homeowner should note the different characteristics of each metal:

Flashing closes the joints between the roof and the roof features in order to protect the house from erosion and leaking. A lack of flashing or poor flashing installation can also lead to wood rot, potential shingle damage, or deck collapse, among other issues.

Flashing comes in various shapes and is used for different areas on the roof . For this reason, different flashing types will be installed in dissimilar ways, and the cost of flashing will vary.

Read Also: Skylight On Metal Roof

Professional Tips To Ensure Leak

Most homeowners don’t associate plumbing work with their roofs. But many roofing contractors, plumbers, and inspectors often need to be on the roof to perform their jobs.

If you’re working on your home’s plumbing vent, replacing the roof, or just doing an annual inspection, you may need to repair or replace the roof flashing.

Read Also: How Many Layers Of Roof Shingles Are Allowed In California

Flashing Under Aluminum Siding

Im taking estimates for replacing my roof. Three contractors have not given me a solid answer as to how they will deal with the flashing where the roof meets aluminum sided dormers or aluminum sided walls. The roof has three levels. One suggestion was to make a cut in the aluminum siding parallel to the roof line, replace the flashing and then insert an aluminum covered board over where the cuts were made. Doesnt seem right to me.

I couldnt give a solid answer either. Mentally, Ill have a Plan A that circumstances can cause me to switch to Plan B, then Plan C and next thing I know, the reality of the specific situation might have me on Plan H by time I get it flashed.

The method we use is to score the siding deep with a fresh straight blade 1 1/2 inches up from the roof deck, carefully remove the waste and J channel and install 3in tall step flashing under the siding. Then shingle normally. We use a urethane base caulk to glue the J back in place, supporting it with shingle scrap until cure. Good luck, its a PITA whatever you do.

We just remove the aluminum siding, ice and water, re-flash and re-install the old siding. It has never proven too difficult.

Is your J channel sitting on the roof deck?.,.If the step flashing was not nailed to the wall then a nail bar can be used to remove the old and install the new.

And yes.,if you go in like a bulldozer with a tear off spade then yeah you could destroy the siding and charge the customer.