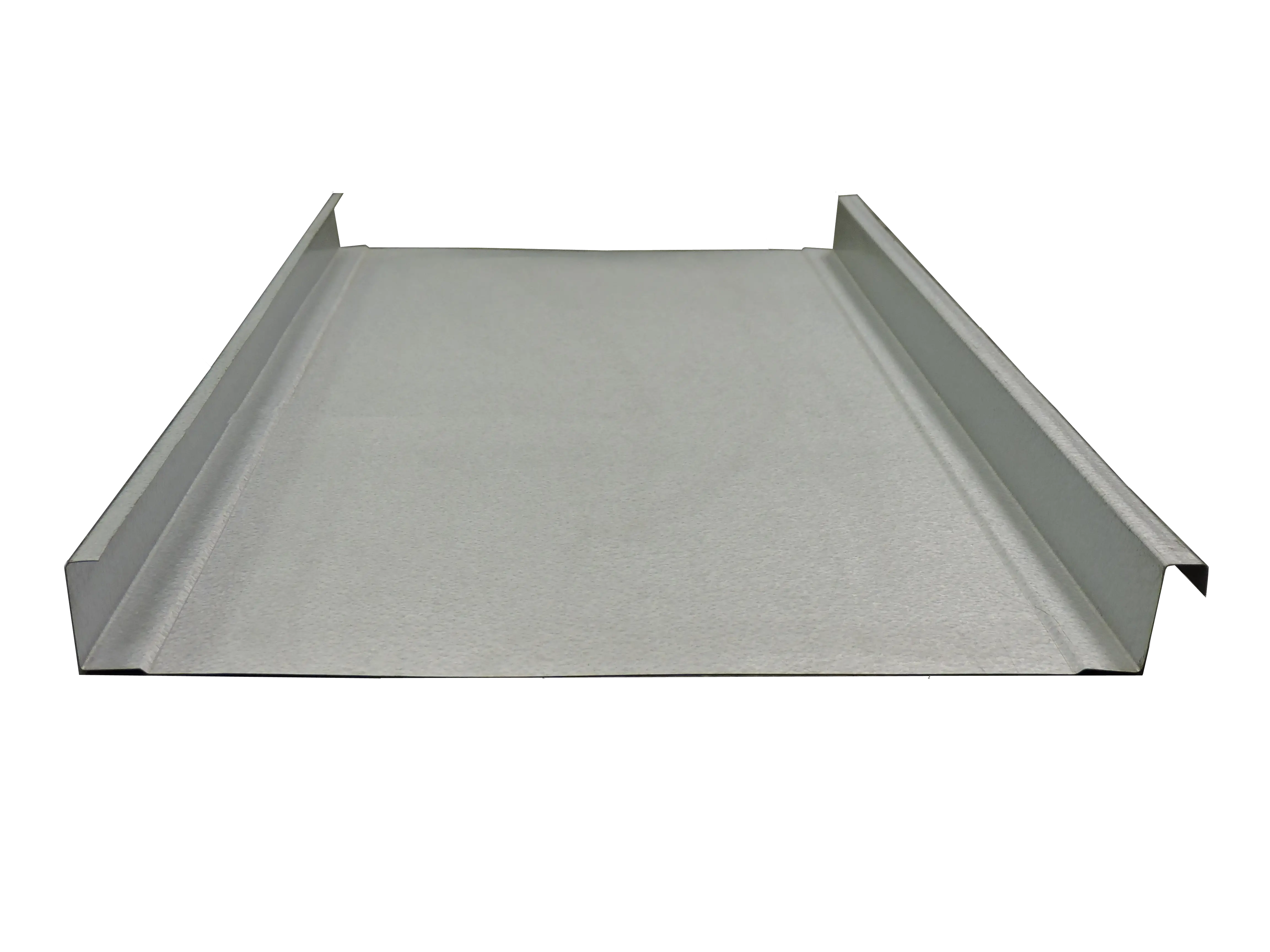

Vr16 Ii Vertical Rib Standing Seam

Nucor VR16 II is a vertical rib standing seam panel that is perfect for architectural requirements in todays marketplace. This weathertight system is an ideal solution for buildings with hips and valleys. Panels are installed with concealed fastener clips that allow for thermal movement & mechanically seamed for weathertight installation. Both VR16 II-90 and VR16 II-360 seaming profiles are available.

Price And Value Come Together With Universal Standing Seam Steel Roofing

Universal Standing Seam panels are 16 wide, making them work well on both large and small structures. The 1.5 tall interlocking vertical seams offer great watertightness even on lower pitch roofs. Installation is made fast and easy with the built-in fastening hem that is concealed from view yet has slotted holes to naturally allow for the metals expansion and contraction, no matter how wide of temperature swings your reign is prone to experience.

The Universal steel, metal roofing panels come in custom lengths produced at the factory specifically for your building. We also offer standard length panels which work exceptionally well for smaller accent roofs such as porches and overhangs. They can either be cut on the job site to match your building requirements or be joined together with horizontal laps. Our many available colors have been carefully chosen to offer something for virtually every home or accent roof.

Our robust baked-on PVDF coatings have been designed for top performance in all climates. Include our fade and chalk resistance warranty, Universal Standing Seam will be a long-term, reliable roof for your home.

Outstanding performance, with an outstanding warranty, are built into every Universal Standing Seam project.

What Is The Cheapest Standing Seam Metal Roof

Aluminum is the most affordable standing seam roofing material. It may dent more easily than steel, but it offers quality corrosion resistance and can be painted in a variety of colors, which can allow for a more congruent aesthetic on any type of home which makes it a popular choice for standing seam metal roofing.

Recommended Reading: How To Build A Flat Roof Shed

How To Layout Pipe Penetrations

Pipes and other penetrations will also factor into your layout. You don’t want the seam of a panel to land where a penetration is located. If theres a pipe in the panel seam, you will need to adjust the sizes of the first and last panels to compensate for the adjustment.

If you are working on a newer build or you have access to the pipe runs, you can also cut the pipe and rerun it to where it will land in the middle of a panel.

If you are removing a pipe, make sure the cuts fall flush or below the roof line. You do not want any pipe pieces creating bumps on the metal roofing panels.

Next, cover the hole with a piece of flat stock. For example, if you have a 4 hole, it is recommended you cover the whole with a 16 x 16 piece of flat stock.

Fasten the flat stock using pancake screws 2 apart around the perimeter.

Next, seal with a 4x 4 piece of sharkskin underlayment.

Msl Standing Seam Panel

The Mueller Snap Lock standing seam panel is one of the most versatile metal roofing panels made. Whether using MSL on a commercial metal building or on a residential metal roofing application, its structural performance is unsurpassed. The bold profile of the MSL and the many color choices can satisfy any visual need that might arise. Having to choose form or function when making a roofing decision is no longer an issue when Mueller Snap Lock is your choice. Its structural brawn and obvious beauty make it a metal roof panel frequently used in many applications.

You May Like: Don Poss Roofing Inverness Fl

Klein 200 Double Lock 24 Gauge Metal Roofing Panels

The Klein 200 metal roofing panel is minimum 24-gauge galvalume steel. The panels have a 18.5″ coverage, 2″ tall standing seam rib with a 180 degree mechanical lock seam. The panels are manufactured from 24-gauge Galvalume coated steel that conforms to ASTM A792, Grade 50, with a minimum yield strength of 50,000 psi.

The Klein 200 metal roofing panel features structural performance as well as architectural aesthetics. The panels can be factory formed and/or fabricated, for all substrates, at project locations. Utilizes concealed fasteners with a fixed and/or floating clip system. The floating clip system reduces the effects of thermal stresses on the panels helping to maintain a beautifully smooth, and uniform appearance, despite fluctuations in temperature.

The Klein 200 metal roofing panel is a mechanically seamed, vertical leg, standing seam roof system that combines a 2-inch tall slim rib with an exceptional uplift resistance. The panels are designed to withstand the most rigorous weather conditions. The panel is available in 16″ width up to 18.5″ and allows for the installation directly over purlins and bar joists.

Advantages Of Standing Seam Metal Roofing

The interlocking panels of a standing seam metal roof ensure that no fasteners are exposed to the elements where they can deteriorate over time. All metal roofing systems are durable, but the fasteners sometimes must be replaced when they wear out. With a standing seam metal roof, this doesnt happen because there are no exposed fasteners.

A standing seam metal roof is also unique and different from other metal roofing systems in that the panels arent pinned down, so they can expand and contract with the weather, allowing for more freedom of movement and less breakage.

As with all metal roofing systems, standing seam metal roofing is also durable, customizable, long- lasting, eco-friendly, and energy efficient. These are all the things weve come to love about the increased installation of metal roofing systems.

Also Check: How To Generate Roofing Leads

Standing Seam Metal Panel Profiles

When we say profile we mean the shape and how panels are seamed together. Roof Experts will help you to decide which profile fits best for your building. The choice is based on such factors as the roof type and its pitch, architectural features, surroundings, weather conditions, and so on. There is a number of standing seam types which we will discuss further down.

Dimensions And Metal Thickness

- Standard panel width approx. 530 mm

- Common panel widths 400 mm to 600 mm

- Metal thicknesses 0.7 mm/0.8 mm

- Normal panel length up to 10 m

- In special cases up to 16 m

- Standard transport length is 7 m

The international standard size for roofs in double standing seam systems is a panel width of approx. 530 mm and a metal thickness of 0.7 mm. We recommend limiting the panel width to 430 mm and the metal thickness to 0.8 mm for mono pitch roofs with overhangs based on practical construction experience. This measure prevents noises that can occur in strong winds due to the natural curvature of the panels.

The generally common maximum panel length is 10 m. Using our clips, this can be extended to 16 m. However, the roof inclination then remains limited to max. 30°. In this case, panel attachments and connection details must be adapted to the increased length variation.

If the max. possible panel length is insufficient, individual lengths can be connected using cross seams.

Also Check: Is Tesla Solar Roof Available

Features Of Rheinzink Double Lock Standing Seams

Double standing seam coverings have many impressive benefits. The quality of RHEINZINK products stands out from that of competitors’ products due to our use of TÜV-certified titanium zinc, referred to as Quality Zinc. The following product features are particularly noteworthy:

- The particularly delicate seams have an attractive, slim appearance and ensure the harmonious integration of roof surfaces in traditional or moderner buildings

- Double standing seams are ideal for shallow roof slopes and can be used starting from a gradient of 3°.

- They can be perfectly adapted to various building elements for existing buildings with more complex architecture. Tapered, concave or convex rounded surfaces can be accurately formed

- Standing seam panels up to 7 m long are economical to fit. Panel lengths of up to 16 m can be flexibly employed, including on roofs with large surface areas. We can provide rental machines for processing greater lengths on site.

- The seams are rainproof and so protect the building structure against wind and weather

Planners and professional specialists can also decide whether to produce the double standing seams manually or using a profiling machine.

Panel Layout: Standing Seam Metal Roofing Installation

When youre getting ready to install a standing seam roof, youll need to prepare your installation by preparing how youll lay out your metal panels. Western States Metal Roofing has the expertise to help with this. Weve created step by step written instructions and pictures that illustrate each step on panel layout.

Follow along by watching our step by step panel layout video:

This article is intended to support the video. Follow the instructions within the video and refer back to this article if you need a written copy of the instruction.

In this article, we will tell you everything you need to know to plan the layout for your standing seam panels including:

- Planning your panel layout

- Preparing your roof for panel installation

You May Like: How Do You Get Moss Off Of Roof Shingles

Projects Using Cfr Insulated Standing Seam Roof Panels:

- Gary Jet Center: New, energy-efficient airplane hangar utilizes 40,000 sq. ft. of CFR insulated standing seam roof panels.

- Application: Aviation

- State: Indiana

- Color: Polar White

Nucor Cfr Standing Seam Roof System

Nucor CFR standing seam roof system is a raised seam metal roof, designed to float to accommodate thermal expansion & contraction. It has been extensively tested to ensure the highest level of performance for weathertightness and structural integrity, and approved for wind uplift, hail and fire resistance. Nucor Vise-Lock 360º seaming profile is available with this panel.

Don’t Miss: Does Replacing A Roof Increase Home Value

Kynar Paint Technologies Allow Metal Roofing To Retain It’s Like New Curb Appeal For Decades

At McElroy Metal, we’re proud to have one of the most robust roofing product lines in the industry. From exposed fastened to standing seam and even insulated metal roofing systems, we’ve got you covered.

In fact, we even offer products for unique applications like curved standing seam panels, patented recover solutions and panels that can be jobsite roll formed to allow continuous panel lengths up to 250′ long.

Learn more about our product options below or simply Contact Us, we’re here to help.

Standing Seam Metal Roofing

Within the metal roofing family are standing seam metal roofing panels and these panels contain both male and female legs that are installed with clips to the substructure of your roof. There are also some options that have clipless panels. Both of these options do not use exposed fasteners while the panels are being installed.

There are many different types of projects and applications that standing seam systems can be used for. Since this type of roofing system has interlocking seams that connect the roofing panels, the roof gets a very unique and appealing look.

Another benefit is these seam systems are made from high quality materials that provide homeowners with a very low-maintenance roofing system. Standing seam metal roofing is also incredibly durable and weatherproof.

Read Also: What Is The Best Type Of Roof Ventilation

Need More Help With Standing Seam Metal Roofing Installation

For panels and accessories needed for your standing seam installation, go to the Western States Metal Roofing website to see our catalog, and request a quoteor metal color sample as there are hundreds of colors to choose from.

Looking for more homeowner guides and step-by-step installation help? Be sure to subscribe to our Youtube channel as we release new installation videos weekly. You can also find everything you need at the Western States Metal Roofing Learning Center to help you have an easy and successful installation.

What Is A Standing Seam Metal Roof

Standing Seam can be defined as a seam made by turning up two adjacent edges and folding the upstanding parts over on themselves, therefore creating a seamless look. Standing Seam metal roofing systems use hidden fasteners, meaning the hardware used to secure the panels to the substrate are hidden beneath the panels instead of exposed on top of them. Typically, standing seam panels are completely flat or striated, with the ridges or bumps being at the seams . They use a raised, interlocking seam to join one panel to another, allowing for crisp, clean lines.

Don’t Miss: What Size Plywood Do You Use On A Roof

Benefits & Advantage Of Cfr Insulated Standing Seam Roofing:

- Weathertight vertical side seaming and installation savings with fewer side joints to seal

- Factory-cut panel ends, factory notching and factory-swaged ends eliminate field work and erection costs

- Factory-installed backer plates at the endlaps eliminate pre-drilling for special fasteners

- Installed from the top side to provide concealed clips and fasteners

Should Be No Exposed Fasteners

Easily one of the biggest benefits of standing seam metal roofing is the fact that no fasteners are visible on the surface, which means they arent exposed to UV, moisture, wind, and other elements that can cause a fastener to wear or fail over time. Also, standing seam systems dont put holes in the panels that are protecting your structure. Plus, some people see fastener heads as unsightly, which is why using a standing seam system to hide them is common.

Also Check: How To Use Wet And Forget On Roof

How Much Does A Metal Standing Seam Roof Cost

Standing Seam Roof Costs Materials. While material will usually not make up a majority of your total metal roof cost, they do encompass a good percentage. Like any material, there are basic and superior metal roofs. Nonetheless, expect to pay between $400 and $650 for standing seam metal roof panels.

What Is A Metal Roof Panel

Metal roofing panels have been a workhorse in the construction industry since the turn of the century. Initially, small pieces of copper and zinc were hand formed by craftsman. The slow and manual process created beautiful but often price prohibitive roofs.

Over time, rolling manufacturing lines were introduced. This mechanization enabled a quicker and more efficient production and install process as roll formed sheets routinely covered a 3′ wide section of the roof with one panel running from eave to ridge.

This advancement made metal roofing both durable and affordable. The only piece left of the puzzle was the appearance. In the early days, roll formed panels had a simple rounded corrugation and finish options were limited at best. But how the industry has changed! Todays savvy consumers can choose from multiple profiles, paint systems, substrates and extensive color selections. Thanks to these advances, metal roofing is one of the most cost effective, beautiful and environmentally friendly roofing choices available.

You May Like: What To Know About Getting A New Roof

Less Qualified Contractors Have Experience Installing Standing Seam Roofing

Finding a contractor who is qualified, skilled, and experienced in metal roof installation is vitally important, especially because standing seam systems require careful craftsmanship. Since standing seam installations may be considered too complicated or tedious, there are far fewer contractors to choose from who have a proven track record and the relevant experience.

Standing Seam Metal Roof Maintenance

Other metal roofing systems require the use of fasteners, which means that while they require little maintenance, you still have to check for loose or damaged fasteners and replace them. However, a standing seam metal roof doesnt have fasteners that go through the metal, so you dont need to perform this type of maintenance.

Upkeep is always essential, but a standing seam metal roof requires much less of it. Inspecting for low hanging branches, other metal, or debris and clearing it off is all you should have to do.

Also Check: Where Do Roof Rats Live

Whats The Difference Between Each Type Of Standing Seam Panel

Each Standing Seam panel is installed and secured to the roofs substrate differently. Their names each reflect the different ways they come together.

Mechanical Lock panels are mechanically fastened to one another, meaning a special tool called a seamer is needed to lock them together. These panels use a clipped system that fastens them to the substrate. Then, you use an electric or hand seamer to press them together mechanically, which bends each panel over one another and creates a lip. Mechanical Lock panels require a more advanced installation.

Mechanical Lock

Tru Snap metal panels have two identical female legs and snap together. With Tru Snap, the male leg is clipped, and that clip is fastened directly to the decking. These panels require more parts and pieces, making installation a bit more difficult. However, Tru Snap can be run with longer panels due to the clipped system it uses, which allows the panels to move more freely through expansion and contraction.

Tru Snap

Nail Strip metal panels also have two identical female legs. The big difference is that with Nail Strip panels, the male leg has a perforated nail flange used to fasten the panel directly to the decking. Nail Strip is a bit easier and more straightforward when it comes to installation, however it is limited by how long you can run the panels since theyre screwed directly to the decking.

Nail Strip

Final Thoughts On Standing Seam Metal Roofing

Standing seam metal roofings variety of options and versatility makes it an excellent choice for virtually any building type, including commercial, residential, architectural, structural, and beyond.

To wrap up, what makes standing seam metal roofing different are these four parts:

- A concealed fastener

Recommended Reading: How To Install Thatch Roofing